The Role of Polyester Spiral Fabric in Sludge Dewatering Systems

Advantages of Polyester Spiral Fabric in Sludge Dewatering

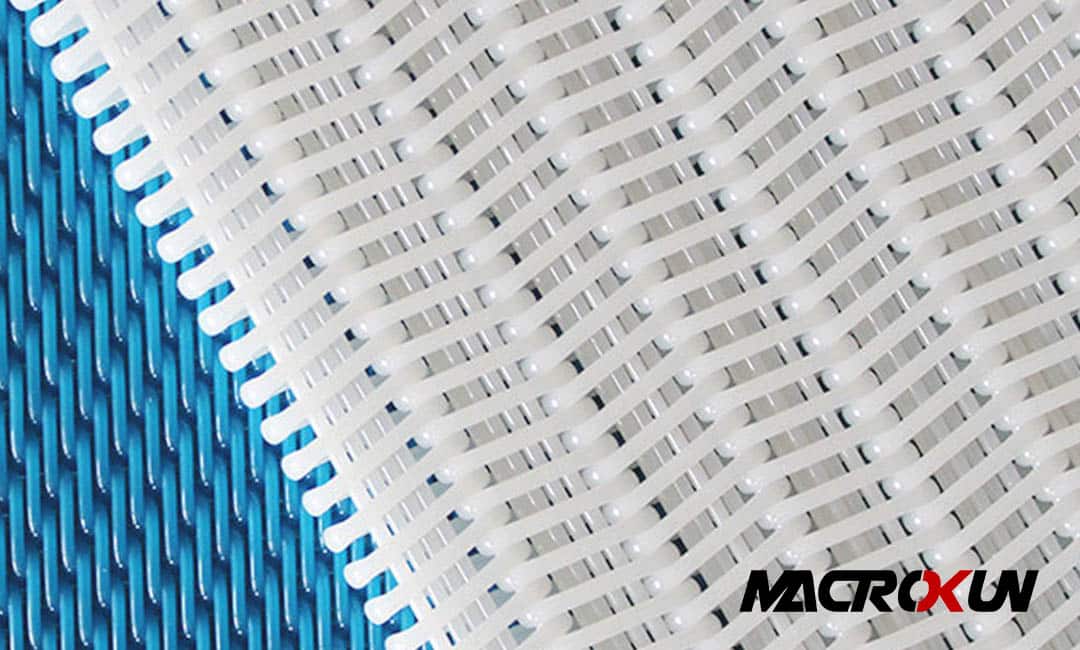

Polyester spiral fabric has emerged as a pivotal component in the realm of sludge dewatering systems, offering a multitude of advantages that enhance both efficiency and effectiveness. One of the primary benefits of polyester spiral fabric is its exceptional filtration capabilities. The unique spiral design allows for optimal flow rates while maintaining a high level of filtration precision. This characteristic is particularly crucial in sludge dewatering, where the removal of excess water is essential for reducing the volume of waste and facilitating easier handling and disposal. By effectively separating solids from liquids, polyester spiral fabric contributes significantly to the overall efficiency of the dewatering process.

In addition to its filtration efficiency, polyester spiral fabric is renowned for its durability and resistance to wear and tear. Unlike traditional fabrics, which may degrade over time due to exposure to harsh chemicals and mechanical stress, polyester spiral fabric is engineered to withstand the rigors of continuous operation. This durability translates into longer service life and reduced maintenance costs, making it a cost-effective choice for wastewater treatment facilities. Furthermore, the fabric’s resistance to chemical degradation ensures that it can perform reliably in various sludge compositions, which may contain corrosive substances or abrasive particles.

Another notable advantage of polyester spiral fabric is its lightweight nature, which simplifies installation and handling. The ease of installation not only reduces labor costs but also minimizes downtime during maintenance or replacement. This aspect is particularly beneficial in large-scale operations where efficiency is paramount. Additionally, the lightweight design allows for easier maneuverability within the dewatering system, enabling operators to make adjustments or repairs with minimal disruption to the overall process.

Moreover, polyester spiral fabric exhibits excellent drainage properties, which are essential for effective sludge dewatering. The fabric’s structure promotes rapid drainage of liquids, thereby accelerating the dewatering process. This rapid drainage capability not only enhances the efficiency of the system but also contributes to improved overall performance. As a result, facilities can achieve higher throughput and better quality of dewatered sludge, which is crucial for meeting regulatory standards and ensuring environmental compliance.

Furthermore, the versatility of polyester spiral fabric cannot be overlooked. It can be tailored to meet specific operational requirements, including variations in pore size and thickness. This customization allows facilities to optimize their dewatering processes based on the unique characteristics of the sludge being treated. By selecting the appropriate fabric specifications, operators can enhance the performance of their systems, leading to improved outcomes in terms of both efficiency and effectiveness.

In addition to these practical advantages, polyester spiral fabric also supports sustainability initiatives within wastewater treatment facilities. By improving the dewatering process, facilities can reduce the volume of sludge that requires disposal, thereby minimizing their environmental footprint. This reduction in waste not only aligns with regulatory requirements but also contributes to broader sustainability goals, making polyester spiral fabric an environmentally responsible choice.

In conclusion, the advantages of polyester spiral fabric in sludge dewatering systems are manifold. From its superior filtration capabilities and durability to its lightweight design and excellent drainage properties, this innovative material plays a crucial role in enhancing the efficiency and effectiveness of dewatering processes. As wastewater treatment facilities continue to seek ways to improve their operations and meet regulatory standards, polyester spiral fabric stands out as a reliable and versatile solution that supports both operational excellence and sustainability.

Comparison of Polyester Spiral Fabric and Traditional Dewatering Fabrics

In the realm of sludge dewatering systems, the choice of fabric plays a pivotal role in determining the efficiency and effectiveness of the process. Among the various options available, polyester spiral fabric has emerged as a noteworthy alternative to traditional dewatering fabrics. To understand the advantages of polyester spiral fabric, it is essential to compare it with conventional materials, which have long been the standard in the industry.

Traditional dewatering fabrics, often made from woven polypropylene or polyester, have been utilized for years due to their established performance and reliability. These fabrics typically feature a flat structure that allows for the passage of water while retaining solid particles. However, this design can sometimes lead to issues such as blinding, where the fabric becomes clogged with fine particles, reducing its permeability and overall efficiency. Consequently, operators may find themselves frequently replacing or cleaning these fabrics, which can result in increased operational costs and downtime.

In contrast, polyester spiral fabric introduces a unique design that enhances its performance in sludge dewatering applications. The spiral structure of this fabric allows for a more open and flexible configuration, which significantly reduces the likelihood of blinding. As a result, the polyester spiral fabric maintains its permeability over extended periods, enabling more efficient water drainage and solid retention. This characteristic not only improves the overall dewatering process but also minimizes the need for frequent maintenance, thereby lowering operational costs.

Moreover, the durability of polyester spiral fabric is another aspect that sets it apart from traditional options. While conventional fabrics may degrade over time due to exposure to harsh chemicals and mechanical wear, polyester spiral fabric is engineered to withstand these challenges. Its robust construction ensures that it can endure the rigors of continuous use in demanding environments, leading to a longer lifespan and reduced replacement frequency. This durability translates into significant cost savings for facilities that rely on sludge dewatering systems.

Additionally, the versatility of polyester spiral fabric cannot be overlooked. It is available in various configurations and can be tailored to meet specific operational requirements. This adaptability allows for the optimization of dewatering processes across different types of sludge, whether it be municipal wastewater, industrial effluent, or other challenging materials. In contrast, traditional fabrics may not offer the same level of customization, potentially limiting their effectiveness in certain applications.

Furthermore, the environmental impact of using polyester spiral fabric is an important consideration. As industries increasingly prioritize sustainability, the longevity and efficiency of this fabric contribute to reduced waste and lower energy consumption in sludge dewatering operations. By minimizing the frequency of fabric replacement and enhancing the overall efficiency of the dewatering process, polyester spiral fabric aligns with the growing emphasis on environmentally responsible practices.

In conclusion, the comparison between polyester spiral fabric and traditional dewatering fabrics reveals several compelling advantages of the former. Its innovative design reduces the risk of blinding, enhances durability, and offers versatility in application, all while promoting sustainability. As industries continue to seek more efficient and cost-effective solutions for sludge dewatering, polyester spiral fabric stands out as a superior choice that meets the evolving demands of modern wastewater management. By embracing this advanced material, facilities can optimize their operations and contribute to a more sustainable future.

Maintenance Best Practices for Polyester Spiral Fabric in Dewatering Systems

Polyester spiral fabric plays a crucial role in the efficiency and effectiveness of sludge dewatering systems, serving as a vital component that enhances the overall performance of these systems. To ensure that this fabric operates at its best, it is essential to implement maintenance best practices that not only prolong its lifespan but also optimize its functionality. Regular maintenance is key, as it helps to prevent the accumulation of sludge and other contaminants that can hinder the fabric’s performance.

One of the primary maintenance practices involves routine inspections of the polyester spiral fabric. These inspections should focus on identifying any signs of wear, tear, or damage that may have occurred during operation. By conducting these inspections regularly, operators can detect potential issues early on, allowing for timely repairs or replacements. This proactive approach not only minimizes downtime but also ensures that the dewatering system continues to operate efficiently.

In addition to inspections, cleaning the polyester spiral fabric is another critical aspect of maintenance. Over time, sludge and other materials can build up on the fabric, leading to reduced permeability and efficiency. Therefore, it is advisable to establish a cleaning schedule that aligns with the operational demands of the dewatering system. Cleaning methods may vary, but high-pressure washing is often effective in removing stubborn deposits without damaging the fabric. Furthermore, using appropriate cleaning agents can enhance the cleaning process, ensuring that the fabric remains in optimal condition.

Moreover, it is essential to monitor the operating conditions of the dewatering system, as these can significantly impact the performance of the polyester spiral fabric. Factors such as temperature, pressure, and flow rates should be regularly assessed to ensure they remain within the recommended parameters. Deviations from these parameters can lead to increased wear on the fabric, ultimately affecting its efficiency and lifespan. By maintaining optimal operating conditions, operators can help to preserve the integrity of the polyester spiral fabric and enhance the overall performance of the dewatering system.

Another important maintenance practice involves proper storage of the polyester spiral fabric when it is not in use. Exposure to harsh environmental conditions, such as extreme temperatures or direct sunlight, can degrade the fabric over time. Therefore, it is advisable to store the fabric in a cool, dry place, away from direct sunlight and other potential sources of damage. Additionally, ensuring that the fabric is clean and dry before storage can prevent the growth of mold and mildew, which can compromise its integrity.

Furthermore, training personnel on the proper handling and maintenance of polyester spiral fabric is essential. Well-informed staff can identify potential issues early and take appropriate action, thereby reducing the likelihood of costly repairs or replacements. Regular training sessions can also keep personnel updated on the latest maintenance techniques and best practices, fostering a culture of proactive maintenance within the organization.

In conclusion, the maintenance of polyester spiral fabric in sludge dewatering systems is vital for ensuring optimal performance and longevity. By implementing routine inspections, establishing cleaning schedules, monitoring operating conditions, ensuring proper storage, and training personnel, operators can significantly enhance the efficiency of their dewatering systems. These best practices not only contribute to the effective management of sludge but also promote sustainability within wastewater treatment processes, ultimately benefiting both the environment and the organization.