The Science Behind High Flow Pleated Cartridges

Benefits of Using High Flow Pleated Cartridges

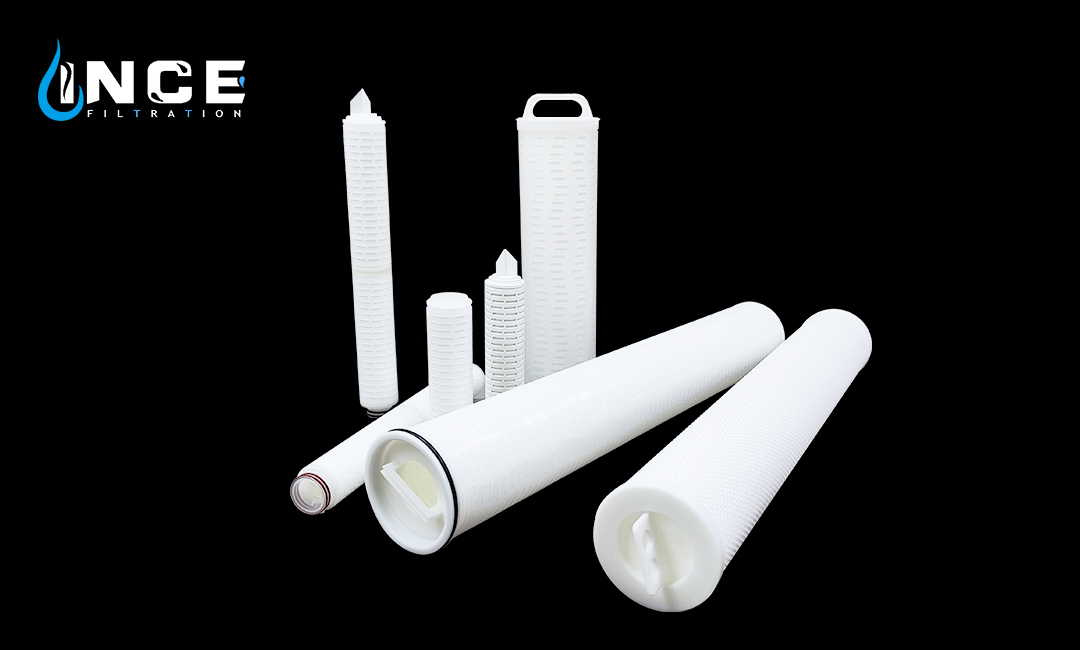

High flow pleated cartridges are an essential component in many industrial filtration systems. These cartridges are designed to handle high flow rates while maintaining efficiency in removing contaminants from liquids. The science behind high flow pleated cartridges lies in their construction and design, which allows for optimal filtration performance.

One of the key features of high flow pleated cartridges is their pleated design. The pleats increase the surface area of the filter media, allowing for greater contact with the liquid being filtered. This increased surface area results in improved filtration efficiency, as more contaminants are captured as the liquid passes through the cartridge.

In addition to their pleated design, high flow pleated cartridges are typically made from high-quality materials such as polypropylene or polyester. These materials are known for their durability and resistance to chemicals, making them ideal for use in a wide range of industrial applications. The construction of these cartridges also includes a support core, which helps to maintain the shape and integrity of the pleats during operation.

Another important aspect of the science behind high flow pleated cartridges is their flow rate capabilities. These cartridges are specifically designed to handle high flow rates, making them ideal for applications where a large volume of liquid needs to be filtered quickly and efficiently. The design of the cartridges allows for minimal pressure drop, ensuring that the flow rate is not compromised during the filtration process.

The benefits of using high flow pleated cartridges are numerous. One of the primary benefits is their high filtration efficiency. The pleated design and high-quality materials used in these cartridges result in superior contaminant removal, ensuring that the filtered liquid meets the required quality standards. This is essential in industries such as pharmaceuticals, food and beverage, and electronics manufacturing, where product quality is of utmost importance.

Another benefit of high flow pleated cartridges is their long service life. The durable construction of these cartridges allows them to withstand harsh operating conditions and frequent use without compromising their filtration performance. This results in cost savings for businesses, as the cartridges do not need to be replaced as frequently as lower-quality filters.

Furthermore, high flow pleated cartridges are easy to install and maintain. Their design allows for quick and simple replacement, minimizing downtime and ensuring that the filtration system remains operational at all times. This ease of maintenance is particularly beneficial in industries where continuous filtration is essential for production processes.

In conclusion, the science behind high flow pleated cartridges is rooted in their construction, design, and materials. These cartridges are specifically engineered to handle high flow rates while maintaining superior filtration efficiency. The benefits of using high flow pleated cartridges include high filtration efficiency, long service life, and ease of installation and maintenance. Overall, high flow pleated cartridges are an essential component in industrial filtration systems, providing reliable and efficient contaminant removal for a wide range of applications.

How High Flow Pleated Cartridges Improve Filtration Efficiency

High flow pleated cartridges are a critical component in many industrial filtration systems, providing an efficient and effective way to remove contaminants from liquids and gases. These cartridges are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for applications where large volumes of fluid need to be filtered quickly and effectively.

One of the key features of high flow pleated cartridges is their large surface area. By pleating the filter media, manufacturers are able to increase the amount of surface area available for filtration without increasing the overall size of the cartridge. This increased surface area allows for greater contact between the fluid being filtered and the filter media, resulting in more effective filtration and a higher flow rate.

In addition to their large surface area, high flow pleated cartridges are also designed to have a high dirt-holding capacity. This means that they are able to hold a significant amount of contaminants before needing to be replaced, reducing downtime and maintenance costs. The pleated design of the cartridges also helps to prevent the filter media from becoming clogged, ensuring a consistent flow rate and efficient filtration performance.

Another key factor in the efficiency of high flow pleated cartridges is the material used in their construction. The filter media is typically made from a variety of materials, including cellulose, polyester, and polypropylene, each with its own unique properties and benefits. These materials are chosen for their ability to effectively capture and retain contaminants while maintaining a high flow rate.

The pleating of the filter media also plays a crucial role in improving filtration efficiency. By pleating the filter media, manufacturers are able to create a larger surface area within a smaller space, allowing for more effective filtration without sacrificing flow rate. This design also helps to prevent the filter media from collapsing under high flow rates, ensuring consistent performance over time.

High flow pleated cartridges are also designed to be easy to install and replace, making them a convenient and cost-effective option for many industrial filtration applications. The cartridges are typically designed to fit into standard filter housings, allowing for easy integration into existing filtration systems. This ease of installation and replacement helps to minimize downtime and maintenance costs, making high flow pleated cartridges a practical choice for many industrial applications.

In conclusion, high flow pleated cartridges are a critical component in many industrial filtration systems, providing an efficient and effective way to remove contaminants from liquids and gases. Their large surface area, high dirt-holding capacity, and pleated design all contribute to their high filtration efficiency and flow rate. By choosing high flow pleated cartridges for your filtration needs, you can ensure that your system operates at peak performance and provides clean, contaminant-free fluid for your processes.

The Technology Behind High Flow Pleated Cartridges

High flow pleated cartridges are a crucial component in many industrial filtration systems. These cartridges are designed to handle high flow rates while maintaining efficiency in removing contaminants from liquids. The science behind high flow pleated cartridges lies in their construction and design, which allows for optimal filtration performance.

One key feature of high flow pleated cartridges is their pleated design. The pleats increase the surface area of the filter, allowing for more contact between the liquid and the filter media. This increased surface area results in improved filtration efficiency, as more contaminants are captured as the liquid passes through the cartridge.

In addition to the pleated design, high flow pleated cartridges are typically made from high-quality filter media. This media is carefully selected based on the specific application and the type of contaminants that need to be removed. The filter media is designed to capture particles of various sizes, ensuring that the liquid is thoroughly cleaned before it moves on to the next stage of the filtration process.

Another important aspect of high flow pleated cartridges is their construction. These cartridges are typically made from durable materials that can withstand high flow rates and pressure. The construction of the cartridges is designed to prevent bypass, ensuring that all liquid passes through the filter media for maximum filtration efficiency.

One of the key benefits of high flow pleated cartridges is their ability to handle high flow rates. These cartridges are designed to accommodate large volumes of liquid, making them ideal for industrial applications where a high flow rate is required. The high flow rate capability of these cartridges allows for faster filtration processes, reducing downtime and increasing overall efficiency.

High flow pleated cartridges are also known for their long service life. The durable construction and high-quality filter media used in these cartridges ensure that they can withstand continuous use without compromising filtration performance. This longevity makes high flow pleated cartridges a cost-effective solution for industrial filtration systems.

In conclusion, the science behind high flow pleated cartridges lies in their construction, design, and filter media. These cartridges are designed to handle high flow rates while maintaining optimal filtration efficiency. The pleated design, high-quality filter media, and durable construction of high flow pleated cartridges make them a reliable and cost-effective solution for industrial filtration systems. Whether you are looking to improve the efficiency of your filtration process or need a reliable solution for handling high flow rates, high flow pleated cartridges are a versatile option that can meet your needs.

Comparing High Flow Pleated Cartridges to Traditional Filter Options

High flow pleated cartridges are a popular choice for industrial filtration applications due to their efficiency and effectiveness in removing contaminants from liquids. These cartridges are designed to handle high flow rates while maintaining a high level of filtration performance. In this article, we will explore the science behind high flow pleated cartridges and compare them to traditional filter options.

One of the key features of high flow pleated cartridges is their large surface area. This allows for a greater volume of liquid to pass through the filter, resulting in higher flow rates. The pleated design of these cartridges also increases the amount of filtration media available, which improves the overall filtration efficiency. Traditional filter options, such as bag filters or cartridge filters, typically have a smaller surface area and may not be able to handle the same flow rates as high flow pleated cartridges.

Another advantage of high flow pleated cartridges is their ability to capture a wide range of contaminants. The pleated design creates a tortuous path for the liquid to flow through, which increases the chances of particles being trapped within the filter media. This results in a higher level of filtration efficiency compared to traditional filter options. Additionally, high flow pleated cartridges are available in a variety of micron ratings, allowing for customization based on the specific needs of the application.

In terms of maintenance, high flow pleated cartridges are also a more cost-effective option compared to traditional filters. The larger surface area and higher filtration efficiency of these cartridges mean that they can last longer before needing to be replaced. This can result in reduced downtime and lower overall operating costs for industrial facilities. Traditional filter options may require more frequent replacements, leading to increased maintenance costs over time.

When it comes to installation, high flow pleated cartridges are also easier to work with compared to traditional filter options. The pleated design allows for a simple drop-in installation, eliminating the need for additional hardware or tools. This can save time and labor during the installation process, making high flow pleated cartridges a more convenient option for industrial filtration systems.

In conclusion, high flow pleated cartridges offer a number of advantages over traditional filter options. Their large surface area, high filtration efficiency, and ease of installation make them a popular choice for industrial applications. By understanding the science behind high flow pleated cartridges and comparing them to traditional filters, it is clear that these cartridges are a superior option for handling high flow rates and capturing a wide range of contaminants. Whether you are looking to improve filtration performance, reduce maintenance costs, or simplify installation, high flow pleated cartridges are a reliable and efficient choice for industrial filtration systems.