Top Advantages of Ultipleat High Flow Filters in Industrial Use

Increased Filtration Efficiency

Ultipleat High Flow Filters have become increasingly popular in industrial applications due to their numerous advantages over traditional filtration systems. One of the key benefits of Ultipleat High Flow Filters is their increased filtration efficiency, which is crucial for maintaining the quality of products and ensuring the smooth operation of industrial processes.

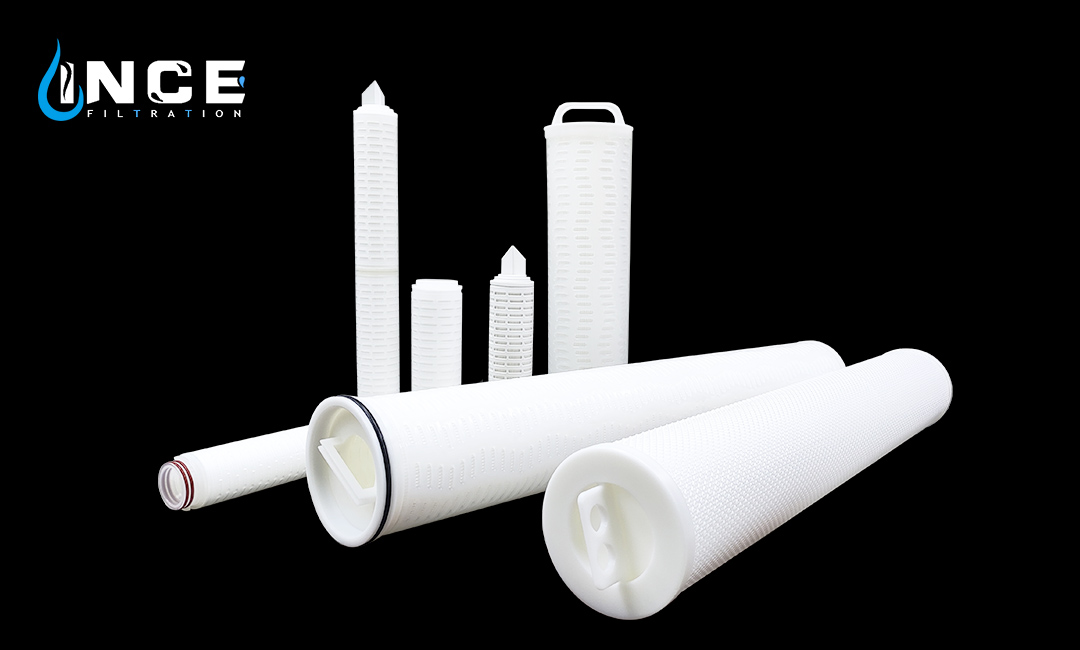

One of the main reasons why Ultipleat High Flow Filters are more efficient than traditional filters is their larger surface area. The design of these filters allows for a greater amount of filter media to be packed into a smaller space, resulting in a higher filtration capacity. This means that Ultipleat High Flow Filters can remove more contaminants from the fluid being filtered, leading to cleaner and purer end products.

In addition to their larger surface area, Ultipleat High Flow Filters also have a higher flow rate compared to traditional filters. This means that they can process a larger volume of fluid in a shorter amount of time, making them ideal for high-flow applications where speed is of the essence. The increased flow rate of Ultipleat High Flow Filters not only improves productivity but also reduces downtime, as less time is spent waiting for the filtration process to be completed.

Another advantage of Ultipleat High Flow Filters is their longer service life. Traditional filters often need to be replaced frequently, which can be costly and time-consuming. Ultipleat High Flow Filters, on the other hand, have a longer lifespan due to their durable construction and efficient design. This means that maintenance costs are reduced, and production can continue uninterrupted for longer periods of time.

Furthermore, Ultipleat High Flow Filters are designed to be easy to install and replace, making them a convenient option for industrial applications. Their modular design allows for quick and simple installation, and replacement cartridges can be easily swapped out when needed. This minimizes downtime and ensures that the filtration system is always operating at peak efficiency.

Ultipleat High Flow Filters are also highly versatile and can be customized to meet the specific needs of different industries. Whether filtering water, chemicals, or oil, these filters can be tailored to remove specific contaminants and achieve the desired level of purity. This flexibility makes Ultipleat High Flow Filters a valuable asset in a wide range of industrial settings.

In conclusion, Ultipleat High Flow Filters offer a range of advantages that make them a superior choice for industrial filtration applications. From increased filtration efficiency and flow rate to longer service life and ease of installation, these filters are designed to optimize performance and productivity. With their versatility and customizable options, Ultipleat High Flow Filters are a reliable and cost-effective solution for maintaining the quality of products and processes in various industries.

Cost Savings

Ultipleat High Flow Filters have become increasingly popular in industrial applications due to their numerous advantages. One of the key benefits of Ultipleat High Flow Filters is their cost-saving potential. These filters are designed to handle high flow rates, which means they can process more fluid in a shorter amount of time compared to traditional filters. This increased efficiency can result in significant cost savings for industrial operations.

By using Ultipleat High Flow Filters, companies can reduce the number of filters needed for their processes. Because these filters can handle higher flow rates, fewer filters are required to achieve the same level of filtration. This not only reduces the initial cost of purchasing filters but also lowers ongoing maintenance and replacement costs. In addition, the reduced number of filters means less time and labor are needed for filter changes, further contributing to cost savings.

Another cost-saving advantage of Ultipleat High Flow Filters is their longer lifespan. These filters are designed to withstand high flow rates and high levels of contamination, resulting in a longer operational life compared to traditional filters. This means that companies can go longer between filter changes, reducing downtime and maintenance costs. Additionally, the longer lifespan of Ultipleat High Flow Filters means fewer filters need to be purchased over time, further reducing costs for industrial operations.

In addition to cost savings related to filter replacement and maintenance, Ultipleat High Flow Filters can also help reduce energy costs. These filters have a lower pressure drop compared to traditional filters, meaning less energy is required to push fluid through the filtration system. This can result in lower energy consumption and reduced operating costs for industrial processes. By using Ultipleat High Flow Filters, companies can achieve cost savings not only in filter replacement and maintenance but also in energy usage.

Furthermore, Ultipleat High Flow Filters offer cost savings through their improved filtration efficiency. These filters are designed to provide high levels of filtration, capturing more contaminants and particles from the fluid being processed. This can result in cleaner fluid output, reducing the risk of equipment damage and downtime. By using Ultipleat High Flow Filters, companies can avoid costly repairs and replacements caused by contaminated fluid, ultimately saving money in the long run.

Overall, Ultipleat High Flow Filters offer a range of cost-saving advantages for industrial applications. From reducing the number of filters needed to lowering maintenance and energy costs, these filters can help companies achieve significant savings. By investing in Ultipleat High Flow Filters, industrial operations can improve efficiency, reduce downtime, and ultimately increase their bottom line. With their long lifespan, improved filtration efficiency, and lower energy consumption, Ultipleat High Flow Filters are a cost-effective solution for industrial filtration needs.

Reduced Maintenance

Ultipleat High Flow Filters have become increasingly popular in industrial applications due to their numerous advantages. One of the key benefits of Ultipleat High Flow Filters is their ability to reduce maintenance requirements, making them a cost-effective and efficient choice for industrial use.

One of the main reasons why Ultipleat High Flow Filters require less maintenance is their high dirt-holding capacity. These filters are designed to capture a large volume of contaminants without clogging, which means they can operate for longer periods without needing to be replaced or cleaned. This not only reduces the frequency of filter changes but also minimizes downtime and maintenance costs.

Additionally, Ultipleat High Flow Filters are designed to withstand high flow rates, which means they can handle a larger volume of fluid without compromising filtration efficiency. This is particularly beneficial in industrial settings where large quantities of liquid need to be filtered quickly and efficiently. By using Ultipleat High Flow Filters, industrial facilities can maintain optimal filtration performance without the need for frequent filter replacements or maintenance.

Another advantage of Ultipleat High Flow Filters is their compact design. These filters have a smaller footprint compared to traditional filtration systems, which means they can be easily integrated into existing industrial processes without requiring significant modifications. This not only saves space but also simplifies installation and maintenance, making Ultipleat High Flow Filters a convenient and practical choice for industrial applications.

Furthermore, Ultipleat High Flow Filters are designed for easy maintenance. The filters can be quickly and easily replaced without the need for specialized tools or equipment, which reduces downtime and labor costs. This makes Ultipleat High Flow Filters a user-friendly option for industrial facilities looking to streamline their maintenance processes and improve operational efficiency.

In addition to reducing maintenance requirements, Ultipleat High Flow Filters also offer superior filtration performance. These filters are designed to remove a wide range of contaminants, including particles, debris, and microorganisms, ensuring that the filtered fluid meets the required quality standards. By using Ultipleat High Flow Filters, industrial facilities can achieve consistent and reliable filtration results, which is essential for maintaining product quality and process efficiency.

Overall, Ultipleat High Flow Filters offer a range of advantages for industrial use, including reduced maintenance requirements, high dirt-holding capacity, compact design, and superior filtration performance. By choosing Ultipleat High Flow Filters, industrial facilities can benefit from cost-effective and efficient filtration solutions that help optimize operational performance and ensure product quality. Whether used in water treatment, chemical processing, food and beverage production, or other industrial applications, Ultipleat High Flow Filters are a reliable and effective choice for meeting filtration needs.

Improved Process Performance

Ultipleat High Flow Filters have become increasingly popular in industrial applications due to their numerous advantages over traditional filtration systems. These filters are designed to handle high flow rates while maintaining excellent filtration efficiency, making them ideal for a wide range of industrial processes. In this article, we will explore some of the top advantages of Ultipleat High Flow Filters in industrial use.

One of the key advantages of Ultipleat High Flow Filters is their ability to handle high flow rates without sacrificing filtration efficiency. These filters are designed to provide a large filtration area in a compact design, allowing them to process high volumes of fluid while still capturing a high percentage of contaminants. This makes Ultipleat High Flow Filters ideal for applications where a high flow rate is required, such as in the oil and gas industry or in water treatment plants.

Another advantage of Ultipleat High Flow Filters is their long service life. These filters are constructed from durable materials that are designed to withstand the rigors of industrial use. This means that Ultipleat High Flow Filters can last longer between replacements, reducing downtime and maintenance costs. In addition, the design of these filters allows for easy replacement, further reducing the time and effort required to maintain them.

Ultipleat High Flow Filters also offer superior filtration performance compared to traditional filtration systems. These filters are designed to capture a wide range of contaminants, including particles, bacteria, and other impurities. This ensures that the fluid being filtered meets the required quality standards, leading to improved process performance and product quality. In addition, Ultipleat High Flow Filters can be customized to meet specific filtration requirements, making them versatile and adaptable to a wide range of industrial applications.

One of the key advantages of Ultipleat High Flow Filters is their cost-effectiveness. While these filters may have a higher initial cost compared to traditional filtration systems, their long service life and superior filtration performance make them a cost-effective choice in the long run. By reducing downtime, maintenance costs, and the need for frequent filter replacements, Ultipleat High Flow Filters can help industrial plants save money and improve their overall efficiency.

In conclusion, Ultipleat High Flow Filters offer a range of advantages that make them an ideal choice for industrial applications. From their ability to handle high flow rates to their long service life and superior filtration performance, these filters provide a cost-effective and efficient solution for a wide range of industries. By investing in Ultipleat High Flow Filters, industrial plants can improve their process performance, reduce maintenance costs, and ensure the quality of their products.