Top Applications for Polyester Spiral Press Fabric in Industry

Textile Manufacturing: Enhancing Durability and Performance

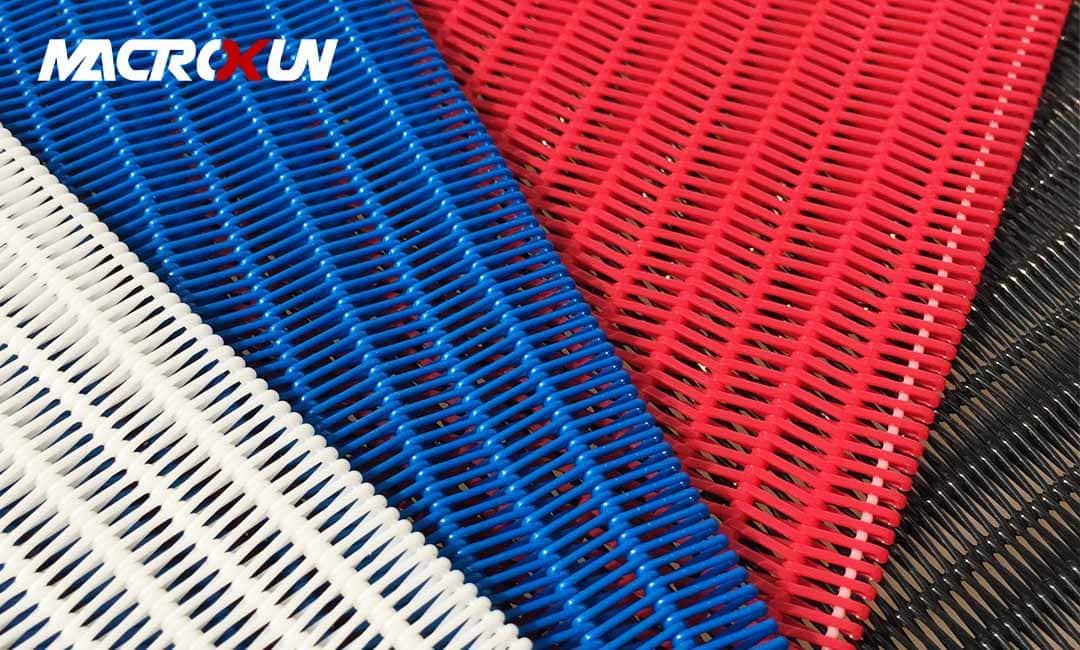

Polyester spiral press fabric is a versatile material that has found a wide range of applications in various industries, particularly in textile manufacturing. This fabric is known for its durability, strength, and resistance to wear and tear, making it an ideal choice for use in demanding industrial environments. In this article, we will explore some of the top applications for polyester spiral press fabric in the textile manufacturing industry.

One of the key applications of polyester spiral press fabric in textile manufacturing is in the production of paper. This fabric is commonly used in paper machines to help dewater the paper pulp and form the paper sheet. The spiral design of the fabric allows for efficient drainage of water from the pulp, resulting in faster drying times and improved paper quality. Additionally, the high tensile strength of polyester spiral press fabric ensures that it can withstand the rigorous conditions of paper manufacturing without tearing or breaking.

Another important application of polyester spiral press fabric in textile manufacturing is in the production of nonwoven fabrics. Nonwoven fabrics are made by bonding fibers together using various methods, such as needle punching or thermal bonding. Polyester spiral press fabric is often used as a base material in the production of nonwoven fabrics, providing a stable and durable surface for the bonding process. The smooth surface of the fabric also helps to ensure uniform bonding of the fibers, resulting in high-quality nonwoven fabrics.

In addition to paper and nonwoven fabrics, polyester spiral press fabric is also used in the production of textiles such as filter cloths and conveyor belts. Filter cloths are used in a variety of industrial processes to separate solids from liquids or gases. Polyester spiral press fabric is an ideal material for filter cloths due to its high porosity, which allows for efficient filtration of particles while maintaining good flow rates. The fabric is also resistant to chemicals and abrasion, making it suitable for use in harsh industrial environments.

Conveyor belts are another important application of polyester spiral press fabric in textile manufacturing. Conveyor belts are used to transport materials within a manufacturing facility or between different processing stages. Polyester spiral press fabric is commonly used as the belt material in conveyor systems due to its high strength and flexibility. The fabric can withstand heavy loads and high temperatures, making it a reliable choice for industrial conveyor applications.

Overall, polyester spiral press fabric plays a crucial role in enhancing the durability and performance of textile manufacturing processes. Its strength, resistance to wear and tear, and versatility make it an ideal material for a wide range of applications in the industry. Whether used in paper machines, nonwoven fabric production, filter cloths, or conveyor belts, polyester spiral press fabric helps to improve efficiency, quality, and reliability in textile manufacturing. As the industry continues to evolve and demand for high-performance materials grows, polyester spiral press fabric will undoubtedly remain a key component in the production of textiles around the world.

Filtration Systems: Improving Efficiency and Longevity

Polyester spiral press fabric has emerged as a vital component in various industrial filtration systems, significantly enhancing both efficiency and longevity. This innovative material, characterized by its unique spiral design, offers numerous advantages that make it an ideal choice for diverse applications. The filtration process is critical in many industries, including food and beverage, pharmaceuticals, and wastewater treatment, where the quality of the final product is paramount. By utilizing polyester spiral press fabric, companies can achieve superior filtration performance, leading to improved operational outcomes.

One of the primary benefits of polyester spiral press fabric is its exceptional strength and durability. The fabric is engineered to withstand high pressures and harsh chemical environments, which are common in industrial filtration processes. This resilience not only extends the lifespan of the fabric but also reduces the frequency of replacements, thereby lowering operational costs. As a result, industries can maintain consistent production levels without the interruptions that often accompany fabric failures. Furthermore, the robust nature of polyester spiral press fabric ensures that it can handle varying flow rates, making it versatile for different filtration needs.

In addition to its durability, polyester spiral press fabric is designed to provide excellent filtration efficiency. The unique spiral structure allows for a larger surface area, which enhances the fabric’s ability to capture particles and contaminants effectively. This increased surface area facilitates better flow dynamics, ensuring that the filtration process is both rapid and thorough. As industries strive for higher purity levels in their products, the use of polyester spiral press fabric becomes increasingly advantageous. The ability to achieve finer filtration without compromising flow rates is a significant factor that sets this material apart from traditional filtration fabrics.

Moreover, the maintenance of filtration systems utilizing polyester spiral press fabric is notably simplified. The fabric is easy to clean, which is essential in industries where hygiene and cleanliness are critical. Regular maintenance not only prolongs the life of the fabric but also ensures that the filtration system operates at peak efficiency. This ease of maintenance translates into reduced downtime and labor costs, allowing companies to focus on their core operations rather than on extensive cleaning procedures. Consequently, the integration of polyester spiral press fabric into filtration systems can lead to significant operational efficiencies.

Another important aspect to consider is the environmental impact of using polyester spiral press fabric in filtration systems. As industries become more conscious of their ecological footprint, the choice of materials plays a crucial role in sustainability efforts. Polyester is a recyclable material, and its use in filtration applications can contribute to a more sustainable manufacturing process. By opting for fabrics that can be reused or recycled, companies can minimize waste and promote a circular economy. This commitment to sustainability not only enhances a company’s reputation but also aligns with the growing consumer demand for environmentally responsible practices.

In conclusion, the application of polyester spiral press fabric in filtration systems represents a significant advancement in industrial filtration technology. Its strength, durability, and efficiency make it an ideal choice for various industries seeking to improve their filtration processes. The ease of maintenance and the potential for sustainability further enhance its appeal, making it a preferred option for companies aiming to optimize their operations. As industries continue to evolve and face new challenges, the role of innovative materials like polyester spiral press fabric will undoubtedly become increasingly important in driving efficiency and longevity in filtration systems.

Packaging Solutions: Sustainable and Cost-Effective Options

Polyester spiral press fabric is a versatile material that has found a wide range of applications in various industries. Its unique properties make it an ideal choice for packaging solutions, offering both sustainability and cost-effectiveness. In this article, we will explore some of the top applications of polyester spiral press fabric in industry.

One of the key advantages of polyester spiral press fabric is its high tensile strength, which makes it an excellent choice for packaging materials that need to withstand heavy loads. This strength allows the fabric to be used in applications such as bulk bags, which are commonly used in the transportation and storage of goods. The fabric’s durability ensures that the bags can safely contain and protect their contents, reducing the risk of damage during transit.

Another important application of polyester spiral press fabric is in the production of filter belts for industrial filtration systems. The fabric’s smooth surface and high permeability make it an ideal choice for filtering liquids and solids in a wide range of industries, including food and beverage, pharmaceuticals, and wastewater treatment. The fabric’s ability to withstand high temperatures and harsh chemicals makes it a reliable and long-lasting solution for filtration applications.

In the paper industry, polyester spiral press fabric is commonly used in the production of paper machine clothing. The fabric’s high strength and abrasion resistance make it an ideal choice for forming, pressing, and drying paper on the paper machine. Its smooth surface ensures uniform paper quality, while its durability allows for long-term use in demanding papermaking environments.

Polyester spiral press fabric is also used in the production of conveyor belts for a variety of industrial applications. The fabric’s flexibility and high tensile strength make it an ideal choice for conveying materials in industries such as mining, agriculture, and manufacturing. Its resistance to abrasion and chemicals ensures that the conveyor belts can withstand the rigors of daily use, reducing maintenance costs and downtime.

In the automotive industry, polyester spiral press fabric is used in the production of airbags. The fabric’s high strength and tear resistance make it an ideal choice for protecting passengers in the event of a collision. Its ability to withstand high temperatures and rapid inflation ensures that the airbags can deploy quickly and safely, reducing the risk of injury in an accident.

Overall, polyester spiral press fabric offers a wide range of applications in industry, providing sustainable and cost-effective solutions for packaging materials, filtration systems, paper machine clothing, conveyor belts, and airbags. Its unique properties make it an ideal choice for industries looking for durable, reliable, and high-performance materials. Whether used in bulk bags, filter belts, conveyor belts, or airbags, polyester spiral press fabric continues to be a versatile and valuable material in various industrial applications.