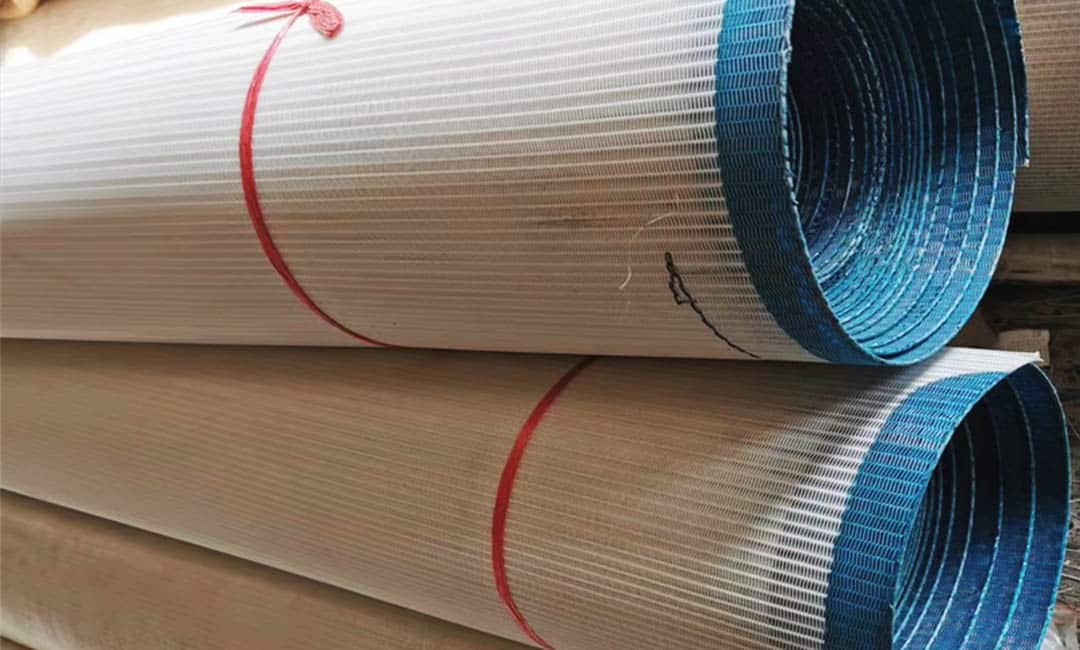

Top Applications of Polyester Spiral Filter Belts in Industry

Food Processing and Packaging

Polyester spiral filter belts have emerged as a vital component in the food processing and packaging industry, offering a range of benefits that enhance efficiency and product quality. These belts are designed to facilitate the filtration and separation processes, which are crucial in various stages of food production. One of the primary applications of polyester spiral filter belts is in the filtration of liquids, such as juices, oils, and dairy products. The unique spiral design allows for optimal flow rates while maintaining a high level of filtration efficiency. This is particularly important in the juice industry, where the removal of pulp and other solids is essential to achieve a clear, appealing product. By utilizing polyester spiral filter belts, manufacturers can ensure that their juices meet consumer expectations for clarity and taste.

In addition to liquid filtration, polyester spiral filter belts are also widely used in the drying processes of food products. For instance, in the production of snacks, such as potato chips or fruit leathers, these belts facilitate the efficient removal of moisture. The porous nature of the polyester material allows for even airflow, which is critical in achieving uniform drying. This not only enhances the texture and shelf life of the final product but also reduces energy consumption during the drying process. Consequently, food manufacturers can achieve significant cost savings while maintaining high-quality standards.

Moreover, the versatility of polyester spiral filter belts extends to their application in the packaging of food products. In modern packaging lines, these belts are employed in various stages, including the sorting, conveying, and packaging of items. Their lightweight yet durable construction allows for smooth operation, minimizing the risk of product damage during transit. Additionally, the belts can be customized to fit specific machinery, ensuring compatibility and efficiency in the packaging process. This adaptability is particularly beneficial in high-speed production environments, where downtime can lead to substantial financial losses.

Furthermore, the hygienic properties of polyester spiral filter belts make them an ideal choice for the food industry. These belts are resistant to bacteria and other contaminants, which is crucial in maintaining food safety standards. The ability to easily clean and sanitize the belts further enhances their appeal, as it ensures compliance with stringent health regulations. As food safety continues to be a top priority for manufacturers, the use of polyester spiral filter belts can significantly contribute to maintaining a safe production environment.

In addition to their functional advantages, polyester spiral filter belts also offer economic benefits. Their durability and resistance to wear and tear result in longer service life compared to traditional materials. This longevity translates into reduced replacement costs and less frequent maintenance, allowing food processors to allocate resources more effectively. As the industry continues to evolve, the demand for efficient and cost-effective solutions will only increase, making polyester spiral filter belts an indispensable asset in food processing and packaging.

In conclusion, the applications of polyester spiral filter belts in the food processing and packaging industry are extensive and varied. From enhancing filtration processes to improving drying efficiency and ensuring hygienic standards, these belts play a crucial role in optimizing production. As manufacturers strive to meet consumer demands for quality and safety, the integration of polyester spiral filter belts into their operations will undoubtedly continue to grow, solidifying their position as a key component in modern food processing technology.

Water Treatment and Filtration

Polyester spiral filter belts have emerged as a vital component in various industrial applications, particularly in the realm of water treatment and filtration. These belts, known for their durability and efficiency, play a crucial role in ensuring the purity and quality of water, which is essential for both environmental sustainability and public health. As industries increasingly prioritize eco-friendly practices, the demand for effective filtration solutions has surged, positioning polyester spiral filter belts as a preferred choice.

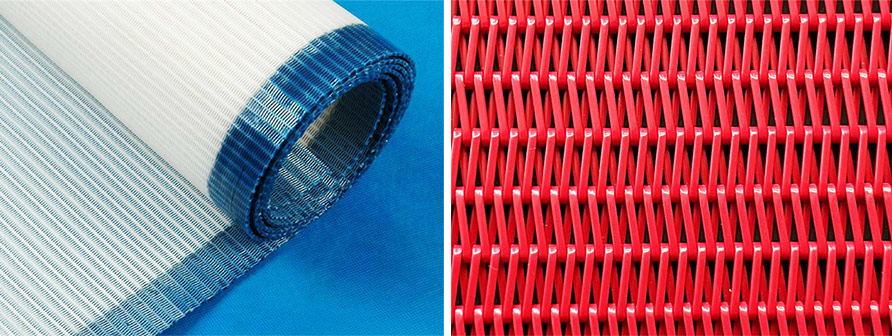

One of the primary applications of polyester spiral filter belts in water treatment is in the filtration of wastewater. In municipal and industrial settings, wastewater must undergo rigorous treatment processes to remove contaminants before it can be safely discharged or reused. Polyester spiral filter belts facilitate this process by providing a reliable medium for separating solids from liquids. Their unique spiral design allows for optimal flow rates and uniform distribution of materials, ensuring that even the finest particles are effectively captured. This capability not only enhances the efficiency of the filtration process but also contributes to the overall reduction of pollutants entering natural water bodies.

Moreover, the versatility of polyester spiral filter belts extends to various filtration methods, including gravity filtration and pressure filtration. In gravity filtration systems, these belts can be employed to create a continuous filtration surface, allowing for the gradual removal of suspended solids as water flows through. This method is particularly advantageous in applications where large volumes of water need to be treated, as it minimizes the need for extensive mechanical systems and reduces operational costs. Conversely, in pressure filtration applications, polyester spiral filter belts can withstand high pressures, making them suitable for more demanding environments where rapid filtration is required. This adaptability ensures that industries can select the most appropriate filtration method based on their specific needs.

In addition to their mechanical properties, polyester spiral filter belts are also favored for their chemical resistance. Water treatment processes often involve the use of various chemicals, including coagulants and flocculants, which can be harsh on filtration media. The inherent resistance of polyester to chemical degradation ensures that these belts maintain their structural integrity and performance over time, thereby reducing the frequency of replacements and associated costs. This longevity is particularly beneficial in large-scale operations where downtime can lead to significant financial losses.

Furthermore, the ease of maintenance associated with polyester spiral filter belts cannot be overlooked. Regular cleaning and maintenance are essential to ensure optimal performance and longevity of filtration systems. The smooth surface of these belts allows for straightforward cleaning processes, which can be conducted without the need for extensive disassembly. This feature not only saves time but also enhances the overall efficiency of water treatment operations.

As industries continue to evolve and adapt to stricter environmental regulations, the role of polyester spiral filter belts in water treatment and filtration will likely expand. Their ability to provide effective, reliable, and sustainable filtration solutions positions them as a cornerstone in the quest for cleaner water. In conclusion, the applications of polyester spiral filter belts in water treatment are diverse and impactful, contributing significantly to the enhancement of water quality and the protection of natural resources. As technology advances and the demand for efficient filtration solutions grows, these belts will undoubtedly remain at the forefront of industrial water treatment practices.

Mining and Mineral Processing

Polyester spiral filter belts have emerged as a vital component in various industrial applications, particularly in the mining and mineral processing sectors. These belts are engineered to provide efficient filtration and separation processes, which are crucial in the extraction and processing of minerals. The unique properties of polyester, including its strength, durability, and resistance to chemicals, make it an ideal material for filter belts used in harsh mining environments.

In the mining industry, the extraction of minerals often involves the use of water to separate valuable materials from waste. This process generates a significant amount of slurry, which consists of water mixed with fine particles of ore and other materials. Polyester spiral filter belts are employed in various filtration systems to dewater this slurry effectively. By utilizing these belts, mining operations can achieve higher levels of solid-liquid separation, resulting in a drier cake of minerals that is easier to handle and transport. This not only enhances the efficiency of the mining process but also reduces the environmental impact by minimizing water usage and waste generation.

Moreover, the design of polyester spiral filter belts allows for a high degree of customization, enabling them to be tailored to specific applications within the mining sector. For instance, the mesh size and belt thickness can be adjusted to accommodate different types of materials and varying levels of filtration requirements. This versatility ensures that mining companies can optimize their processes according to the unique characteristics of the minerals they are extracting. Additionally, the spiral design of these belts promotes even distribution of the slurry across the filtration surface, which further enhances the efficiency of the separation process.

Another significant advantage of polyester spiral filter belts is their resistance to wear and tear. In the mining industry, equipment is often subjected to abrasive materials and harsh operating conditions. The robust nature of polyester ensures that these filter belts can withstand such challenges, leading to longer service life and reduced maintenance costs. This durability is particularly important in mineral processing, where downtime can result in substantial financial losses. By investing in high-quality polyester spiral filter belts, mining companies can ensure continuous operation and improve their overall productivity.

Furthermore, the chemical resistance of polyester makes these filter belts suitable for use in various mineral processing applications, including the treatment of acidic or alkaline slurries. This characteristic is essential, as many minerals require specific chemical treatments during processing. The ability of polyester spiral filter belts to maintain their integrity in the presence of aggressive chemicals ensures that they can be relied upon in diverse processing environments.

In conclusion, the applications of polyester spiral filter belts in the mining and mineral processing industries are extensive and impactful. Their ability to enhance solid-liquid separation, coupled with their durability and chemical resistance, positions them as a critical component in modern mining operations. As the demand for minerals continues to grow, the role of these innovative filter belts will likely expand, driving further advancements in filtration technology and contributing to more sustainable mining practices. By leveraging the benefits of polyester spiral filter belts, mining companies can not only improve their operational efficiency but also align with environmental standards, ultimately fostering a more responsible approach to mineral extraction and processing.