Top Benefits of Using High Flow Pleated Filter Cartridges in Manufacturing

Improved Filtration Efficiency

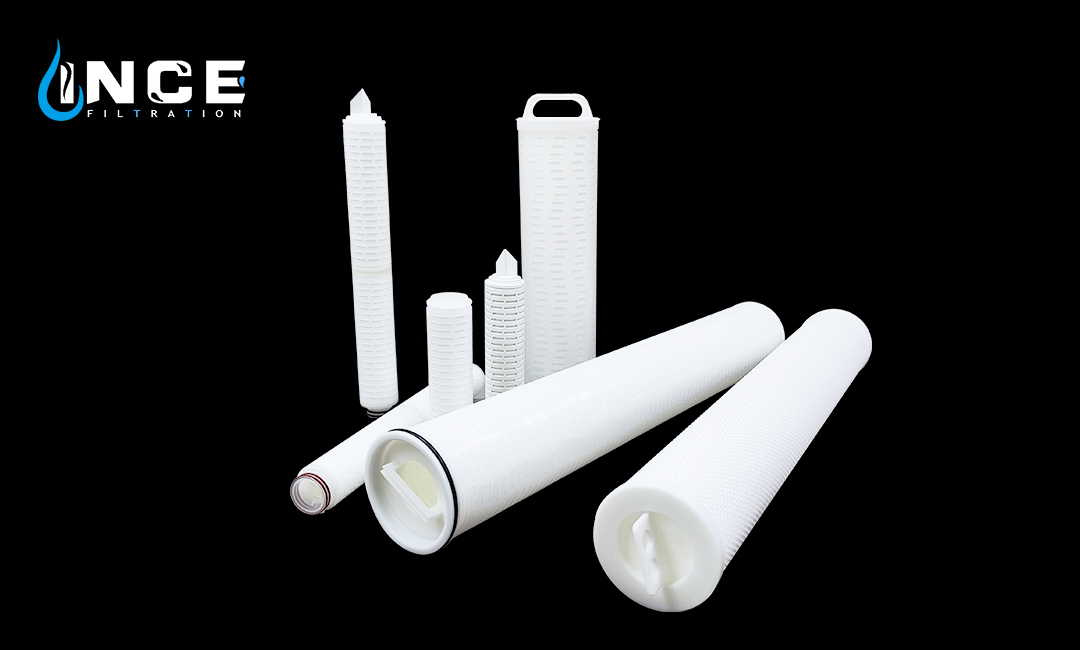

High flow pleated filter cartridges are an essential component in manufacturing processes, providing numerous benefits that contribute to improved filtration efficiency. These filter cartridges are designed to handle high flow rates while maintaining a high level of filtration performance, making them ideal for a wide range of applications in the manufacturing industry.

One of the key benefits of using high flow pleated filter cartridges is their ability to effectively remove contaminants from the process fluid. The pleated design of these cartridges provides a large surface area for filtration, allowing for greater contact between the fluid and the filter media. This results in more efficient removal of particles, debris, and other impurities, ensuring that the final product meets the required quality standards.

In addition to their superior filtration performance, high flow pleated filter cartridges also offer a longer service life compared to traditional filter cartridges. The pleated design helps to distribute the flow of fluid evenly across the filter media, preventing premature clogging and extending the lifespan of the cartridge. This not only reduces maintenance costs but also minimizes downtime for filter replacement, allowing manufacturing processes to run smoothly and efficiently.

Furthermore, high flow pleated filter cartridges are easy to install and replace, making them a convenient and cost-effective filtration solution for manufacturing facilities. The cartridges can be quickly and easily swapped out when needed, minimizing downtime and ensuring that production schedules are not disrupted. This ease of maintenance also helps to reduce labor costs and improve overall operational efficiency.

Another advantage of using high flow pleated filter cartridges is their compatibility with a wide range of fluids and operating conditions. These cartridges are available in various materials and configurations to suit different applications, from water and chemicals to oils and gases. Whether the manufacturing process requires fine filtration or coarse filtration, high flow pleated filter cartridges can be customized to meet specific requirements and deliver optimal performance.

Moreover, high flow pleated filter cartridges are designed to withstand high pressures and temperatures, making them suitable for demanding manufacturing environments. The durable construction of these cartridges ensures that they can effectively filter fluids under extreme conditions without compromising performance or integrity. This reliability and durability make high flow pleated filter cartridges a trusted choice for critical filtration applications in the manufacturing industry.

In conclusion, the benefits of using high flow pleated filter cartridges in manufacturing are clear. From improved filtration efficiency and longer service life to easy maintenance and compatibility with various fluids, these cartridges offer a cost-effective and reliable solution for meeting filtration requirements in industrial processes. By investing in high flow pleated filter cartridges, manufacturers can enhance the quality of their products, reduce maintenance costs, and optimize operational efficiency.

Extended Equipment Lifespan

High flow pleated filter cartridges are an essential component in manufacturing processes, providing numerous benefits that can improve efficiency and productivity. One of the key advantages of using these filter cartridges is the extended lifespan they offer to equipment. By effectively removing contaminants from the fluid stream, high flow pleated filter cartridges help prevent damage to sensitive equipment components, ultimately prolonging their operational lifespan.

When contaminants such as dirt, debris, and other particles are allowed to circulate through manufacturing equipment, they can cause significant wear and tear over time. This can lead to increased maintenance costs, downtime, and ultimately, the need for premature equipment replacement. By using high flow pleated filter cartridges, manufacturers can effectively capture and remove these contaminants before they have a chance to cause damage, thereby extending the lifespan of their equipment.

In addition to preventing damage to equipment, high flow pleated filter cartridges also help maintain optimal performance levels. When contaminants are allowed to build up within equipment, they can restrict flow rates, reduce efficiency, and compromise product quality. By using high flow pleated filter cartridges to remove these contaminants, manufacturers can ensure that their equipment operates at peak performance levels, delivering consistent results and minimizing the risk of costly production errors.

Furthermore, the extended lifespan of equipment resulting from the use of high flow pleated filter cartridges can lead to significant cost savings for manufacturers. By reducing the frequency of equipment repairs and replacements, manufacturers can lower their overall maintenance costs and improve their bottom line. Additionally, by maintaining optimal performance levels, manufacturers can increase their production output and efficiency, further enhancing their profitability.

Another benefit of using high flow pleated filter cartridges in manufacturing is the improved safety they provide. Contaminants in the fluid stream can pose a serious risk to both equipment and personnel, potentially leading to accidents, injuries, and even environmental hazards. By effectively removing these contaminants, high flow pleated filter cartridges help create a safer working environment for employees and reduce the risk of costly accidents and liabilities.

Overall, the extended lifespan of equipment resulting from the use of high flow pleated filter cartridges in manufacturing offers numerous benefits, including cost savings, improved performance, and enhanced safety. By investing in high-quality filter cartridges and incorporating them into their processes, manufacturers can protect their equipment, optimize their operations, and ultimately, achieve greater success in today’s competitive marketplace.

Cost Savings

High flow pleated filter cartridges are an essential component in manufacturing processes, providing numerous benefits that can ultimately lead to cost savings for businesses. These filter cartridges are designed to handle high flow rates while maintaining efficiency in removing contaminants from liquids. In this article, we will explore the top benefits of using high flow pleated filter cartridges in manufacturing.

One of the primary benefits of using high flow pleated filter cartridges is their extended service life. These cartridges have a larger surface area compared to traditional filter cartridges, allowing them to capture more contaminants before needing to be replaced. This extended service life not only reduces the frequency of cartridge changes but also minimizes downtime for maintenance, ultimately saving businesses time and money.

Additionally, high flow pleated filter cartridges offer superior filtration efficiency. The pleated design of these cartridges provides a larger filtration area, allowing for more effective removal of particles and contaminants from liquids. This increased efficiency results in cleaner end products and improved overall product quality, which can lead to cost savings by reducing the need for rework or product recalls.

Another benefit of using high flow pleated filter cartridges is their compatibility with a wide range of liquids and applications. These cartridges are available in various materials and micron ratings, making them suitable for filtering different types of liquids, including water, chemicals, oils, and more. Their versatility allows businesses to use a single type of filter cartridge for multiple applications, simplifying inventory management and reducing costs associated with stocking multiple types of cartridges.

Furthermore, high flow pleated filter cartridges are designed for high flow rates, making them ideal for manufacturing processes that require fast and efficient filtration. These cartridges can handle higher flow rates compared to traditional filter cartridges, allowing businesses to increase production speeds without compromising on filtration quality. This increased throughput can result in higher productivity and cost savings by reducing processing times and improving overall efficiency.

In addition to their cost-saving benefits, high flow pleated filter cartridges also offer easy installation and maintenance. These cartridges are designed for quick and simple replacement, minimizing downtime for maintenance and reducing labor costs associated with filter changes. Their user-friendly design allows for easy handling and installation, making them a convenient and cost-effective filtration solution for manufacturing facilities.

Overall, the top benefits of using high flow pleated filter cartridges in manufacturing include extended service life, superior filtration efficiency, compatibility with a wide range of liquids, high flow rates, and easy installation and maintenance. By incorporating these cartridges into their processes, businesses can achieve cost savings through reduced downtime, improved product quality, increased productivity, and simplified inventory management. High flow pleated filter cartridges are a valuable investment for manufacturing facilities looking to optimize their filtration processes and improve overall efficiency.

Enhanced Product Quality

High flow pleated filter cartridges are an essential component in manufacturing processes, providing numerous benefits that ultimately lead to enhanced product quality. These filter cartridges are designed to handle high flow rates while effectively removing contaminants from liquids, ensuring that the final product meets the highest standards of quality and purity.

One of the key benefits of using high flow pleated filter cartridges is their superior filtration efficiency. These cartridges are constructed with a large surface area and pleated design, allowing for maximum contact between the filter media and the liquid being filtered. This results in a more thorough removal of contaminants, such as particles, debris, and microorganisms, which can compromise the quality of the final product.

In addition to their high filtration efficiency, high flow pleated filter cartridges also offer a longer service life compared to traditional filter cartridges. The pleated design of these cartridges allows for a greater dirt-holding capacity, meaning they can effectively capture and retain more contaminants before needing to be replaced. This not only reduces downtime for maintenance but also helps to lower overall operating costs for manufacturing facilities.

Furthermore, high flow pleated filter cartridges are designed to withstand high flow rates without sacrificing filtration performance. This is crucial in manufacturing processes where a continuous and uninterrupted flow of liquid is required. By using high flow pleated filter cartridges, manufacturers can ensure that their production processes run smoothly and efficiently, without any disruptions caused by clogged or inefficient filters.

Another benefit of using high flow pleated filter cartridges is their versatility and compatibility with a wide range of liquids and applications. These cartridges are available in various sizes, micron ratings, and materials, allowing manufacturers to choose the right filter cartridge for their specific needs. Whether filtering water, chemicals, oils, or other liquids, high flow pleated filter cartridges can provide the necessary filtration to maintain product quality.

Moreover, high flow pleated filter cartridges are easy to install and replace, making them a convenient and cost-effective filtration solution for manufacturing facilities. With quick and simple installation procedures, these cartridges can be easily integrated into existing filtration systems, minimizing downtime and maximizing productivity. Additionally, their replaceable design allows for easy maintenance and ensures that the filtration system remains efficient and effective over time.

Overall, the use of high flow pleated filter cartridges in manufacturing processes offers numerous benefits that contribute to enhanced product quality. From superior filtration efficiency and longer service life to compatibility with various liquids and easy installation, these filter cartridges provide a reliable and cost-effective solution for maintaining the purity and integrity of the final product. By incorporating high flow pleated filter cartridges into their filtration systems, manufacturers can ensure that their products meet the highest standards of quality and consistency.