Troubleshooting Common Issues with High Flow Filter Cartridges

How to Identify and Fix Leaks in High Flow Filter Cartridges

Troubleshooting Common Issues with High Flow Filter Cartridges

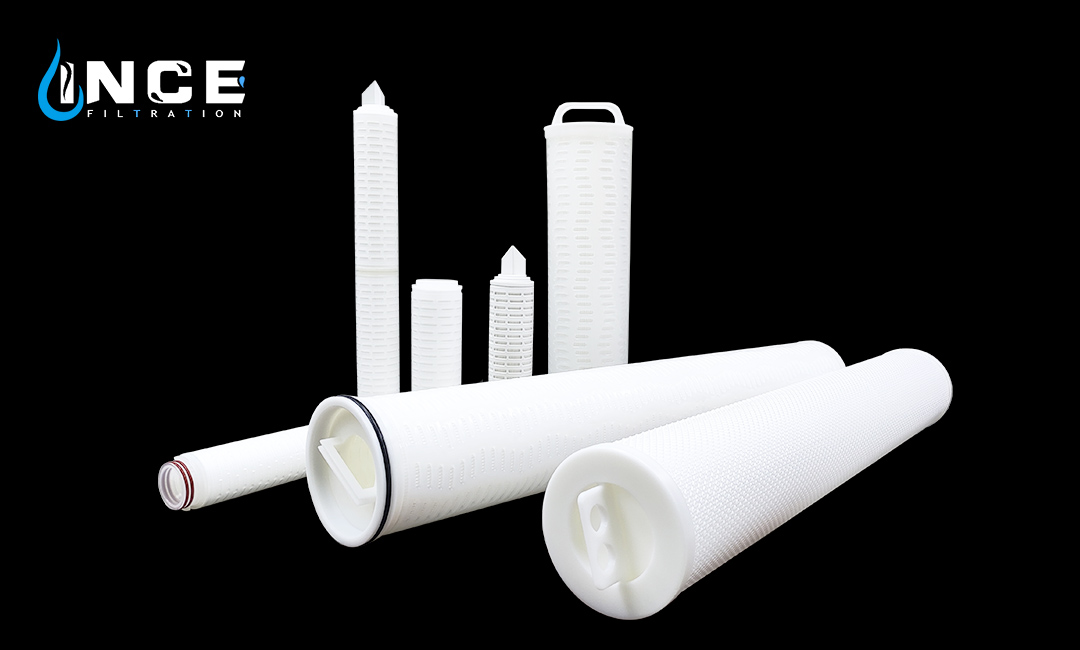

High flow filter cartridges are an essential component of many industrial filtration systems. They are designed to handle large volumes of fluid and remove contaminants effectively. However, like any mechanical device, they can experience issues that need to be addressed. In this article, we will discuss how to identify and fix leaks in high flow filter cartridges, one of the most common problems encountered.

Firstly, it is important to understand that leaks in high flow filter cartridges can occur for various reasons. One common cause is a damaged or worn-out O-ring. The O-ring is a crucial component that creates a seal between the cartridge and the filter housing. Over time, it can become brittle or deformed, leading to leaks. To identify if the O-ring is the culprit, carefully inspect it for any signs of damage or wear. If you notice any cracks or deformities, it is time to replace it.

Another possible cause of leaks is a loose or improperly tightened cartridge. When installing a high flow filter cartridge, it is crucial to ensure that it is securely tightened in the filter housing. If it is not tightened enough, it can result in leaks. On the other hand, overtightening can also cause issues, such as damaging the O-ring or distorting the cartridge. To fix this problem, carefully remove the cartridge and reinstall it, making sure to follow the manufacturer’s guidelines for proper tightening.

In some cases, leaks can occur due to a faulty gasket. The gasket is another component that helps create a seal between the cartridge and the housing. If the gasket is damaged or worn out, it can lead to leaks. To check if the gasket is the issue, inspect it for any signs of wear or damage. If necessary, replace the gasket with a new one to ensure a proper seal.

Additionally, leaks can also be caused by a cracked or damaged filter housing. Over time, the housing can become weakened or develop cracks, allowing fluid to escape. To identify if the housing is the problem, carefully inspect it for any visible cracks or damage. If you notice any, it is crucial to replace the housing to prevent further leaks.

Furthermore, it is essential to consider the quality of the high flow filter cartridge itself. Low-quality cartridges may not be able to withstand the high flow rates or handle the pressure, leading to leaks. If you have ruled out all other possible causes and are still experiencing leaks, it may be worth investing in a higher quality cartridge that is specifically designed for high flow applications.

In conclusion, leaks in high flow filter cartridges can be a common issue that needs to be addressed promptly. By identifying the cause of the leak, such as a damaged O-ring, loose cartridge, faulty gasket, or cracked housing, you can take the necessary steps to fix the problem. Regular inspection and maintenance of your filtration system can help prevent leaks and ensure its optimal performance. Remember to always follow the manufacturer’s guidelines and consult with professionals if needed.

Common Causes of Reduced Flow Rate in High Flow Filter Cartridges

Troubleshooting Common Issues with High Flow Filter Cartridges

High flow filter cartridges are an essential component in many industrial processes, ensuring the removal of contaminants and impurities from liquids. However, like any other equipment, these cartridges can experience issues that affect their performance. One common problem that users encounter is a reduced flow rate. In this section, we will explore the common causes of this issue and provide troubleshooting tips to help you resolve it.

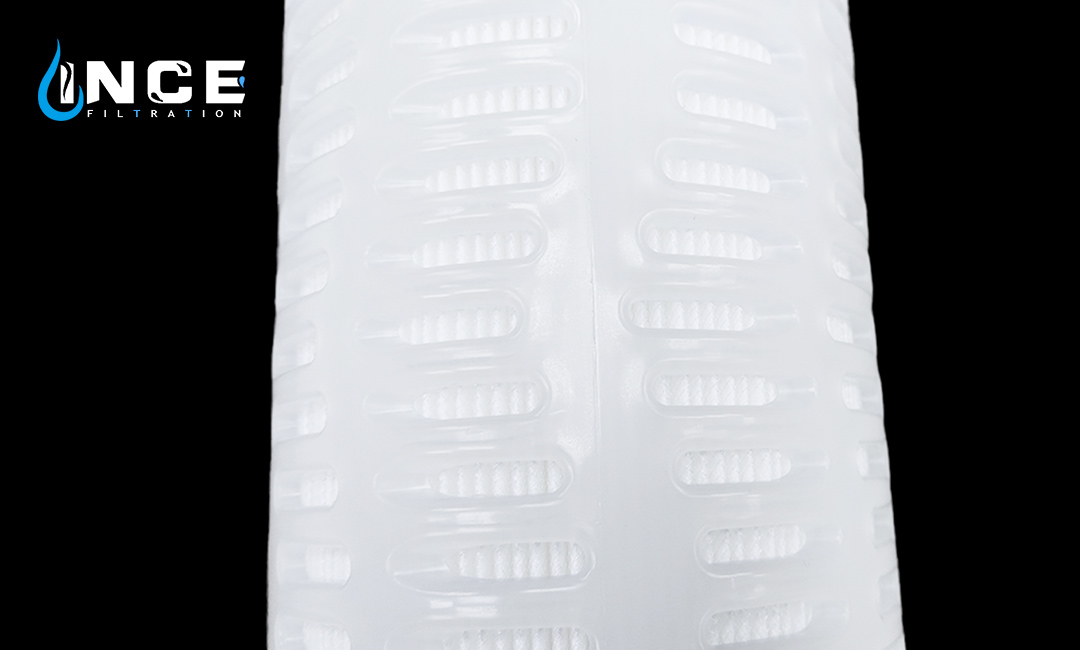

One of the primary causes of reduced flow rate in high flow filter cartridges is clogging. Over time, the cartridge can accumulate dirt, debris, and other particles, which can obstruct the flow of liquid. This is especially true in applications where the liquid being filtered contains high levels of contaminants. To troubleshoot this issue, you can start by inspecting the cartridge for visible signs of clogging. If you notice a significant buildup of debris, it may be necessary to clean or replace the cartridge.

Another potential cause of reduced flow rate is a damaged or worn-out cartridge. High flow filter cartridges are designed to withstand high pressures and flow rates, but they can still experience wear and tear over time. If the cartridge is damaged, it may not be able to effectively filter the liquid, resulting in a reduced flow rate. To troubleshoot this issue, you can visually inspect the cartridge for any signs of damage, such as cracks or tears. If you identify any damage, it is recommended to replace the cartridge to restore optimal performance.

In some cases, the reduced flow rate may be caused by improper installation or setup. High flow filter cartridges require proper alignment and connection to ensure optimal flow. If the cartridge is not installed correctly, it can lead to flow restrictions and reduced performance. To troubleshoot this issue, you can carefully review the installation instructions provided by the manufacturer and ensure that all connections are secure and aligned properly. Additionally, you can check for any leaks or loose fittings that may be affecting the flow rate.

Another potential cause of reduced flow rate is a mismatch between the cartridge and the application requirements. High flow filter cartridges come in different sizes and configurations to accommodate various flow rates and filtration needs. If the cartridge you are using is not suitable for your specific application, it may result in a reduced flow rate. To troubleshoot this issue, you can review the specifications of the cartridge and compare them to the requirements of your application. If there is a mismatch, it may be necessary to replace the cartridge with one that is better suited for your needs.

In conclusion, troubleshooting common issues with high flow filter cartridges is essential to ensure optimal performance. Reduced flow rate is a common problem that can be caused by clogging, damaged cartridges, improper installation, or a mismatch between the cartridge and the application requirements. By following the troubleshooting tips provided in this section, you can identify the cause of the issue and take appropriate steps to resolve it. Remember to consult the manufacturer’s guidelines and seek professional assistance if needed.

Troubleshooting Tips for Clogged High Flow Filter Cartridges

Troubleshooting Common Issues with High Flow Filter Cartridges

High flow filter cartridges are an essential component of many industrial filtration systems. They are designed to handle large volumes of liquid and remove contaminants effectively. However, like any other equipment, they can encounter issues that may affect their performance. In this article, we will discuss some common problems that you may encounter with high flow filter cartridges and provide troubleshooting tips to help you resolve them.

One of the most common issues with high flow filter cartridges is clogging. Over time, the cartridge can become clogged with dirt, debris, or other contaminants, reducing its flow capacity and efficiency. If you notice a decrease in flow rate or pressure, it is likely that your cartridge is clogged.

To troubleshoot this issue, the first step is to inspect the cartridge for any visible signs of clogging. Look for a buildup of dirt or debris on the surface of the cartridge. If you see any, it is time to clean or replace the cartridge.

Cleaning the cartridge is relatively simple. Start by shutting off the flow of liquid and relieving any pressure in the system. Then, remove the cartridge from its housing and rinse it thoroughly with clean water. You can use a soft brush or sponge to gently scrub away any stubborn dirt or debris. Once the cartridge is clean, reinstall it in the housing and restart the flow of liquid.

If cleaning the cartridge does not resolve the issue, it may be time to replace it. Over time, the filter media can become worn out or damaged, making it less effective at removing contaminants. In such cases, replacing the cartridge is the best solution to restore optimal performance.

Another common issue with high flow filter cartridges is leaks. Leaks can occur due to a variety of reasons, such as improper installation, damaged seals, or cracks in the housing. If you notice any leaks, it is important to address them promptly to prevent further damage to your filtration system.

To troubleshoot a leak, start by inspecting the cartridge and its housing for any visible signs of damage. Look for cracks, loose fittings, or worn-out seals. If you find any, replace the damaged parts immediately.

If there are no visible signs of damage, the leak may be due to improper installation. Check that the cartridge is properly seated in its housing and that all connections are tight and secure. If necessary, refer to the manufacturer’s instructions for proper installation procedures.

In some cases, leaks may occur due to excessive pressure in the system. High flow filter cartridges are designed to handle a specific flow rate and pressure range. If the pressure exceeds the cartridge’s capacity, it can cause leaks. In such cases, you may need to install a pressure regulator to ensure that the pressure remains within the cartridge’s limits.

In conclusion, troubleshooting common issues with high flow filter cartridges is essential to maintain the efficiency and performance of your filtration system. Clogging and leaks are two of the most common problems that you may encounter. By following the troubleshooting tips provided in this article, you can effectively address these issues and ensure that your high flow filter cartridges continue to operate at their best. Remember to clean or replace clogged cartridges and promptly address any leaks to prevent further damage to your filtration system.

Addressing Issues with High Flow Filter Cartridge Compatibility

Troubleshooting Common Issues with High Flow Filter Cartridges

High flow filter cartridges are an essential component in many industrial filtration systems. They are designed to handle large volumes of fluid and provide efficient filtration. However, like any other equipment, they can encounter issues that need to be addressed. In this article, we will discuss some common problems that can arise with high flow filter cartridges and provide troubleshooting tips to help you resolve them.

One of the most common issues with high flow filter cartridges is compatibility. These cartridges are available in various sizes and configurations, and it is crucial to ensure that the cartridge you are using is compatible with your filtration system. Incompatibility can lead to poor filtration performance, leaks, or even damage to the cartridge or the system itself.

To address compatibility issues, the first step is to carefully review the specifications of your filtration system and compare them with the cartridge you are using. Check the dimensions, flow rate, and pressure rating to ensure they match. If there is a mismatch, you may need to replace the cartridge with a compatible one.

Another common issue is the presence of contaminants in the fluid being filtered. High flow filter cartridges are designed to remove particles and impurities from the fluid, but if the fluid is heavily contaminated, it can overwhelm the cartridge and reduce its effectiveness. This can result in poor filtration performance and a shorter lifespan for the cartridge.

To troubleshoot this issue, you should first assess the level of contamination in the fluid. If it is excessive, you may need to consider pre-filtration or other methods to remove larger particles before they reach the high flow filter cartridge. Additionally, regular maintenance and cleaning of the filtration system can help prevent the buildup of contaminants and ensure optimal performance.

Clogging is another common problem with high flow filter cartridges. Over time, particles and impurities can accumulate on the surface of the cartridge, reducing its flow capacity and efficiency. This can lead to increased pressure drop, decreased flow rate, and ultimately, the need for frequent cartridge replacements.

To address clogging, regular maintenance is essential. Depending on the level of contamination in the fluid being filtered, you may need to clean or replace the cartridge more frequently. Additionally, using a pre-filter or a strainer can help remove larger particles and reduce the risk of clogging.

Leakage is yet another issue that can occur with high flow filter cartridges. Leaks can occur due to improper installation, damaged seals, or cracks in the cartridge housing. Not only can leaks compromise the filtration efficiency, but they can also lead to fluid loss and potential damage to the surrounding equipment.

To troubleshoot leaks, start by inspecting the cartridge and its housing for any visible damage or signs of wear. Ensure that all connections are properly tightened and that seals are in good condition. If you identify any issues, replace the damaged parts or seek professional assistance if needed.

In conclusion, troubleshooting common issues with high flow filter cartridges requires careful assessment and attention to detail. Addressing compatibility issues, managing fluid contamination, preventing clogging, and resolving leaks are key steps to ensure optimal performance and longevity of your filtration system. Regular maintenance and adherence to manufacturer guidelines are crucial in preventing and resolving these issues. By following these troubleshooting tips, you can keep your high flow filter cartridges operating at their best and maintain the efficiency of your filtration system.