Troubleshooting Guide for Pall High Flow Filter Cartridges

Common Issues with Pall High Flow Filter Cartridges and Their Solutions

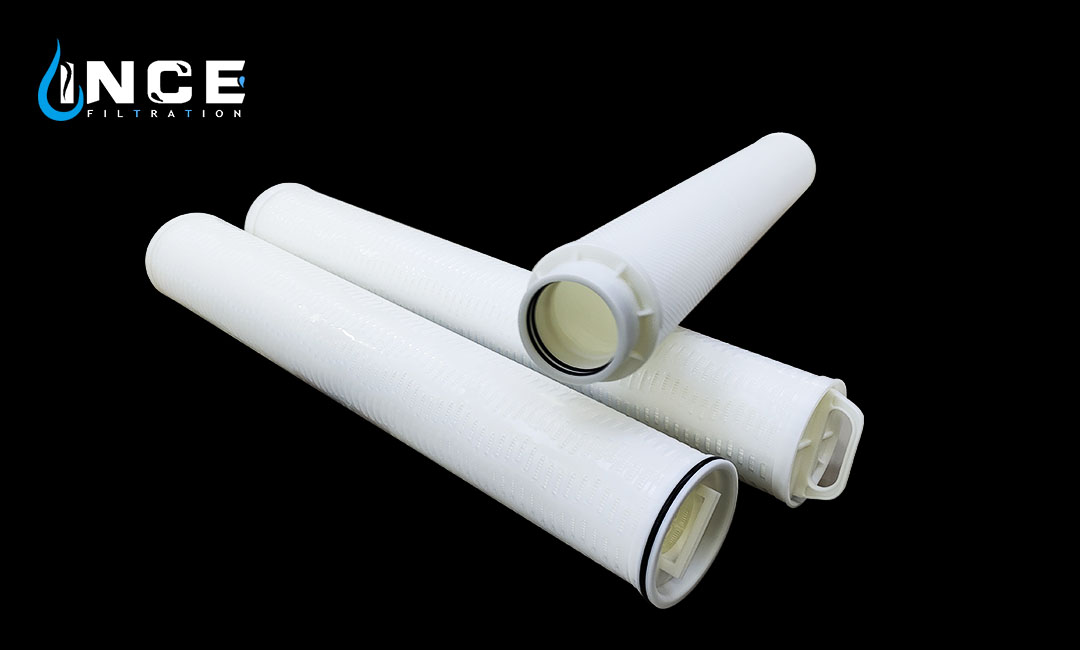

Pall high flow filter cartridges are widely used in various industries for their efficiency in removing contaminants from liquids. However, like any filtration system, they can encounter issues that may affect their performance. In this troubleshooting guide, we will discuss some common problems that users may face with Pall high flow filter cartridges and provide solutions to resolve them.

One common issue that users may encounter is a decrease in flow rate. This can be caused by a clogged filter cartridge, which restricts the flow of liquid through the system. To address this issue, users should first check the differential pressure across the filter cartridge. If the pressure is higher than normal, it indicates that the cartridge is clogged and needs to be replaced. Regular maintenance and monitoring of the filter cartridges can help prevent this issue from occurring.

Another common problem with Pall high flow filter cartridges is leakage. This can be caused by a loose connection between the cartridge and the housing, or a damaged O-ring. To fix this issue, users should check the connections and tighten them if necessary. If the O-ring is damaged, it should be replaced with a new one to ensure a proper seal. Regular inspection of the filter cartridge housing can help prevent leaks from occurring.

Users may also experience issues with the quality of the filtrate produced by the Pall high flow filter cartridges. If the filtrate appears cloudy or contains particles, it may indicate that the filter cartridge is not effectively removing contaminants. In this case, users should check the condition of the filter cartridge and replace it if necessary. It is also important to ensure that the filter cartridge is properly installed and that the system is operating at the correct pressure and flow rate to achieve optimal filtration performance.

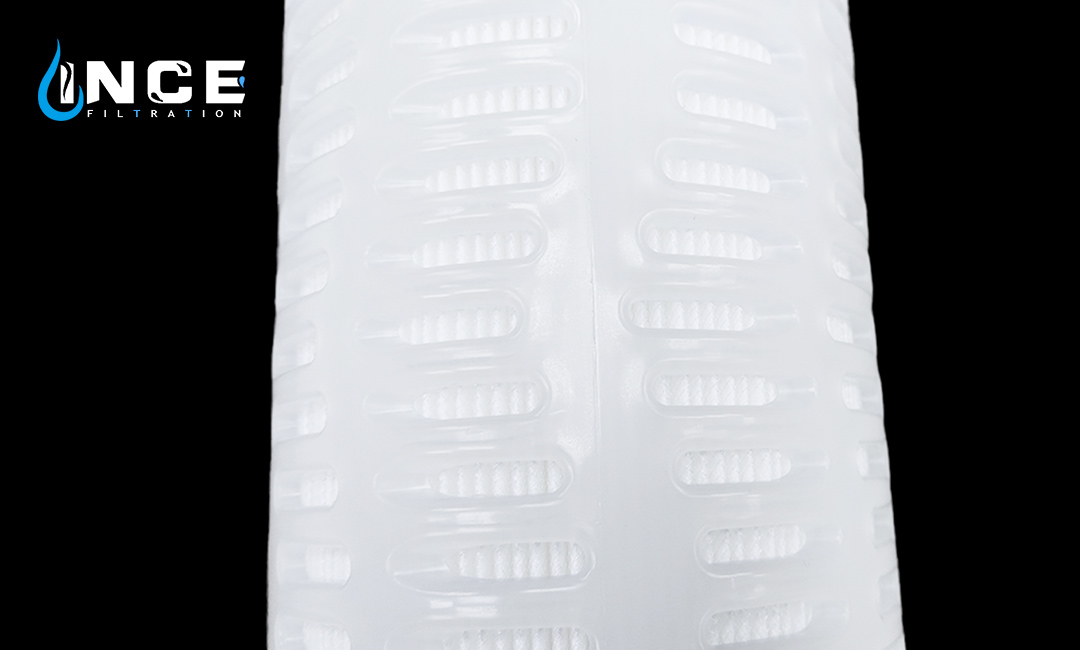

In some cases, users may encounter issues with the integrity of the filter cartridge itself, such as tears or holes in the filter media. This can result in bypass of contaminants and reduce the effectiveness of the filtration system. To address this issue, users should inspect the filter cartridge for any damage and replace it if necessary. Regular inspection of the filter cartridges can help identify potential issues before they affect the performance of the system.

Users may also face challenges with the overall performance of the Pall high flow filter cartridges, such as reduced filter life or inconsistent filtration results. These issues can be caused by improper installation, inadequate maintenance, or using the wrong type of filter cartridge for the application. To troubleshoot these issues, users should review the manufacturer’s guidelines for installation and maintenance, and ensure that the correct filter cartridge is being used for the specific application.

In conclusion, Pall high flow filter cartridges are a reliable filtration solution for various industries, but they may encounter issues that can affect their performance. By following the troubleshooting tips outlined in this guide, users can address common problems with Pall high flow filter cartridges and ensure that their filtration system operates efficiently. Regular maintenance, monitoring, and inspection of the filter cartridges are essential to prevent issues and maintain optimal filtration performance.