Ultipleat High Flow Filters: A Guide to Industrial Applications

Benefits of Using Ultipleat High Flow Filters in Industrial Processes

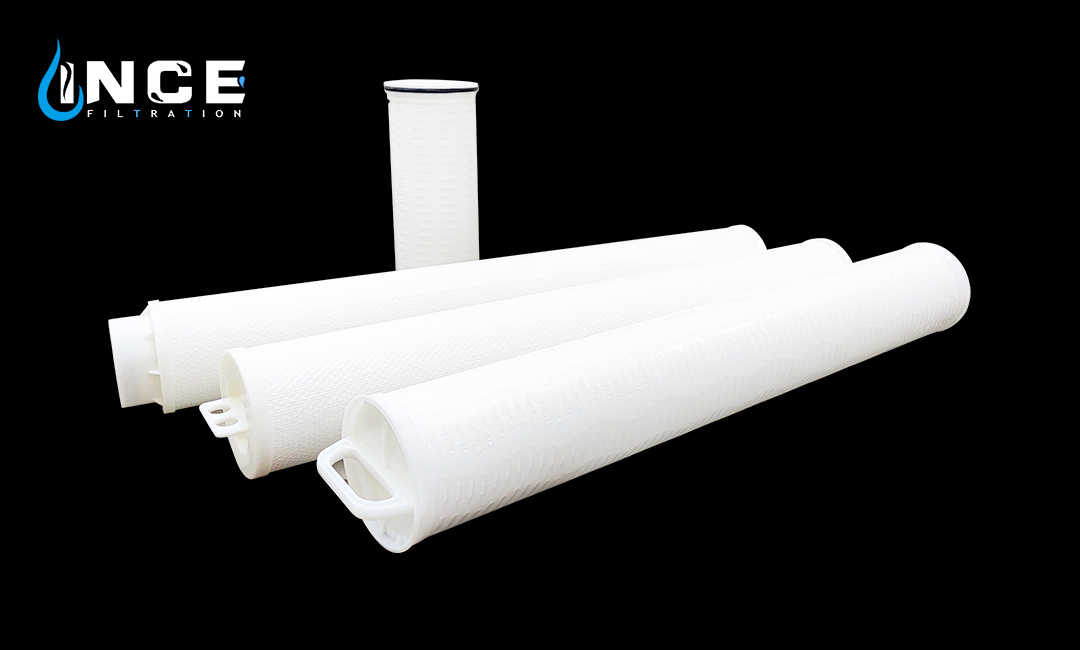

Ultipleat High Flow Filters are a crucial component in many industrial processes, providing a reliable and efficient solution for removing contaminants from liquids. These filters offer a wide range of benefits that make them a popular choice for industries such as oil and gas, chemical processing, and water treatment. In this article, we will explore the advantages of using Ultipleat High Flow Filters in industrial applications.

One of the key benefits of Ultipleat High Flow Filters is their high flow rate capabilities. These filters are designed to handle large volumes of liquid, making them ideal for applications where a high flow rate is required. This can help to improve the efficiency of industrial processes by reducing the time it takes to filter liquids, ultimately leading to cost savings and increased productivity.

In addition to their high flow rate capabilities, Ultipleat High Flow Filters also offer superior filtration performance. These filters are designed to remove a wide range of contaminants from liquids, including particles, bacteria, and other impurities. This can help to improve the quality of the final product, ensuring that it meets the required specifications and standards.

Another benefit of Ultipleat High Flow Filters is their long service life. These filters are constructed from durable materials that are designed to withstand the harsh conditions often found in industrial environments. This means that they can be used for extended periods of time without needing to be replaced, reducing maintenance costs and downtime.

Ultipleat High Flow Filters are also easy to install and maintain, making them a convenient option for industrial applications. These filters can be quickly and easily installed in existing systems, allowing for minimal disruption to operations. Additionally, they are designed to be easily cleaned and maintained, helping to prolong their service life and ensure optimal performance.

Furthermore, Ultipleat High Flow Filters are cost-effective solutions for industrial processes. These filters offer a high level of filtration performance at a competitive price point, making them a cost-effective option for businesses looking to improve their filtration processes. Additionally, their long service life and low maintenance requirements help to further reduce overall costs.

Overall, Ultipleat High Flow Filters offer a range of benefits that make them a valuable asset in industrial applications. From their high flow rate capabilities and superior filtration performance to their long service life and cost-effective nature, these filters provide a reliable and efficient solution for removing contaminants from liquids. Whether used in oil and gas, chemical processing, or water treatment, Ultipleat High Flow Filters are a versatile and effective option for businesses looking to improve their industrial processes.

How Ultipleat High Flow Filters Improve Efficiency and Productivity

Ultipleat High Flow Filters are a critical component in many industrial applications, providing a cost-effective and efficient solution for liquid filtration. These filters are designed to handle high flow rates while maintaining excellent filtration efficiency, making them ideal for a wide range of industries. In this article, we will explore how Ultipleat High Flow Filters can improve efficiency and productivity in industrial settings.

One of the key benefits of Ultipleat High Flow Filters is their ability to handle high flow rates without sacrificing filtration performance. Traditional filters often struggle to maintain efficiency at high flow rates, leading to increased maintenance and downtime. Ultipleat High Flow Filters, on the other hand, are specifically designed to handle these demanding conditions, ensuring that your filtration system operates at peak efficiency.

In addition to their high flow capabilities, Ultipleat High Flow Filters also offer superior filtration efficiency. These filters are available in a variety of micron ratings, allowing you to customize your filtration system to meet the specific needs of your application. Whether you are filtering water, chemicals, or other liquids, Ultipleat High Flow Filters can provide the level of filtration you require to ensure product quality and consistency.

Another advantage of Ultipleat High Flow Filters is their long service life. These filters are constructed from durable materials that can withstand the rigors of industrial use, reducing the frequency of filter changes and maintenance. This not only saves time and money but also helps to minimize downtime and keep your operations running smoothly.

Ultipleat High Flow Filters are also easy to install and maintain, further enhancing their efficiency and productivity benefits. These filters are designed for quick and simple installation, allowing you to get your filtration system up and running in no time. Additionally, their low maintenance requirements mean that you can spend less time on filter changes and more time on other important tasks.

In conclusion, Ultipleat High Flow Filters are a valuable asset for industrial applications looking to improve efficiency and productivity. With their high flow capabilities, superior filtration efficiency, long service life, and ease of installation and maintenance, these filters offer a cost-effective and reliable solution for liquid filtration. Whether you are filtering water, chemicals, or other liquids, Ultipleat High Flow Filters can help you achieve optimal results in your industrial processes.

Case Studies Highlighting Successful Implementation of Ultipleat High Flow Filters

Ultipleat High Flow Filters have become a popular choice for industrial applications due to their efficiency and effectiveness in removing contaminants from various fluids. In this article, we will explore some case studies that showcase the successful implementation of Ultipleat High Flow Filters in different industries.

One such case study comes from a manufacturing plant that produces automotive parts. The plant was facing issues with their hydraulic systems due to contamination in the fluid, which was causing frequent breakdowns and maintenance issues. After consulting with a filtration expert, they decided to install Ultipleat High Flow Filters in their hydraulic systems.

The results were immediate and impressive. The filters were able to remove contaminants efficiently, resulting in a significant reduction in breakdowns and maintenance costs. The plant saw an increase in productivity and a decrease in downtime, ultimately leading to cost savings and improved efficiency.

Another case study comes from a food processing plant that was experiencing issues with their water filtration system. The plant was using traditional filters that were not able to handle the high flow rates required for their operations. This was causing clogs and inefficiencies in the system.

After switching to Ultipleat High Flow Filters, the plant saw a dramatic improvement in their water filtration system. The filters were able to handle the high flow rates with ease, resulting in a more efficient and reliable system. The plant was able to increase production and reduce waste, ultimately leading to cost savings and improved quality control.

In the pharmaceutical industry, a company was facing challenges with their process water filtration system. The existing filters were not able to meet the stringent requirements for purity and quality. After consulting with a filtration expert, the company decided to switch to Ultipleat High Flow Filters.

The results were outstanding. The filters were able to remove even the smallest contaminants from the process water, ensuring that it met the strict quality standards required for pharmaceutical production. The company saw an improvement in product quality and consistency, ultimately leading to increased customer satisfaction and regulatory compliance.

Overall, these case studies highlight the versatility and effectiveness of Ultipleat High Flow Filters in a variety of industrial applications. Whether it’s in manufacturing, food processing, or pharmaceuticals, these filters have proven to be a reliable and cost-effective solution for removing contaminants and improving system efficiency.

In conclusion, Ultipleat High Flow Filters are a valuable tool for industrial applications where efficient filtration is essential. These case studies demonstrate the positive impact that these filters can have on productivity, cost savings, and overall system performance. By choosing Ultipleat High Flow Filters, companies can ensure that their operations run smoothly and efficiently, leading to improved quality control and customer satisfaction.

Maintenance Tips for Ultipleat High Flow Filters to Prolong Lifespan and Performance

Ultipleat High Flow Filters are a crucial component in many industrial applications, providing efficient filtration of liquids to ensure the smooth operation of equipment and machinery. These filters are designed to handle high flow rates and remove contaminants effectively, making them a popular choice for industries such as oil and gas, chemical processing, and water treatment.

To ensure the longevity and optimal performance of Ultipleat High Flow Filters, proper maintenance is essential. Regular maintenance not only prolongs the lifespan of the filters but also ensures that they continue to operate at peak efficiency. In this article, we will discuss some key maintenance tips for Ultipleat High Flow Filters that can help you get the most out of your investment.

One of the most important maintenance tasks for Ultipleat High Flow Filters is regular cleaning. Over time, contaminants can build up on the filter media, reducing its effectiveness and potentially causing damage to the filter itself. To prevent this, it is recommended to clean the filters at regular intervals, following the manufacturer’s guidelines for the specific model you are using.

When cleaning Ultipleat High Flow Filters, it is important to use the right cleaning agents and techniques to avoid damaging the filter media. Typically, a mild detergent or specialized filter cleaning solution is recommended for cleaning the filters. Avoid using harsh chemicals or abrasive materials, as these can cause irreparable damage to the filter media.

In addition to regular cleaning, it is also important to inspect Ultipleat High Flow Filters for any signs of wear or damage. Check the filter housing for leaks or cracks, and inspect the filter media for tears or clogs. If any issues are found, it is important to address them promptly to prevent further damage to the filter and ensure continued performance.

Another important maintenance tip for Ultipleat High Flow Filters is to replace the filter media at regular intervals. Over time, the filter media can become saturated with contaminants and lose its effectiveness. By replacing the filter media according to the manufacturer’s recommendations, you can ensure that the filters continue to operate at peak efficiency and provide reliable filtration.

When replacing the filter media, be sure to use high-quality replacement media that is compatible with your specific Ultipleat High Flow Filter model. Using the wrong type of filter media can compromise the performance of the filter and potentially cause damage to your equipment.

In conclusion, proper maintenance is essential for prolonging the lifespan and performance of Ultipleat High Flow Filters. By following these maintenance tips, you can ensure that your filters continue to operate at peak efficiency and provide reliable filtration for your industrial applications. Regular cleaning, inspection, and replacement of filter media are key components of a comprehensive maintenance plan for Ultipleat High Flow Filters. By investing time and effort into maintaining your filters, you can protect your equipment, reduce downtime, and ensure the smooth operation of your industrial processes.