Understanding Rosin Bags Micron Ratings – A Complete Guide

Importance of Understanding Rosin Bags Micron Ratings

When it comes to making rosin, the micron rating of your rosin bags plays a crucial role in determining the quality of the final product. The micron rating refers to the size of the mesh used in the rosin bag, which directly impacts the yield and quality of the rosin extract.

By understanding the micron ratings of rosin bags, you can make informed decisions on which bags to use for different types of material. Lower micron ratings are ideal for finer materials like kief or bubble hash, while higher micron ratings work better for larger flower buds.

Choosing the right micron rating can help you maximize your rosin yield, preserve terpenes and cannabinoids, and achieve the desired consistency of the final product. Therefore, having a comprehensive guide to rosin bags’ micron ratings is essential for both beginners and experienced rosin enthusiasts.

Factors to Consider When Selecting Rosin Bags

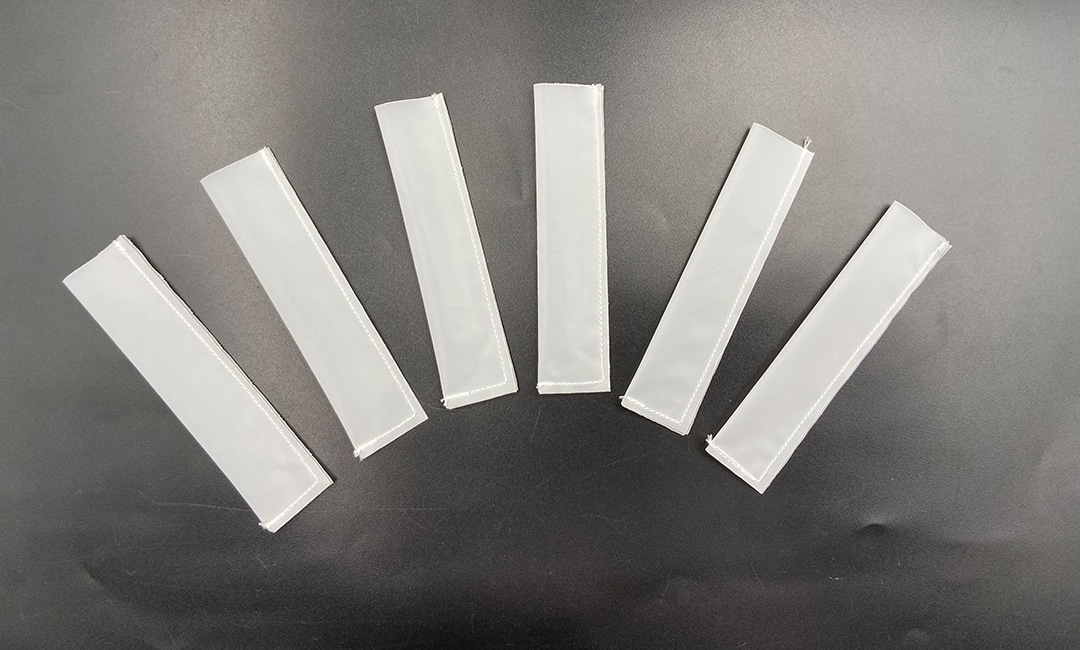

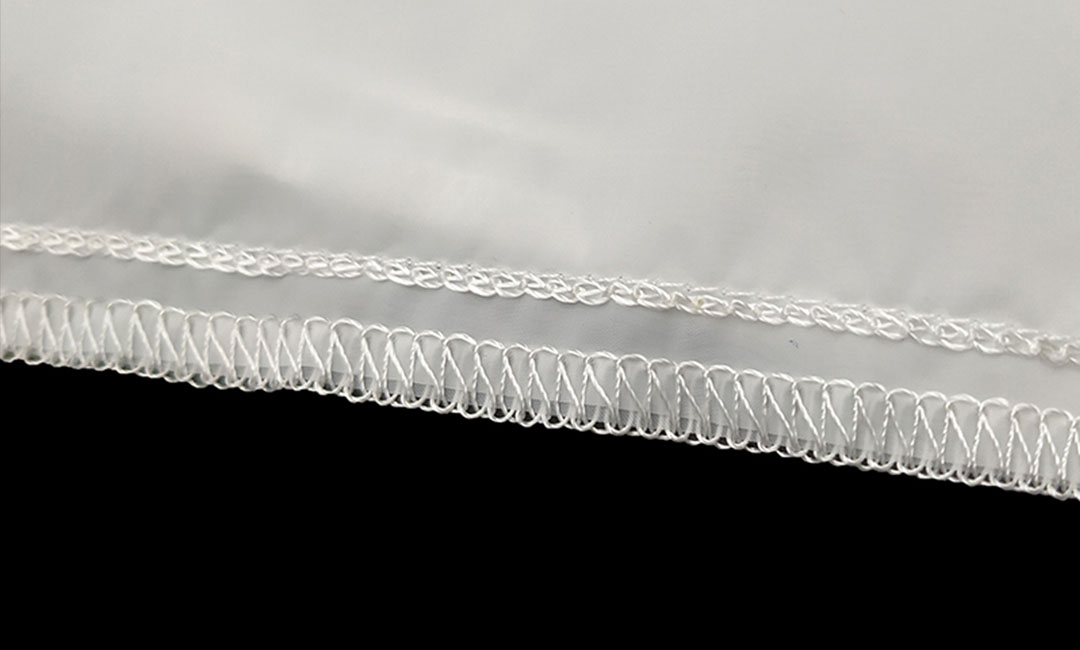

When selecting rosin bags, there are several factors to consider beyond just the micron rating. The material of the bag, the seam quality, and the size of the bag all play a role in the extraction process and overall yield.

High-quality rosin bags are typically made from food-grade nylon, which is heat resistant and durable. Additionally, well-constructed seams prevent blowouts during the pressing process, ensuring that your material stays contained within the bag.

Size is another important factor to consider when choosing rosin bags. The size of the bag should match the amount of material you are pressing to optimize the extraction process. Using the right size bag can help you achieve better yields and consistent results with each press.

Tips for Maximizing Rosin Extraction Efficiency

To maximize rosin extraction efficiency, it is essential to follow some key tips and best practices. First and foremost, ensure that your rosin bags are clean and free from any contaminants that could affect the quality of the extract.

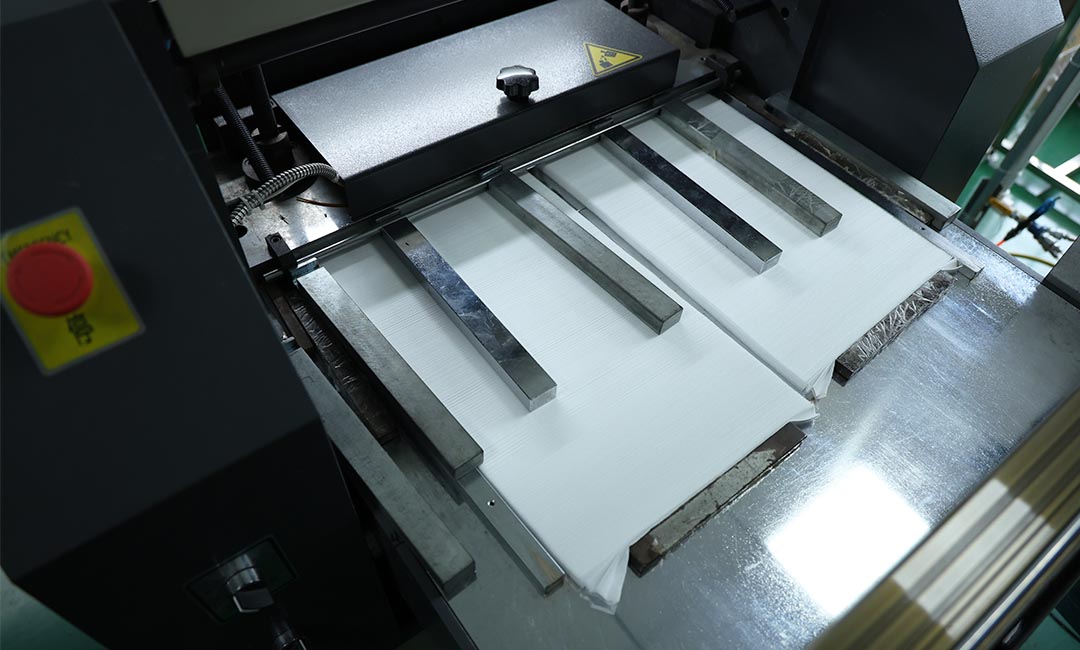

Properly prepping your material by grinding or breaking it down to the right consistency can also improve extraction efficiency. Additionally, applying the right amount of pressure and heat during the pressing process is crucial for optimal rosin yield.

Experimenting with different micron ratings, temperatures, and pressing times can help you fine-tune your extraction process and achieve the desired results. Keeping detailed records of your pressing parameters and results can also aid in identifying trends and making adjustments for future presses.