Understanding the Design of High Flow Pleated Filter Cartridges

Benefits of Using High Flow Pleated Filter Cartridges

High flow pleated filter cartridges are an essential component in many industrial processes, providing efficient filtration of liquids and gases. These cartridges are designed to handle high flow rates while maintaining a high level of filtration efficiency. Understanding the design of high flow pleated filter cartridges is crucial for maximizing their benefits in various applications.

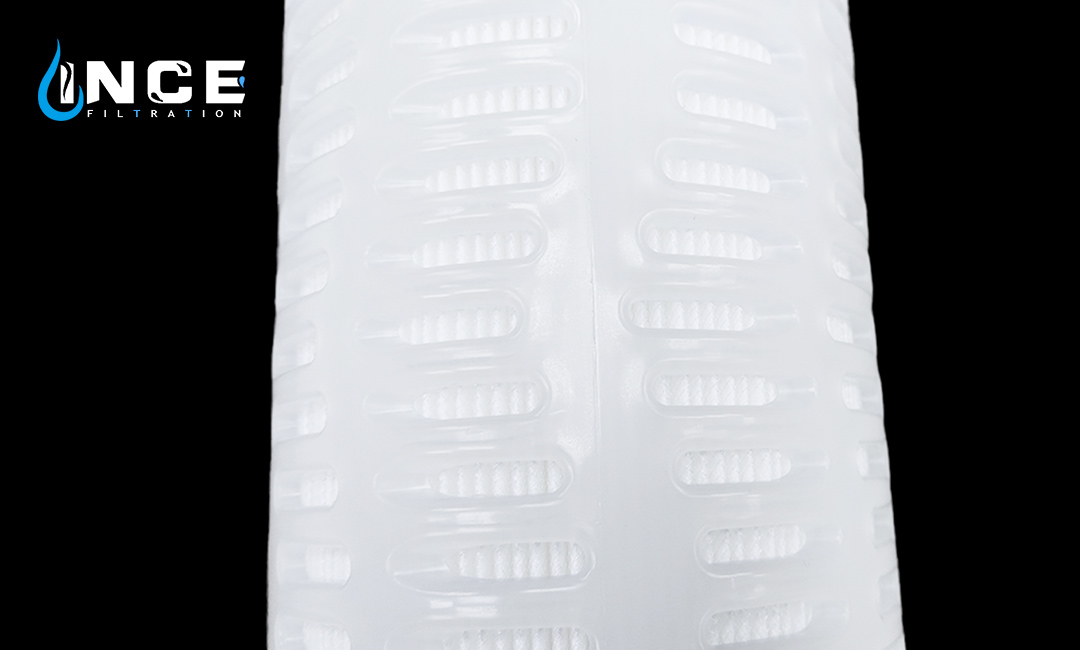

One of the key features of high flow pleated filter cartridges is their large surface area. The pleated design of these cartridges allows for a greater filtration area compared to traditional filter cartridges. This increased surface area enables the cartridges to handle higher flow rates without sacrificing filtration efficiency. As a result, high flow pleated filter cartridges are ideal for applications that require high flow rates and fine filtration.

In addition to their large surface area, high flow pleated filter cartridges are constructed using high-quality materials that are designed to withstand harsh operating conditions. The filter media used in these cartridges is typically made from materials such as polypropylene, polyester, or fiberglass, which are known for their durability and chemical resistance. This ensures that the cartridges can effectively filter out contaminants without being damaged by the fluid being filtered.

Furthermore, high flow pleated filter cartridges are designed with a rigid core that provides structural support and prevents the cartridges from collapsing under high flow rates. The core is typically made from materials such as polypropylene or stainless steel, which are strong and resistant to corrosion. This design feature ensures that the cartridges maintain their shape and integrity even when subjected to high pressure and flow rates.

Another important aspect of the design of high flow pleated filter cartridges is the pleating pattern. The pleats in the filter media are carefully spaced and arranged to maximize the filtration efficiency of the cartridges. This design allows for the effective capture of contaminants while minimizing pressure drop across the cartridge. As a result, high flow pleated filter cartridges can maintain a high level of filtration efficiency over an extended period of time.

The benefits of using high flow pleated filter cartridges are numerous. These cartridges offer a higher dirt-holding capacity compared to traditional filter cartridges, which means they can capture more contaminants before needing to be replaced. This results in longer service life and reduced maintenance costs for industrial processes.

Additionally, high flow pleated filter cartridges provide a more consistent flow rate and pressure drop compared to other types of filters. This ensures that the filtration system operates efficiently and effectively, leading to improved process performance and product quality. The high flow capabilities of these cartridges also allow for faster filtration rates, which can help increase productivity and reduce downtime in industrial operations.

Overall, understanding the design of high flow pleated filter cartridges is essential for maximizing their benefits in various applications. These cartridges are designed to handle high flow rates while maintaining a high level of filtration efficiency, making them ideal for industrial processes that require efficient and reliable filtration. By utilizing high flow pleated filter cartridges, industries can improve process performance, reduce maintenance costs, and ensure the quality of their products.

Key Features to Look for in High Flow Pleated Filter Cartridges

High flow pleated filter cartridges are an essential component in many industrial processes, providing efficient filtration of liquids and gases. Understanding the design of these filter cartridges is crucial for selecting the right product for your specific application. In this article, we will explore the key features to look for in high flow pleated filter cartridges to ensure optimal performance and longevity.

One of the most important aspects of high flow pleated filter cartridges is the material used in their construction. The filter media is typically made of synthetic materials such as polypropylene, polyester, or nylon, which offer excellent chemical resistance and durability. These materials are designed to capture particles of various sizes, ranging from large contaminants to submicron particles, ensuring thorough filtration of the fluid or gas passing through the cartridge.

The pleated design of the filter cartridge is another critical feature to consider. Pleating increases the surface area of the filter media, allowing for greater contact with the fluid or gas being filtered. This design maximizes the filtration efficiency and extends the lifespan of the cartridge by reducing the frequency of filter replacements. Additionally, pleated filter cartridges are more resistant to clogging, ensuring consistent flow rates and preventing pressure drops in the system.

Another important consideration when selecting high flow pleated filter cartridges is the micron rating. The micron rating indicates the size of particles that the filter can capture, with lower micron ratings indicating finer filtration. It is essential to choose a filter cartridge with the appropriate micron rating for your application to ensure effective removal of contaminants. For example, a filter cartridge with a lower micron rating may be required for applications where submicron particles need to be removed, such as in pharmaceutical or semiconductor manufacturing.

In addition to the material, design, and micron rating, the size and configuration of the filter cartridge are also key factors to consider. High flow pleated filter cartridges are available in various sizes and configurations to accommodate different flow rates and installation requirements. It is essential to select a filter cartridge that is compatible with your system and can handle the flow rate of the fluid or gas being filtered. Additionally, some filter cartridges are designed for single-use applications, while others can be cleaned and reused multiple times, providing cost savings and environmental benefits.

When choosing high flow pleated filter cartridges, it is crucial to consider the operating conditions of your system. Some filter cartridges are designed for high-temperature or high-pressure applications, while others are suitable for low-temperature or low-pressure environments. It is essential to select a filter cartridge that can withstand the specific conditions of your system to ensure optimal performance and longevity.

In conclusion, understanding the design of high flow pleated filter cartridges is essential for selecting the right product for your application. By considering the material, design, micron rating, size, configuration, and operating conditions of the filter cartridge, you can ensure efficient filtration and prolong the lifespan of your system. With the right filter cartridge in place, you can maintain the quality of your products and protect your equipment from contaminants, ensuring smooth and reliable operation.

How High Flow Pleated Filter Cartridges Improve Filtration Efficiency

High flow pleated filter cartridges are an essential component in many industrial filtration systems. These cartridges are designed to improve filtration efficiency by increasing the flow rate of liquid or gas through the filter media. Understanding the design of high flow pleated filter cartridges is crucial for ensuring optimal performance and longevity of the filtration system.

One of the key features of high flow pleated filter cartridges is their pleated design. The pleats in the filter media provide a larger surface area for filtration, allowing for greater contact between the liquid or gas being filtered and the filter media. This increased surface area results in improved filtration efficiency, as more contaminants are captured and removed from the fluid stream.

In addition to their pleated design, high flow pleated filter cartridges are typically made from high-quality materials such as polypropylene, polyester, or fiberglass. These materials are chosen for their durability, chemical resistance, and ability to capture a wide range of contaminants. The construction of the filter cartridges is also important, as it must be able to withstand high flow rates and pressure without compromising filtration performance.

Another important aspect of the design of high flow pleated filter cartridges is the spacing between the pleats. The spacing between the pleats determines the size of the particles that can be captured by the filter media. Smaller spacing between the pleats allows for finer filtration, while larger spacing allows for higher flow rates. By carefully selecting the spacing between the pleats, manufacturers can tailor the filter cartridges to meet specific filtration requirements.

High flow pleated filter cartridges are also designed to be easily replaceable, allowing for quick and efficient maintenance of the filtration system. Most filter cartridges are designed to be compatible with standard filter housings, making it easy to install and replace them as needed. This ease of maintenance helps to minimize downtime and ensure that the filtration system continues to operate at peak efficiency.

In conclusion, high flow pleated filter cartridges are an essential component in many industrial filtration systems. Their pleated design, high-quality materials, and carefully engineered construction all contribute to improved filtration efficiency. By understanding the design of high flow pleated filter cartridges, users can ensure that their filtration system operates at optimal performance and effectively removes contaminants from the fluid stream. With proper maintenance and replacement of filter cartridges as needed, industrial filtration systems can continue to provide clean and pure fluids for a wide range of applications.

Common Applications for High Flow Pleated Filter Cartridges

High flow pleated filter cartridges are a crucial component in many industrial processes, providing efficient filtration of liquids and gases. These cartridges are designed to handle high flow rates while maintaining a high level of filtration efficiency. Understanding the design of high flow pleated filter cartridges is essential for selecting the right cartridge for your specific application.

One common application for high flow pleated filter cartridges is in the water treatment industry. These cartridges are used to remove contaminants such as sediment, chlorine, and bacteria from water, ensuring that it meets the required quality standards. The high flow design of these cartridges allows for a greater volume of water to be filtered in a shorter amount of time, making them ideal for large-scale water treatment facilities.

Another common application for high flow pleated filter cartridges is in the oil and gas industry. These cartridges are used to remove impurities from hydraulic fluids, lubricants, and other process fluids, ensuring that equipment operates efficiently and reliably. The high flow design of these cartridges allows for continuous operation at high flow rates, making them ideal for demanding industrial applications.

In the pharmaceutical industry, high flow pleated filter cartridges are used to remove particles and microorganisms from process fluids, ensuring that products meet strict quality standards. The high flow design of these cartridges allows for fast and efficient filtration, reducing downtime and increasing productivity. These cartridges are also used in the food and beverage industry to remove contaminants from ingredients and finished products, ensuring that they are safe for consumption.

High flow pleated filter cartridges are also commonly used in the automotive industry to remove contaminants from coolant, oil, and other fluids used in manufacturing processes. The high flow design of these cartridges allows for efficient filtration of large volumes of fluid, ensuring that equipment operates smoothly and reliably. These cartridges are also used in the electronics industry to remove particles and impurities from process fluids, ensuring that electronic components are free from defects.

Overall, high flow pleated filter cartridges are a versatile and efficient filtration solution for a wide range of industrial applications. Their high flow design allows for fast and efficient filtration of liquids and gases, making them ideal for demanding industrial processes. By understanding the design of high flow pleated filter cartridges and their common applications, you can select the right cartridge for your specific filtration needs. Whether you are in the water treatment, oil and gas, pharmaceutical, automotive, or electronics industry, high flow pleated filter cartridges can help you achieve reliable and efficient filtration results.