Understanding the Maximum Bag Size for Different Rosin Press Plate Sizes

Benefits of Using the Correct Bag Size for Your Rosin Press Plate

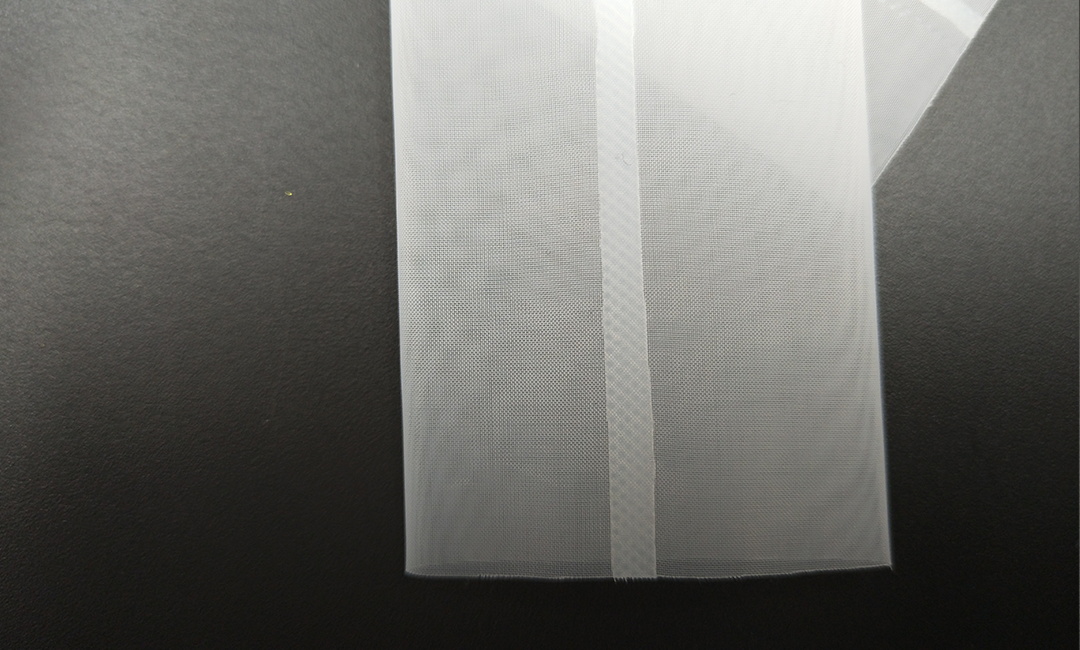

When it comes to using a rosin press for extracting cannabis concentrates, one of the key factors to consider is the size of the filter bags that you use. The filter bags play a crucial role in the extraction process, as they help to contain the material being pressed and prevent it from contaminating the rosin. Using the correct bag size for your rosin press plate is essential for achieving optimal results and maximizing the yield of your extraction.

The maximum bag size that you can use with your rosin press plate will depend on the size of the plates themselves. Larger plates will be able to accommodate larger bags, while smaller plates will require smaller bags. It is important to understand the relationship between plate size and bag size in order to ensure that you are using the correct equipment for your extraction needs.

Using a bag that is too small for your plates can result in a number of issues. The material being pressed may spill out of the bag, contaminating the rosin and reducing the overall yield of the extraction. Additionally, using a bag that is too small can put unnecessary strain on the plates and the press itself, potentially causing damage to the equipment. It is important to use a bag that is appropriately sized for your plates in order to avoid these problems.

On the other hand, using a bag that is too large for your plates can also cause issues. A bag that is too large may not be able to contain the material being pressed effectively, leading to a loss of yield and potentially contaminating the rosin. Additionally, a bag that is too large may not fit properly on the plates, resulting in uneven pressure distribution and an inconsistent extraction. It is important to use a bag that is the correct size for your plates in order to achieve the best results.

In general, it is recommended to use a bag that is slightly smaller than the size of your plates. This will ensure that the material being pressed is contained effectively and that the bag fits properly on the plates. For example, if you have 3×5 inch plates, you may want to use a 2×4 inch bag. This will allow for a small margin of error while still ensuring that the bag is appropriately sized for the plates.

Using the correct bag size for your rosin press plate has a number of benefits. It can help to maximize the yield of your extraction by ensuring that the material being pressed is contained effectively and that the pressure is distributed evenly across the plates. Using the correct bag size can also help to prevent contamination of the rosin, resulting in a higher quality final product. Additionally, using the correct bag size can help to prolong the life of your equipment by reducing strain on the plates and the press.

In conclusion, understanding the maximum bag size for different rosin press plate sizes is essential for achieving optimal results in your extraction process. Using a bag that is the correct size for your plates can help to maximize yield, prevent contamination, and prolong the life of your equipment. By taking the time to select the right bag size for your plates, you can ensure that you are getting the most out of your rosin press.

How to Determine the Maximum Bag Size for Your Specific Rosin Press Plate

When it comes to using a rosin press for extracting cannabis concentrates, one important factor to consider is the size of the filter bags that you will be using. The size of the filter bag will determine the amount of material that can be pressed at one time, as well as the overall yield and quality of the final product. In this article, we will discuss how to determine the maximum bag size for your specific rosin press plate size.

The first step in determining the maximum bag size for your rosin press plate is to measure the size of the plates themselves. Most rosin press plates come in standard sizes, such as 3×5 inches, 4×7 inches, or 5×5 inches. Once you have measured the size of your plates, you can then determine the maximum bag size that will fit comfortably on the plates without overhanging or causing any issues during the pressing process.

It is important to note that the maximum bag size for your rosin press plate will also depend on the type of material that you are pressing. For example, if you are pressing flower or trim, you may be able to use a larger bag size compared to pressing hash or kief, which may require a smaller bag size to ensure proper extraction.

In general, it is recommended to use a filter bag that is slightly smaller than the size of your rosin press plates. This will help to ensure that the material is evenly distributed across the plates during the pressing process, resulting in a more consistent and efficient extraction.

Another factor to consider when determining the maximum bag size for your rosin press plate is the amount of material that you will be pressing at one time. If you are only pressing small amounts of material, you may be able to use a smaller bag size compared to pressing larger quantities of material.

It is also important to consider the quality of the filter bags that you are using. High-quality filter bags are essential for ensuring a clean and efficient extraction process. Cheaper, lower-quality bags may tear or break during the pressing process, leading to a loss of material and a decrease in overall yield.

In conclusion, understanding the maximum bag size for your specific rosin press plate is essential for achieving optimal results when extracting cannabis concentrates. By measuring the size of your plates, considering the type of material you are pressing, and using high-quality filter bags, you can ensure a successful and efficient extraction process. Remember to always follow the manufacturer’s guidelines and recommendations when using your rosin press to achieve the best possible results.

Common Mistakes When Choosing Bag Size for Rosin Press Plate

When it comes to extracting rosin using a rosin press, one of the most critical factors to consider is the size of the bag used in conjunction with the press plate. Many users, especially those new to the process, often make common mistakes when selecting the appropriate bag size, which can significantly impact the quality and yield of the final product. Understanding these pitfalls is essential for achieving optimal results.

One prevalent mistake is underestimating the importance of matching the bag size to the press plate dimensions. Users frequently opt for bags that are either too small or too large for their specific press plate. A bag that is too small may not adequately contain the material, leading to spillage and loss of product during the pressing process. Conversely, a bag that is excessively large can result in uneven pressure distribution, which may hinder the extraction efficiency. Therefore, it is crucial to select a bag that closely aligns with the dimensions of the press plate to ensure a uniform and effective extraction.

Another common error involves neglecting the material being pressed. Different materials have varying densities and moisture contents, which can influence the choice of bag size. For instance, when pressing drier materials, a smaller bag may suffice, as the material can compact more easily. However, when dealing with denser or moister materials, a larger bag may be necessary to accommodate the expansion that occurs during the pressing process. Failing to consider these characteristics can lead to suboptimal extraction and diminished yields.

Additionally, many users overlook the significance of bag thickness. The thickness of the bag can affect both the extraction process and the quality of the rosin produced. Thicker bags may provide better filtration and prevent unwanted plant material from contaminating the final product. However, if the bag is too thick for the material being pressed, it may impede the flow of rosin, resulting in lower yields. Therefore, it is essential to strike a balance between bag thickness and the specific requirements of the material being processed.

Moreover, some individuals mistakenly believe that using multiple bags will enhance their extraction results. While it may seem logical to double-bag for added protection, this approach can actually complicate the process. Multiple bags can create additional layers that hinder the flow of rosin, leading to inefficient extraction and potential clogging. Instead, it is advisable to use a single, appropriately sized bag that is designed for the specific material and press plate dimensions.

Lastly, a lack of attention to the pressing technique can also contribute to poor bag size selection. Users often focus solely on the bag dimensions without considering how the pressing process itself can affect the outcome. For instance, applying excessive pressure or heat can cause the bag to rupture, regardless of its size. Therefore, it is vital to adopt a holistic approach that encompasses both bag selection and pressing techniques to achieve the best results.

In conclusion, understanding the common mistakes associated with choosing the right bag size for a rosin press plate is essential for anyone looking to optimize their extraction process. By carefully considering the dimensions of the press plate, the characteristics of the material, the thickness of the bag, and the pressing technique, users can significantly enhance their rosin extraction experience. Ultimately, making informed decisions in these areas will lead to higher yields and superior quality rosin, ensuring a more successful and satisfying outcome.

Tips for Achieving Optimal Results with the Right Bag Size on Your Rosin Press Plate

When it comes to achieving optimal results with a rosin press, understanding the relationship between bag size and plate size is crucial. The rosin extraction process relies heavily on the efficient transfer of heat and pressure, and the right bag size can significantly influence the quality and yield of the final product. Therefore, it is essential to consider various factors that contribute to the effectiveness of your rosin press setup.

To begin with, the size of the rosin press plates plays a pivotal role in determining the appropriate bag size. Generally, the dimensions of the plates dictate the maximum size of the bag that can be used without compromising the extraction process. For instance, if you are working with a smaller plate size, using a bag that is too large can lead to uneven pressure distribution. This unevenness can result in suboptimal extraction, as some areas may not receive adequate heat or pressure, leading to a lower yield and potentially lower quality rosin. Conversely, using a bag that is too small for larger plates can also be detrimental, as it may not allow for sufficient material to be processed, thereby limiting the overall efficiency of the extraction.

Moreover, the type of material being pressed is another critical factor to consider when selecting the right bag size. Different materials, such as flower, hash, or kief, have varying densities and moisture contents, which can affect how they respond to heat and pressure. For example, when pressing flower, a slightly larger bag may be beneficial to accommodate the expansion of the material during the extraction process. This expansion can create a more even distribution of pressure, ultimately leading to a higher yield. On the other hand, when working with denser materials like hash, a smaller bag may be more appropriate, as it can help maintain the integrity of the material and prevent it from becoming overly compressed.

In addition to considering the size of the bag in relation to the plates and material, it is also important to pay attention to the quality of the bags themselves. High-quality, micron-filtered bags are essential for ensuring that only the desired compounds are extracted while preventing unwanted plant material from contaminating the rosin. Using bags that are too thin or poorly constructed can lead to tearing or leaking during the pressing process, which can compromise the quality of the final product. Therefore, investing in durable, well-made bags that are specifically designed for rosin extraction is a wise decision.

Furthermore, experimenting with different bag sizes can yield valuable insights into your specific setup. Each rosin press and material combination may respond differently, and what works best for one scenario may not be ideal for another. By testing various bag sizes, you can fine-tune your process to achieve the best possible results. Keeping detailed notes on your experiments can help you identify patterns and preferences, ultimately leading to a more efficient and effective extraction process.

In conclusion, understanding the maximum bag size for different rosin press plate sizes is essential for achieving optimal results. By carefully considering the relationship between plate size, material type, bag quality, and experimentation, you can enhance your rosin extraction process. This attention to detail not only improves yield and quality but also elevates the overall experience of working with a rosin press, allowing you to produce high-quality extracts with confidence.