What Micron Bag Should You Use for Rosin Pressing?

Micron Bag Sizes: Which One is Right for Your Rosin Press?

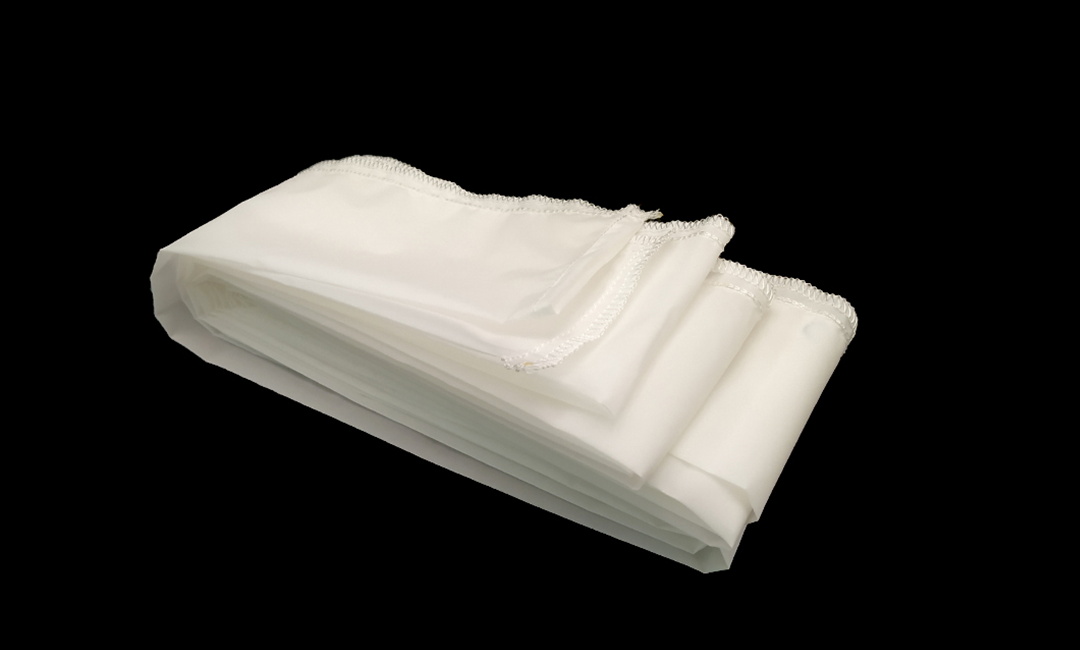

When it comes to rosin pressing, the choice of micron bag size is crucial for achieving optimal results. Micron bags, also known as filter bags, are designed to separate the plant material from the extracted rosin, and the size of the micron filter plays a significant role in determining the quality and yield of the final product. Understanding the various micron bag sizes available and their respective applications can help you make an informed decision that aligns with your pressing goals.

Micron sizes typically range from 25 to 160 microns, with each size offering distinct advantages and disadvantages. For instance, bags with a smaller micron size, such as 25 or 37 microns, are often favored for their ability to filter out finer particles, resulting in a cleaner and more refined rosin. This is particularly beneficial for those who prioritize purity and clarity in their extracts. However, while smaller micron bags can yield a higher quality product, they may also lead to lower overall yields, as they can trap more of the desirable resin along with the unwanted plant material.

On the other hand, larger micron bags, such as those measuring 90 or 120 microns, tend to allow more plant material to pass through, which can result in a higher yield. This is advantageous for users who are focused on maximizing their output, especially when working with larger quantities of material. However, the trade-off is that the final product may contain more impurities, which can affect the overall quality and flavor profile of the rosin. Therefore, it is essential to consider your priorities—whether you value yield or purity more—when selecting the appropriate micron bag size.

In addition to the size of the micron bag, the type of material being pressed also influences the choice of micron size. For example, when pressing high-quality flower, a smaller micron bag may be more suitable to ensure that the final product is free from unwanted plant matter. Conversely, when working with lower-quality material or trim, a larger micron bag may be more effective in extracting a greater volume of rosin without being overly concerned about the presence of minor impurities.

Moreover, the pressing technique and equipment used can also dictate the ideal micron bag size. For instance, if you are using a hydraulic press that applies significant pressure, a smaller micron bag may be necessary to prevent the finer particles from clogging the filter and compromising the extraction process. Conversely, if you are using a lower-pressure method, a larger micron bag may suffice, allowing for a more straightforward extraction without the risk of clogging.

Ultimately, the decision on which micron bag to use for rosin pressing should be based on a combination of factors, including the quality of the starting material, the desired characteristics of the final product, and the specific pressing method employed. By carefully considering these elements, you can select the micron bag size that best aligns with your goals, ensuring that you achieve the highest quality rosin possible. As you gain experience in rosin pressing, you may find that experimenting with different micron sizes can lead to a deeper understanding of how each size affects the extraction process, allowing you to refine your technique and enhance your results over time.

The Importance of Micron Bag Material in Rosin Extraction

When it comes to rosin pressing, the choice of micron bag material plays a crucial role in determining the quality and yield of the final product. Rosin extraction is a solventless method that utilizes heat and pressure to extract essential oils from plant material, primarily cannabis. The micron bag serves as a filter during this process, allowing the desirable compounds to pass through while retaining unwanted plant matter. Therefore, understanding the significance of micron bag material is essential for anyone looking to achieve optimal results in rosin extraction.

The micron size of the bag is one of the most critical factors to consider. Micron bags are available in various sizes, typically ranging from 25 to 160 microns. Smaller micron sizes, such as 25 or 37 microns, are often preferred for high-quality extracts because they allow for the filtration of finer particles, resulting in a cleaner product. However, using a bag that is too small can lead to clogging, which may hinder the extraction process and reduce overall yield. Conversely, larger micron sizes, such as 90 or 120 microns, can facilitate a higher yield but may allow more plant material to pass through, potentially compromising the purity of the extract. Therefore, selecting the appropriate micron size is a balancing act that depends on the specific goals of the extraction process.

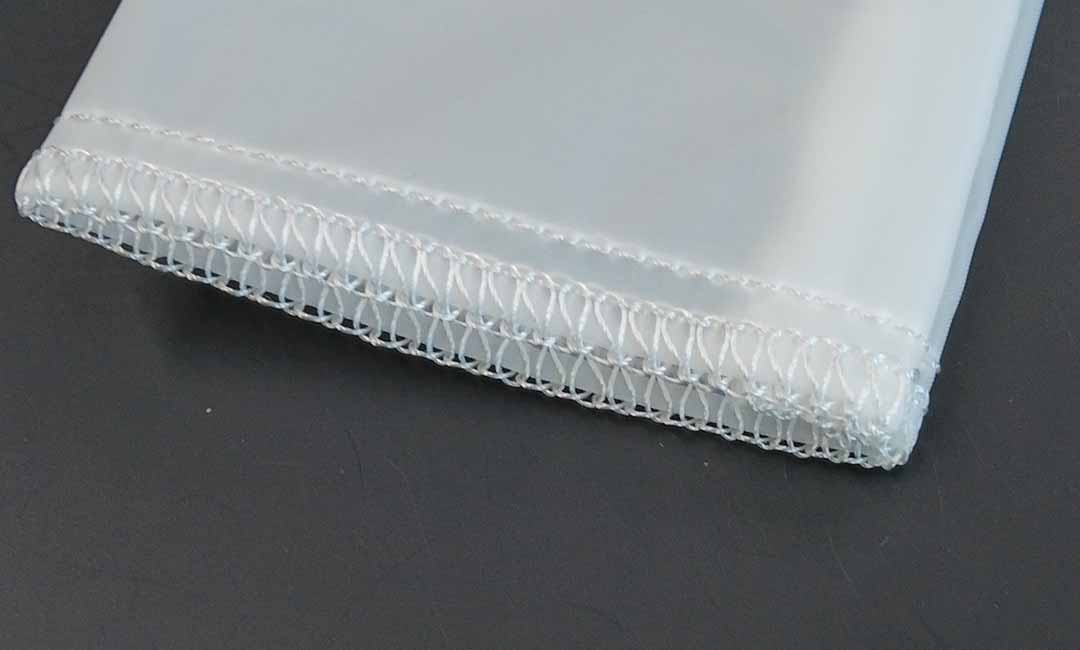

In addition to micron size, the material of the bag itself is equally important. Micron bags are typically made from nylon or polyester, each offering distinct advantages and disadvantages. Nylon bags are known for their durability and resistance to tearing, making them a popular choice among experienced extractors. They can withstand the high pressures involved in rosin pressing without compromising their integrity. On the other hand, polyester bags are often more affordable and can provide adequate filtration for many users. However, they may not be as robust as nylon, which could lead to issues during the extraction process if the bag fails.

Moreover, the weave of the micron bag material can also influence the extraction outcome. A tighter weave can provide better filtration, ensuring that only the desired compounds are extracted. However, this can also increase the likelihood of clogging, particularly when working with moist or resinous plant material. Conversely, a looser weave may allow for a smoother flow of material but could result in a less refined extract. Therefore, it is essential to consider both the micron size and the weave of the bag when selecting the appropriate material for rosin pressing.

Furthermore, the choice of micron bag can also impact the flavor and aroma of the final product. The extraction process is not solely about yield; it is also about preserving the terpenes and cannabinoids that contribute to the overall experience of the extract. A well-chosen micron bag can help retain these volatile compounds, resulting in a more flavorful and aromatic product. This aspect is particularly important for connoisseurs who prioritize the sensory qualities of their extracts.

In conclusion, the importance of micron bag material in rosin extraction cannot be overstated. The right micron size, material, and weave can significantly influence both the yield and quality of the final product. By carefully considering these factors, extractors can enhance their rosin pressing experience, ultimately leading to superior extracts that meet their specific needs and preferences. As the popularity of rosin extraction continues to grow, understanding the nuances of micron bag selection will remain a vital component of the process.

Comparing Different Micron Bag Brands for Rosin Pressing

When it comes to rosin pressing, the choice of micron bag is crucial for achieving optimal results. The micron bag serves as a filter that separates the desirable rosin from the plant material, and the effectiveness of this process largely depends on the quality and specifications of the bag used. As such, comparing different micron bag brands can provide valuable insights into which options may best suit your pressing needs.

One of the most prominent brands in the market is the “PurePressure” micron bags. Known for their durability and high-quality materials, these bags are designed to withstand the heat and pressure involved in the rosin extraction process. With a range of micron sizes available, from 25 to 160 microns, PurePressure allows users to select the appropriate filter for their specific strain and desired yield. The bags are also constructed with a double-stitched design, which minimizes the risk of tearing during pressing, thus ensuring a cleaner extraction.

Another noteworthy brand is “BHO Gear,” which offers a variety of micron bags tailored for rosin pressing. Their bags are made from food-grade nylon, ensuring that no harmful chemicals leach into the rosin during extraction. BHO Gear provides micron sizes ranging from 37 to 160 microns, allowing for versatility in filtering. Users often praise the brand for its affordability without compromising on quality, making it an attractive option for both novice and experienced extractors alike.

In contrast, “Rosin Tech” micron bags are specifically engineered for high-performance extraction. These bags are crafted with a unique mesh design that enhances the flow of rosin while effectively trapping unwanted plant material. Available in sizes from 25 to 160 microns, Rosin Tech bags are particularly favored for their ability to produce a high yield of clean rosin. Additionally, the brand emphasizes the importance of using the right micron size for different strains, which can significantly impact the flavor and potency of the final product.

Furthermore, “ExtractCraft” offers a range of micron bags that are well-regarded for their strength and reliability. Their bags are designed to handle high pressures, making them suitable for both small-scale and commercial operations. ExtractCraft provides a variety of micron sizes, allowing users to experiment with different strains and extraction techniques. The brand’s commitment to quality ensures that users can achieve consistent results, which is essential for those looking to refine their rosin pressing skills.

As one evaluates these different brands, it is essential to consider not only the micron size but also the intended use and personal preferences. For instance, while some users may prioritize yield, others may focus on flavor retention or ease of use. Additionally, the choice of micron bag can also be influenced by the specific strain being pressed, as different strains may yield varying results depending on the micron size used.

In conclusion, selecting the right micron bag for rosin pressing involves careful consideration of various factors, including brand reputation, material quality, and micron size. Each brand offers unique advantages that cater to different pressing needs, making it essential for users to assess their priorities and preferences. By comparing the features and benefits of brands like PurePressure, BHO Gear, Rosin Tech, and ExtractCraft, extractors can make informed decisions that enhance their rosin pressing experience and ultimately lead to superior results.

How to Properly Use Micron Bags for Optimal Rosin Yield

When it comes to rosin pressing, the choice of micron bags plays a crucial role in determining the quality and yield of the final product. To achieve optimal results, it is essential to understand how to properly use these bags throughout the pressing process. Micron bags, which are designed to filter out unwanted plant material while allowing the desirable resin to pass through, come in various sizes, typically ranging from 25 to 160 microns. The selection of the appropriate micron size is the first step in ensuring a successful extraction.

To begin with, it is important to consider the type of material being pressed. For instance, if you are working with high-quality flower, a smaller micron bag, such as one with a 25 or 37-micron rating, is often recommended. These smaller sizes effectively filter out the finer plant particles, resulting in a cleaner and more potent rosin. Conversely, when pressing hash or kief, a larger micron bag, such as one rated at 90 or 120 microns, may be more suitable. This is because the larger particles in hash can benefit from a bit more room to pass through, allowing for a higher yield without compromising the quality of the extract.

Once the appropriate micron bag has been selected, the next step is to prepare the material for pressing. It is advisable to break down the flower or hash into smaller pieces to maximize surface area and ensure even extraction. Additionally, pre-pressing the material into a compact puck can help facilitate a more uniform distribution of heat and pressure during the pressing process. This step is particularly important, as unevenly packed material can lead to inconsistent yields and quality.

After preparing the material, it is essential to load it into the micron bag correctly. When filling the bag, avoid overpacking, as this can restrict the flow of resin and lead to suboptimal extraction. Instead, aim for a loose, even distribution of the material within the bag. Once filled, it is advisable to fold the top of the bag over to prevent any spillage during the pressing process. Securing the bag with a heat-resistant clip or tie can further ensure that the contents remain contained.

As you proceed to the pressing stage, maintaining the right temperature and pressure is vital for achieving optimal yields. Generally, a temperature range of 180 to 220 degrees Fahrenheit is recommended, depending on the specific material being pressed. It is also important to apply consistent pressure, as fluctuating pressure can lead to uneven extraction and lower quality rosin. Monitoring both temperature and pressure throughout the process will help ensure that the resin is extracted efficiently without degrading its quality.

Finally, after the pressing is complete, allow the micron bag to cool before handling it. This cooling period helps solidify the rosin, making it easier to collect. When extracting the rosin from the bag, be gentle to avoid tearing the fabric, which could introduce unwanted plant material into the final product. By following these guidelines and understanding the nuances of micron bag selection and usage, you can significantly enhance your rosin pressing experience, leading to higher yields and superior quality extracts. Ultimately, the careful attention to detail in each step of the process will yield the best results, allowing you to enjoy the fruits of your labor with confidence.