What to Do When Rosin Sticks to the Bag: Tips for a Cleaner Extraction

Proper Bag Selection for Rosin Extraction

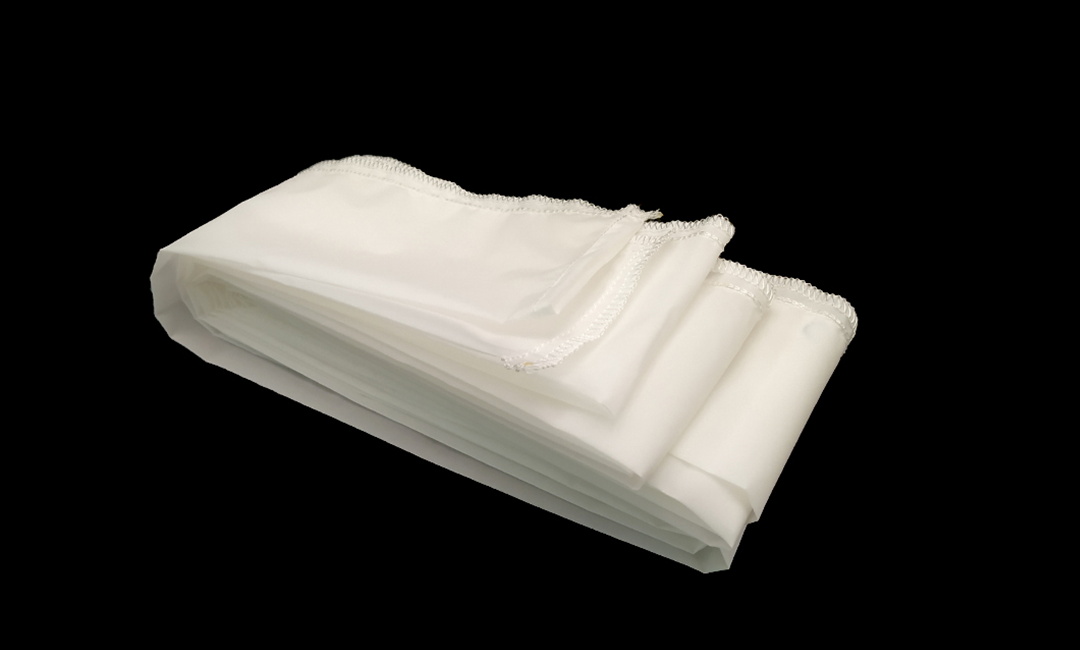

When engaging in the process of rosin extraction, the selection of the appropriate bag is a critical factor that can significantly influence the quality and efficiency of the extraction. The bags used in this process serve as a filter, allowing the desired rosin to pass through while retaining unwanted plant material. Therefore, understanding the various types of bags available and their specific characteristics is essential for achieving optimal results.

First and foremost, it is important to consider the micron size of the bag. Micron size refers to the diameter of the holes in the bag’s mesh, which directly impacts the filtration process. Generally, bags with a lower micron size, such as 25 to 90 microns, are ideal for extracting finer particles, while those with a higher micron size, such as 160 to 220 microns, are better suited for coarser materials. Selecting the right micron size not only ensures that the rosin is free from contaminants but also helps in maximizing yield. A bag that is too fine may lead to clogging, while one that is too coarse may allow unwanted plant material to pass through, compromising the purity of the final product.

In addition to micron size, the material of the bag plays a significant role in the extraction process. Most rosin extraction bags are made from nylon or polyester, both of which offer durability and resistance to heat. However, the choice between these materials can affect the overall performance. Nylon bags are often preferred for their strength and ability to withstand higher pressures, making them suitable for larger quantities of material. On the other hand, polyester bags are typically more affordable and can be effective for smaller extractions. It is advisable to assess the specific requirements of the extraction process and choose a bag material that aligns with those needs.

Moreover, the size of the bag should not be overlooked. Using a bag that is appropriately sized for the amount of material being processed is crucial. A bag that is too small may lead to overpacking, which can hinder the flow of rosin and increase the likelihood of the material sticking to the bag. Conversely, a bag that is excessively large may result in wasted space and inefficient extraction. Therefore, it is essential to match the bag size with the quantity of material to ensure a smooth and effective extraction process.

Another important consideration is the design of the bag. Some bags come with additional features, such as reinforced seams or double-layer construction, which can enhance their durability and performance. These features can be particularly beneficial when dealing with high-pressure extraction, as they reduce the risk of tearing or leaking. Investing in high-quality bags with these enhancements can lead to a more efficient extraction process and a cleaner final product.

Finally, it is advisable to conduct a test run with the selected bag before committing to a larger extraction. This preliminary step allows for the evaluation of the bag’s performance in terms of filtration efficiency and yield. By assessing the results of the test run, adjustments can be made to the bag selection or extraction parameters, ensuring that the final extraction meets the desired standards.

In conclusion, proper bag selection is a fundamental aspect of successful rosin extraction. By considering factors such as micron size, material, size, and design, one can significantly improve the quality and efficiency of the extraction process. Taking the time to choose the right bag not only enhances the purity of the rosin but also minimizes the risk of material sticking to the bag, ultimately leading to a cleaner and more satisfying extraction experience.

Techniques to Prevent Rosin from Sticking

Rosin extraction has become a popular method for obtaining high-quality concentrates from cannabis flower. However, one common issue that many extractors face is rosin sticking to the bag during the extraction process. This can be frustrating and lead to a lower yield of product. Fortunately, there are several techniques that can help prevent rosin from sticking to the bag and ensure a cleaner extraction.

One of the most important factors to consider when trying to prevent rosin from sticking to the bag is the temperature at which the extraction is performed. Rosin is a sticky substance that becomes more pliable and easier to work with at higher temperatures. However, if the temperature is too high, the rosin can become too runny and may seep through the bag, causing a messy extraction. It is important to find the right balance of temperature to ensure a clean extraction.

Another important factor to consider is the pressure applied during the extraction process. Too much pressure can cause the rosin to be forced through the bag, leading to a messy extraction. It is important to apply just enough pressure to extract the rosin without causing it to stick to the bag. This may require some trial and error to find the right pressure for your specific extraction setup.

Using the right type of bag can also help prevent rosin from sticking during the extraction process. There are several different types of bags available, including nylon and polyester. Nylon bags are more porous and can allow the rosin to seep through, while polyester bags are more durable and less likely to stick. It is important to choose the right type of bag for your extraction setup to ensure a cleaner extraction.

In addition to using the right type of bag, it is also important to properly prepare the bag before starting the extraction process. This can include pre-pressing the flower to ensure an even distribution of pressure, as well as folding the bag in a way that minimizes the chances of the rosin sticking to the sides. Taking the time to properly prepare the bag can help prevent rosin from sticking and ensure a cleaner extraction.

Finally, cleaning the bag after each use can help prevent rosin from sticking during future extractions. Residual rosin left in the bag can harden and cause the next extraction to stick. It is important to thoroughly clean the bag after each use to ensure a clean extraction every time.

In conclusion, there are several techniques that can help prevent rosin from sticking to the bag during the extraction process. By carefully controlling the temperature, pressure, and type of bag used, as well as properly preparing and cleaning the bag, extractors can ensure a cleaner extraction and a higher yield of product. With a little practice and attention to detail, rosin extractors can overcome the challenge of rosin sticking to the bag and enjoy a smoother extraction process.

Cleaning Methods for Sticky Rosin Bags

Rosin extraction has become a popular method for obtaining high-quality concentrates from cannabis and other plant materials. However, one common issue that many extractors face is when the rosin sticks to the bag during the extraction process. This can be frustrating and lead to a messy cleanup, but there are several tips and techniques that can help you avoid this problem and achieve a cleaner extraction.

One of the most important things to keep in mind when dealing with sticky rosin bags is to use the right type of material for your bags. Silicone bags are often recommended for rosin extraction, as they are non-stick and can easily be cleaned with a solvent such as isopropyl alcohol. If you are using a different type of bag, make sure it is made from a material that is resistant to sticking, such as PTFE or nylon.

Another tip for preventing rosin from sticking to the bag is to use the correct temperature and pressure during the extraction process. If the temperature is too high, the rosin can become too runny and seep through the bag, causing it to stick. On the other hand, if the temperature is too low, the rosin may not flow properly and can also stick to the bag. It is important to find the right balance of temperature and pressure to ensure a clean extraction.

If you do find that rosin has stuck to the bag during the extraction process, there are several cleaning methods that can help you remove the residue and salvage your concentrate. One common method is to freeze the bag, which can help harden the rosin and make it easier to peel off. Simply place the bag in the freezer for a few hours, then gently peel the rosin off with a tool such as a dabber or scraper.

Another cleaning method for sticky rosin bags is to use a solvent such as isopropyl alcohol or ethanol. Simply soak the bag in the solvent for a few minutes, then gently scrub the residue off with a brush or cloth. Be sure to rinse the bag thoroughly with water afterwards to remove any remaining solvent residue.

If the rosin is particularly stubborn and refuses to come off, you can try using a heat gun or hair dryer to soften the residue and make it easier to remove. Be careful not to overheat the bag, as this can cause damage to the material and affect the quality of your concentrate.

In conclusion, dealing with sticky rosin bags can be a frustrating experience, but with the right techniques and cleaning methods, you can achieve a cleaner extraction and salvage your concentrate. Remember to use the right type of material for your bags, maintain the correct temperature and pressure during extraction, and utilize cleaning methods such as freezing, solvent soaking, and heat application to remove stubborn residue. By following these tips, you can ensure a smoother extraction process and enjoy high-quality concentrates every time.

Best Practices for Efficient Rosin Extraction

When engaging in the process of rosin extraction, achieving a clean and efficient yield is paramount. One common challenge that many extractors face is the tendency for rosin to stick to the extraction bag, which can lead to wasted product and frustration. To mitigate this issue, it is essential to adopt best practices that enhance the overall efficiency of the extraction process. By understanding the nuances of temperature, pressure, and material preparation, extractors can significantly improve their results.

First and foremost, temperature control plays a critical role in the extraction process. The ideal temperature for rosin extraction typically ranges between 180°F to 220°F. Operating within this range allows for optimal oil flow while minimizing the risk of burning the material. It is advisable to experiment with different temperatures to find the sweet spot that yields the best results for specific strains or types of material. Additionally, preheating the extraction plates can help ensure that the rosin flows more freely, reducing the likelihood of it adhering to the bag.

In conjunction with temperature, pressure is another vital factor that influences the efficiency of rosin extraction. Applying the right amount of pressure can help to maximize the yield while ensuring that the rosin does not become overly viscous and sticky. Generally, a pressure range of 600 to 1,200 psi is recommended, but this can vary based on the material being used. It is beneficial to start with lower pressure and gradually increase it, allowing for a more controlled extraction process. This method not only helps in achieving a cleaner extraction but also aids in preserving the flavor and aroma of the final product.

Moreover, the preparation of the material prior to extraction cannot be overlooked. Ensuring that the starting material is adequately dried and cured is essential for achieving a high-quality yield. Excess moisture can lead to undesirable results, including a sticky residue that clings to the extraction bag. Therefore, it is advisable to use well-cured flower or hash that has been properly stored to maintain its integrity. Additionally, grinding the material to a consistent size can facilitate a more even extraction, allowing for better oil flow and reducing the chances of clogging the bag.

Furthermore, the choice of extraction bags is crucial in preventing rosin from sticking. High-quality, micron-rated bags are designed to allow for optimal oil flow while filtering out unwanted plant material. It is recommended to use bags with a micron size that corresponds to the type of material being extracted. For instance, using a 90-micron bag for flower can yield better results than a larger micron size, as it allows for a more refined extraction. Additionally, pre-washing the bags with warm water can help to create a non-stick surface, further reducing the likelihood of rosin adhering to the bag.

Lastly, maintaining a clean workspace and equipment is essential for achieving a successful extraction. Residue from previous extractions can contaminate new batches and contribute to stickiness. Regularly cleaning extraction plates, bags, and tools ensures that each extraction is performed under optimal conditions, leading to a cleaner and more efficient process.

In conclusion, by focusing on temperature control, pressure application, material preparation, bag selection, and workspace cleanliness, extractors can significantly enhance their rosin extraction process. Implementing these best practices not only minimizes the chances of rosin sticking to the bag but also maximizes yield and quality, ultimately leading to a more satisfying extraction experience.