Why Industrial Spiral Belts Are Ideal for Heavy-Duty Applications

Durability and Strength of Industrial Spiral Belts

Industrial spiral belts have emerged as a pivotal component in various heavy-duty applications, primarily due to their exceptional durability and strength. These belts are engineered to withstand the rigors of demanding environments, making them an ideal choice for industries such as food processing, packaging, and material handling. The construction of industrial spiral belts typically involves high-quality materials that are designed to endure significant wear and tear, ensuring a long service life even under the most challenging conditions.

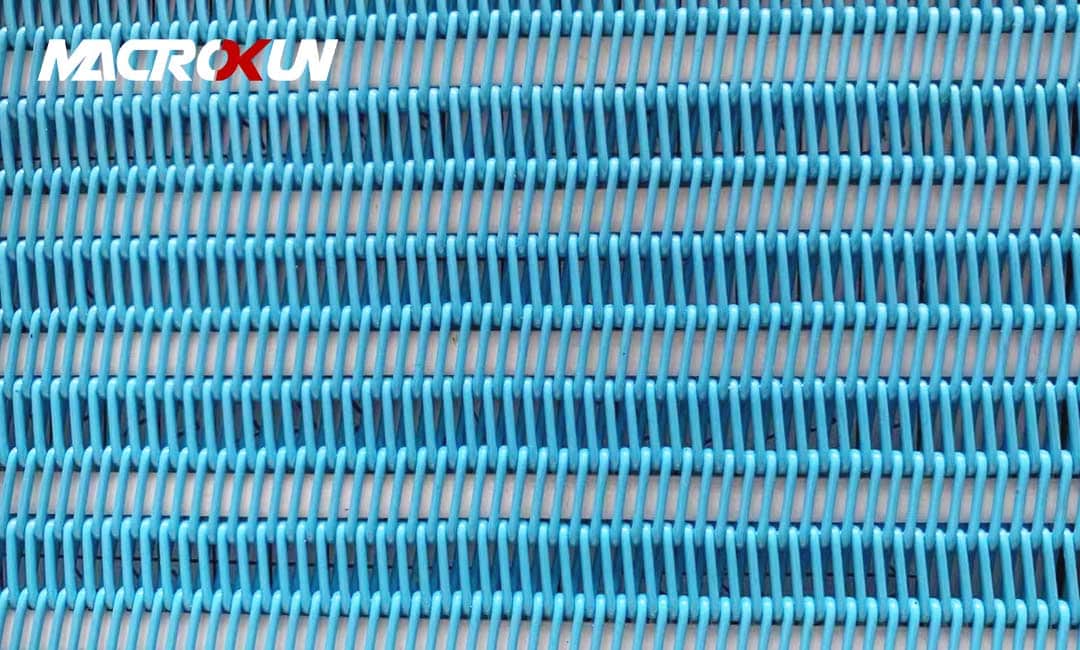

One of the key factors contributing to the durability of industrial spiral belts is their unique design. Unlike traditional flat belts, spiral belts are constructed with interlocking spirals that provide a continuous surface for transporting materials. This design not only enhances the structural integrity of the belt but also allows for better load distribution. As a result, the belts can handle heavier loads without compromising their performance. The ability to maintain strength under pressure is crucial in heavy-duty applications, where equipment is often subjected to extreme conditions.

Moreover, the materials used in the manufacturing of industrial spiral belts play a significant role in their strength. Many of these belts are made from robust polymers or metal, which are resistant to abrasion, chemicals, and temperature fluctuations. This resistance is particularly important in industries where exposure to harsh substances is common. For instance, in food processing, belts must not only endure mechanical stress but also resist contamination from various food products. The use of food-grade materials ensures that the belts meet stringent hygiene standards while maintaining their durability.

In addition to their material properties, industrial spiral belts are designed for easy maintenance and repair. This aspect is vital in heavy-duty applications, where downtime can lead to significant financial losses. The modular nature of spiral belts allows for quick replacement of individual sections without the need to replace the entire belt. This feature not only reduces maintenance costs but also minimizes operational disruptions, enabling businesses to maintain productivity levels.

Furthermore, the versatility of industrial spiral belts enhances their appeal in heavy-duty applications. They can be customized to meet specific operational requirements, such as varying widths, lengths, and surface textures. This adaptability ensures that businesses can implement spiral belts in a wide range of processes, from cooling and drying to conveying and sorting. The ability to tailor these belts to fit unique applications further solidifies their position as a preferred choice in industries that demand reliability and efficiency.

Another significant advantage of industrial spiral belts is their ability to operate in extreme conditions. Whether it is high temperatures in baking processes or low temperatures in freezing applications, these belts maintain their performance without succumbing to deformation or failure. This resilience is essential for industries that require consistent operation under fluctuating environmental conditions.

In conclusion, the durability and strength of industrial spiral belts make them an ideal solution for heavy-duty applications. Their unique design, robust materials, ease of maintenance, versatility, and ability to withstand extreme conditions collectively contribute to their effectiveness in demanding environments. As industries continue to evolve and face new challenges, the reliance on industrial spiral belts is likely to grow, ensuring that they remain a cornerstone of efficient and reliable operations in various sectors.

Enhanced Efficiency in Material Handling

Industrial spiral belts are a crucial component in material handling systems, especially in heavy-duty applications where efficiency and durability are paramount. These belts are designed to withstand the rigors of industrial environments, providing a reliable and efficient solution for moving materials throughout the production process.

One of the key advantages of industrial spiral belts is their ability to handle heavy loads with ease. The spiral design of these belts allows for a larger surface area to come into contact with the material being transported, which helps distribute the weight more evenly and reduce the risk of damage or wear. This makes them ideal for applications where large volumes of heavy materials need to be moved quickly and efficiently.

In addition to their strength and durability, industrial spiral belts are also highly customizable to meet the specific needs of different industries and applications. They can be made from a variety of materials, including stainless steel, carbon steel, and plastic, depending on the requirements of the application. This flexibility allows for greater versatility in material handling systems, ensuring that they can adapt to changing production demands.

Another key benefit of industrial spiral belts is their low maintenance requirements. Unlike traditional conveyor belts, which can be prone to wear and tear over time, spiral belts are designed to withstand heavy use without the need for frequent repairs or replacements. This not only reduces downtime and maintenance costs but also ensures a more reliable and efficient material handling system overall.

Furthermore, industrial spiral belts are known for their high efficiency in material handling. The spiral design of these belts allows for smooth and continuous movement of materials, reducing the risk of jams or blockages that can slow down production. This results in faster processing times and increased productivity, making them an ideal choice for industries where speed and efficiency are critical.

In conclusion, industrial spiral belts are an ideal solution for heavy-duty material handling applications due to their strength, durability, customization options, low maintenance requirements, and high efficiency. These belts provide a reliable and efficient way to move materials throughout the production process, ensuring smooth and continuous operation even in the most demanding industrial environments. Whether you are in the manufacturing, food processing, or logistics industry, industrial spiral belts can help improve the efficiency and productivity of your material handling system.

Versatility in Various Heavy-Duty Industries

Industrial spiral belts are a crucial component in many heavy-duty applications across various industries. These belts are designed to withstand high temperatures, heavy loads, and harsh operating conditions, making them ideal for use in demanding environments. In this article, we will explore the versatility of industrial spiral belts in various heavy-duty industries and why they are the preferred choice for many applications.

One of the key reasons why industrial spiral belts are ideal for heavy-duty applications is their durability. These belts are typically made from high-quality materials such as stainless steel or carbon steel, which are known for their strength and resilience. This allows industrial spiral belts to withstand the rigors of heavy-duty use without succumbing to wear and tear.

In addition to their durability, industrial spiral belts are also highly versatile. They can be customized to meet the specific requirements of different applications, making them suitable for a wide range of industries. Whether it’s conveying heavy loads in a manufacturing plant or filtering wastewater in a treatment facility, industrial spiral belts can be tailored to suit the needs of the application.

Another key advantage of industrial spiral belts is their ability to operate at high temperatures. Many heavy-duty applications involve processes that generate heat, such as drying, baking, or curing. Industrial spiral belts are designed to withstand these high temperatures without losing their structural integrity, making them an ideal choice for such applications.

Furthermore, industrial spiral belts are easy to maintain, which is essential in heavy-duty industries where downtime can be costly. These belts are designed for easy cleaning and maintenance, allowing operators to keep them in optimal working condition with minimal effort. This helps to reduce downtime and ensure that operations run smoothly and efficiently.

Industrial spiral belts are used in a wide range of heavy-duty industries, including food processing, automotive manufacturing, and wastewater treatment. In the food processing industry, these belts are used for conveying, cooling, and freezing food products. Their durability and ability to operate at high temperatures make them well-suited for the demanding requirements of food processing applications.

In the automotive manufacturing industry, industrial spiral belts are used for conveying parts through various stages of production. These belts are designed to withstand heavy loads and high temperatures, making them ideal for use in the harsh operating conditions of automotive manufacturing plants.

In the wastewater treatment industry, industrial spiral belts are used for dewatering sludge and filtering wastewater. These belts are designed to handle the abrasive nature of wastewater and can withstand prolonged exposure to chemicals and contaminants. Their durability and versatility make them an essential component in wastewater treatment facilities.

In conclusion, industrial spiral belts are ideal for heavy-duty applications in various industries due to their durability, versatility, and ability to operate at high temperatures. These belts are designed to withstand the rigors of heavy-duty use and can be customized to meet the specific requirements of different applications. Whether it’s conveying heavy loads, filtering wastewater, or dewatering sludge, industrial spiral belts are the preferred choice for many heavy-duty industries.