Why Polyester Belts Are Essential for Paper Drying Applications

Increased Efficiency in Paper Drying Process

Polyester belts play a crucial role in the paper drying process, providing essential support and efficiency to the overall operation. These belts are specifically designed to withstand the high temperatures and pressures involved in the drying stage of paper production, making them an indispensable component in the industry. In this article, we will explore the reasons why polyester belts are essential for paper drying applications and how they contribute to increased efficiency in the process.

One of the key advantages of using polyester belts in paper drying applications is their ability to withstand high temperatures. The drying stage of paper production involves subjecting the paper to heat in order to remove moisture and achieve the desired level of dryness. Polyester belts are able to withstand temperatures of up to 200 degrees Celsius, making them ideal for this purpose. This high heat resistance ensures that the belts remain intact and functional throughout the drying process, reducing the risk of downtime and maintenance issues.

In addition to their heat resistance, polyester belts are also highly durable and long-lasting. The continuous operation of paper drying machines puts a significant amount of stress on the belts, requiring them to be able to withstand constant movement and tension. Polyester belts are known for their strength and resilience, making them a reliable choice for paper drying applications. Their durability ensures that they can withstand the rigors of the drying process without experiencing premature wear or damage, leading to increased efficiency and productivity.

Another benefit of using polyester belts in paper drying applications is their low friction properties. The smooth surface of polyester belts reduces friction between the belt and the paper, allowing for smooth and efficient movement of the paper through the drying machine. This low friction helps to prevent damage to the paper and ensures that it is dried evenly and consistently. By reducing friction, polyester belts contribute to a more efficient drying process, resulting in higher quality paper products.

Polyester belts are also known for their excellent moisture resistance. During the drying process, paper is exposed to high temperatures and pressures, which can create a humid environment. Polyester belts are able to resist moisture and humidity, preventing them from becoming damp or swollen. This moisture resistance helps to maintain the integrity of the belts and ensures that they remain effective in drying the paper. By using polyester belts with high moisture resistance, paper manufacturers can achieve better results in the drying process and produce high-quality paper products.

In conclusion, polyester belts are essential for paper drying applications due to their high heat resistance, durability, low friction properties, and moisture resistance. These belts play a crucial role in the efficiency of the paper drying process, ensuring smooth operation and high-quality results. By choosing polyester belts for paper drying applications, manufacturers can improve the overall efficiency of their operations and produce superior paper products.

Cost-Effectiveness of Polyester Belts

Polyester belts are an essential component in paper drying applications due to their cost-effectiveness and durability. These belts play a crucial role in the paper manufacturing process by carrying the wet paper through the drying section of the machine. In this article, we will explore why polyester belts are the preferred choice for paper drying applications and how they contribute to the overall efficiency of the process.

One of the main reasons why polyester belts are essential for paper drying applications is their cost-effectiveness. Polyester is a synthetic material that is known for its strength and durability, making it an ideal choice for industrial applications such as paper drying. Unlike other materials, polyester belts are resistant to wear and tear, which means they have a longer lifespan and require less frequent replacement. This not only reduces maintenance costs but also minimizes downtime, leading to increased productivity and efficiency in the paper manufacturing process.

In addition to their cost-effectiveness, polyester belts are also highly efficient in transferring heat during the drying process. The smooth surface of polyester belts allows for uniform heat distribution, which helps to dry the paper evenly and quickly. This is crucial in paper manufacturing, as uneven drying can result in poor quality paper that is prone to defects. By using polyester belts, paper manufacturers can ensure that their products meet the highest quality standards and are free from imperfections.

Furthermore, polyester belts are resistant to chemicals and moisture, making them suitable for the harsh conditions of paper drying applications. The chemical composition of polyester allows it to withstand exposure to various chemicals and solvents without degrading or losing its strength. This makes polyester belts an ideal choice for paper drying applications where the belts come into contact with water, steam, and other substances during the drying process. By using polyester belts, paper manufacturers can ensure that their equipment remains in optimal condition and continues to operate efficiently.

Another advantage of polyester belts is their flexibility and adaptability to different paper drying processes. Polyester belts can be customized to meet the specific requirements of each application, whether it involves high-speed drying or delicate paper grades. This versatility makes polyester belts a versatile solution for paper manufacturers looking to optimize their drying processes and achieve consistent results. By choosing polyester belts, paper manufacturers can tailor their equipment to meet the unique needs of their production line and ensure that their products are of the highest quality.

In conclusion, polyester belts are essential for paper drying applications due to their cost-effectiveness, durability, efficiency, and versatility. These belts play a crucial role in the paper manufacturing process by carrying the wet paper through the drying section of the machine and ensuring that it is dried evenly and quickly. By using polyester belts, paper manufacturers can reduce maintenance costs, minimize downtime, and achieve consistent results in their production processes. Overall, polyester belts are a reliable and efficient solution for paper drying applications, making them an essential component in the paper manufacturing industry.

Durability and Longevity of Polyester Belts

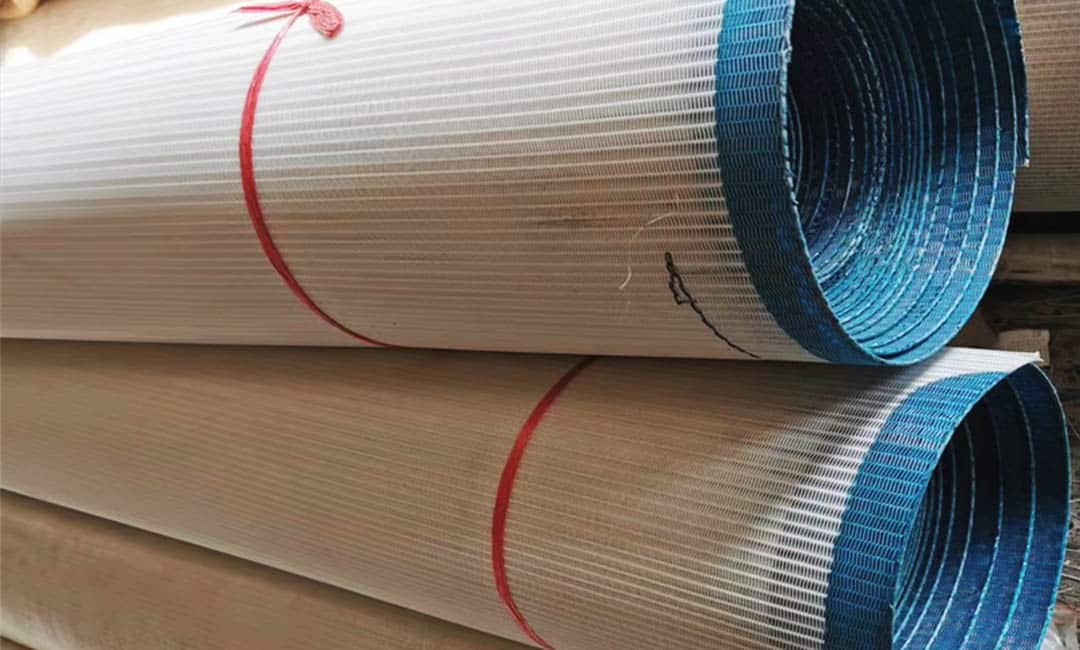

Polyester belts are an essential component in paper drying applications due to their durability and longevity. These belts play a crucial role in the paper manufacturing process by carrying the wet paper through the drying section of the machine. The ability of polyester belts to withstand high temperatures and heavy loads makes them ideal for this demanding application.

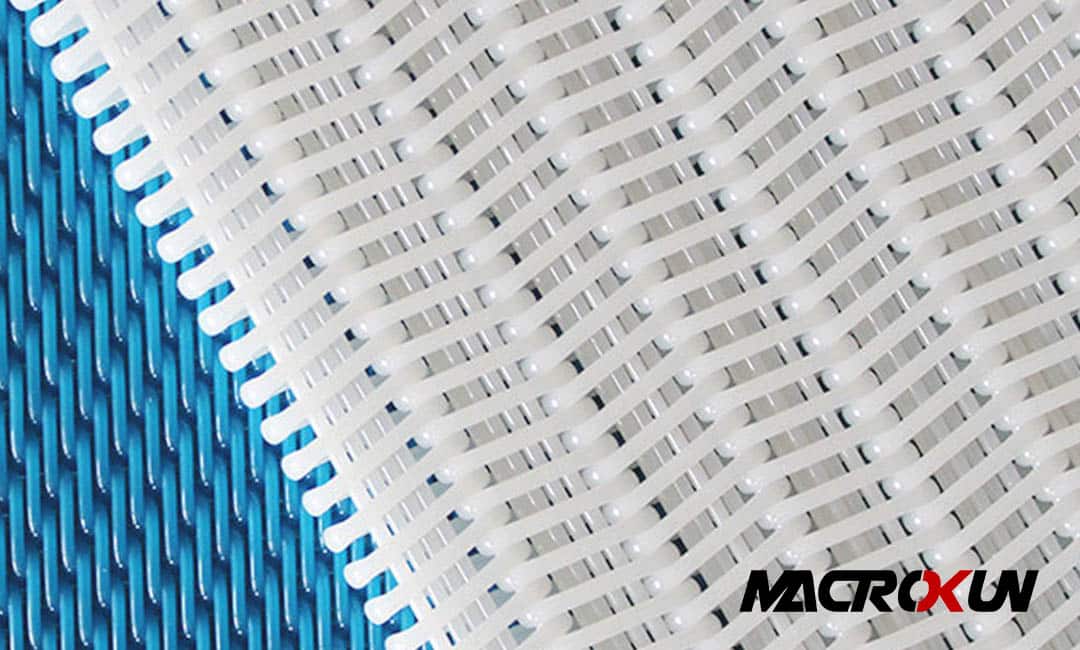

One of the key reasons why polyester belts are preferred for paper drying applications is their exceptional durability. These belts are made from high-quality polyester fibers that are woven together to create a strong and resilient material. This construction allows polyester belts to withstand the rigors of continuous use in a paper drying machine without experiencing premature wear or damage.

In addition to their durability, polyester belts are also known for their longevity. Unlike other types of belts that may need to be replaced frequently due to wear and tear, polyester belts have a long service life. This means that paper manufacturers can rely on these belts to perform consistently over an extended period, reducing downtime and maintenance costs.

Furthermore, polyester belts are resistant to moisture and chemicals, making them well-suited for the harsh conditions found in paper drying applications. The ability of these belts to resist degradation from water and chemicals ensures that they maintain their strength and integrity even when exposed to harsh environments.

Another advantage of polyester belts is their high temperature resistance. Paper drying machines operate at elevated temperatures to remove moisture from the paper quickly and efficiently. Polyester belts are able to withstand these high temperatures without losing their shape or strength, ensuring smooth and reliable operation in the drying section of the machine.

Moreover, polyester belts are easy to clean and maintain, further enhancing their longevity and performance. Regular cleaning and maintenance help to prevent the buildup of debris and contaminants on the belt surface, which can affect its performance and lifespan. With proper care, polyester belts can continue to deliver reliable performance in paper drying applications for years to come.

In conclusion, polyester belts are essential for paper drying applications due to their durability and longevity. These belts are able to withstand high temperatures, heavy loads, moisture, and chemicals, making them well-suited for the demanding conditions found in paper manufacturing. Their exceptional durability and longevity ensure that paper manufacturers can rely on polyester belts to deliver consistent performance over an extended period, reducing downtime and maintenance costs. With their high temperature resistance, resistance to moisture and chemicals, and ease of cleaning and maintenance, polyester belts are the ideal choice for paper drying applications.