Why Polyester Drying Fabric Belts Are the Future of Manufacturing

Durability and Longevity of Polyester Drying Fabric Belts

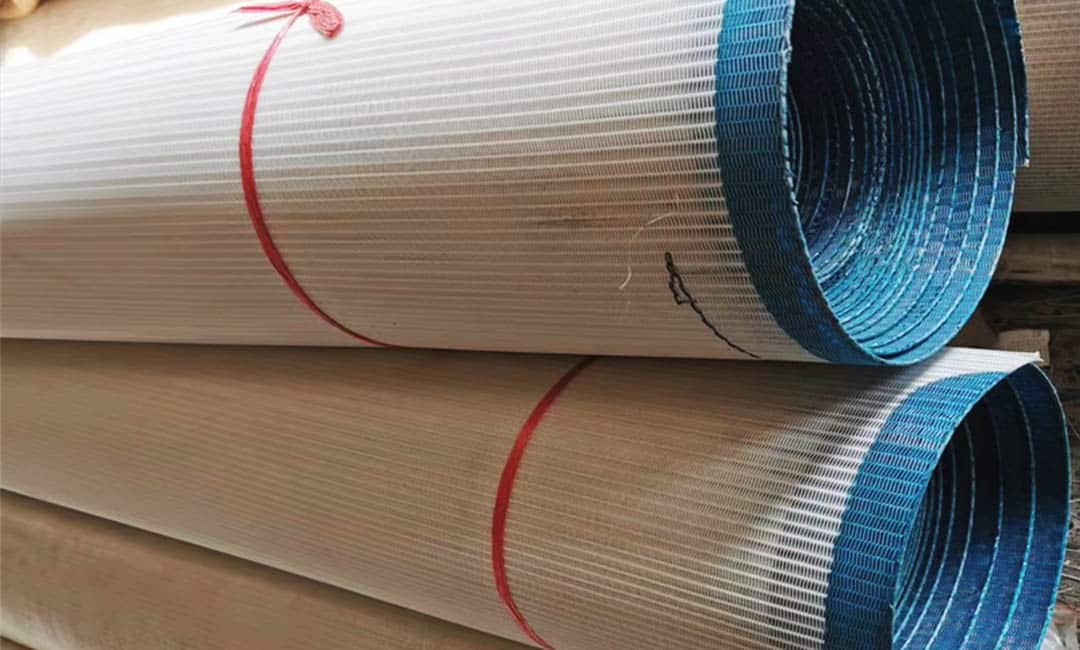

Polyester drying fabric belts have emerged as a pivotal component in the manufacturing sector, particularly in industries that require efficient drying processes. One of the most compelling reasons for their increasing adoption is their remarkable durability and longevity. Unlike traditional drying materials, polyester belts are engineered to withstand the rigors of continuous use, making them an ideal choice for high-demand environments. The inherent properties of polyester contribute significantly to its resilience; it is resistant to wear and tear, which is crucial in settings where belts are subjected to constant friction and exposure to various chemicals.

Moreover, the longevity of polyester drying fabric belts is further enhanced by their ability to maintain structural integrity under extreme conditions. These belts can endure high temperatures and humidity levels without compromising their performance. This characteristic is particularly beneficial in industries such as textiles and paper, where drying processes often involve significant heat and moisture. As a result, manufacturers can rely on polyester belts to deliver consistent performance over extended periods, reducing the need for frequent replacements and minimizing downtime.

In addition to their physical durability, polyester drying fabric belts also exhibit excellent resistance to environmental factors. They are less prone to degradation from UV exposure compared to other materials, which can be a critical factor in outdoor or semi-outdoor manufacturing settings. This resistance not only extends the lifespan of the belts but also ensures that they maintain their functionality and appearance over time. Consequently, businesses can achieve a higher return on investment, as the longevity of these belts translates into lower operational costs.

Furthermore, the maintenance of polyester drying fabric belts is relatively straightforward, which adds to their appeal in the manufacturing landscape. Regular cleaning and inspection can significantly prolong their lifespan, allowing manufacturers to implement simple maintenance routines that do not disrupt production schedules. This ease of maintenance is a stark contrast to other materials that may require specialized care or frequent adjustments, thereby streamlining operations and enhancing overall efficiency.

The adaptability of polyester also plays a crucial role in its durability. Manufacturers can customize polyester belts to meet specific operational requirements, such as varying thicknesses, widths, and surface textures. This customization ensures that the belts can perform optimally in diverse applications, from food processing to industrial drying. By tailoring the belts to the unique demands of each manufacturing process, companies can further enhance the longevity and effectiveness of their drying systems.

In conclusion, the durability and longevity of polyester drying fabric belts position them as a forward-thinking solution in the manufacturing industry. Their ability to withstand harsh conditions, coupled with their resistance to environmental factors and ease of maintenance, makes them a superior choice for businesses seeking reliable and efficient drying solutions. As industries continue to evolve and demand more from their equipment, polyester drying fabric belts are poised to play a crucial role in shaping the future of manufacturing. By investing in these advanced materials, manufacturers can not only improve their operational efficiency but also contribute to a more sustainable and cost-effective production process.

Enhanced Efficiency in Manufacturing Processes

In the ever-evolving landscape of manufacturing, the quest for enhanced efficiency remains a paramount objective for industry leaders. One of the most significant advancements contributing to this goal is the adoption of polyester drying fabric belts. These innovative materials are revolutionizing the way manufacturers approach drying processes, leading to substantial improvements in productivity and operational effectiveness. As industries strive to optimize their workflows, the integration of polyester drying fabric belts emerges as a pivotal solution.

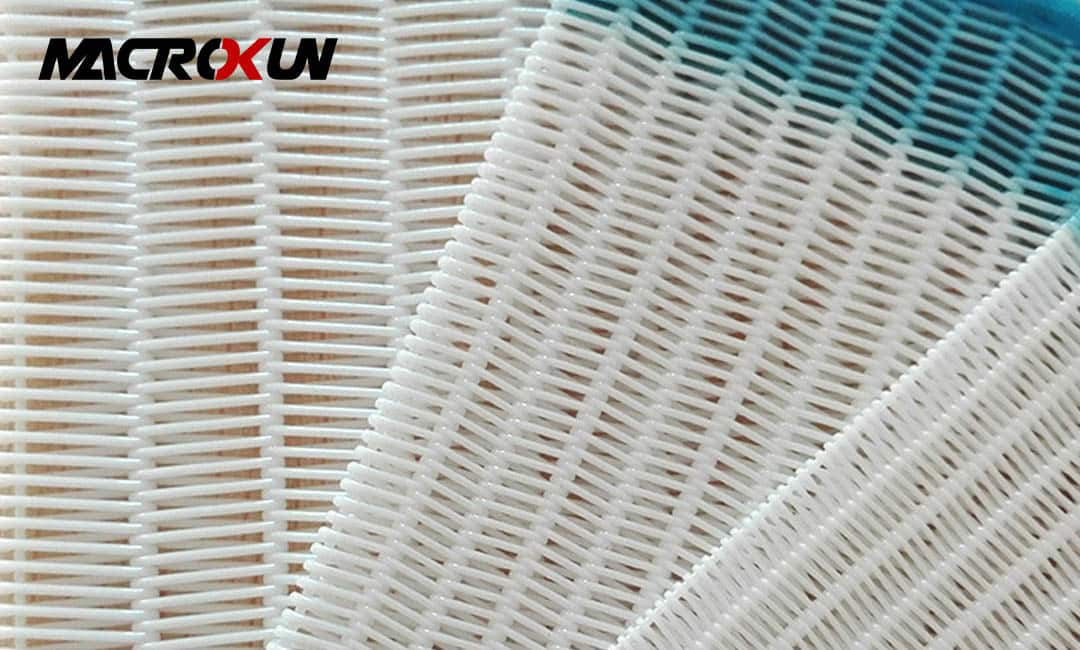

To begin with, polyester drying fabric belts are engineered to provide superior moisture removal capabilities. Unlike traditional drying methods that often rely on inefficient systems, these belts facilitate a more uniform and rapid drying process. This is primarily due to their unique construction, which allows for better air circulation and moisture evaporation. As a result, manufacturers can achieve faster drying times, thereby reducing the overall production cycle. This efficiency not only accelerates output but also minimizes energy consumption, aligning with the growing emphasis on sustainability in manufacturing practices.

Moreover, the durability of polyester drying fabric belts plays a crucial role in enhancing manufacturing efficiency. These belts are designed to withstand the rigors of continuous operation, exhibiting resistance to wear and tear that often plagues conventional drying systems. This longevity translates into reduced maintenance costs and less frequent replacements, allowing manufacturers to allocate resources more effectively. Consequently, the operational downtime associated with equipment failure is significantly diminished, further contributing to a seamless production flow.

In addition to their durability, polyester drying fabric belts offer versatility that is essential in modern manufacturing environments. They can be tailored to meet the specific requirements of various applications, whether in textiles, food processing, or paper production. This adaptability ensures that manufacturers can implement these belts across diverse processes, thereby standardizing equipment and simplifying training for personnel. As a result, the integration of polyester drying fabric belts fosters a more cohesive manufacturing strategy, ultimately leading to enhanced efficiency.

Furthermore, the implementation of polyester drying fabric belts is supported by advancements in technology. Many manufacturers are now utilizing automated systems that integrate these belts into their production lines. This automation not only streamlines the drying process but also allows for real-time monitoring and adjustments. By leveraging data analytics, manufacturers can optimize drying parameters, ensuring that each batch is processed under ideal conditions. This level of precision not only improves product quality but also reduces waste, further enhancing overall efficiency.

As industries continue to face increasing pressure to improve productivity while maintaining quality standards, the role of polyester drying fabric belts becomes increasingly significant. Their ability to deliver faster drying times, reduce maintenance costs, and adapt to various applications positions them as a cornerstone of modern manufacturing processes. Moreover, the integration of these belts into automated systems exemplifies the synergy between technology and material innovation, paving the way for a more efficient future.

In conclusion, the shift towards polyester drying fabric belts represents a transformative step in the pursuit of enhanced efficiency in manufacturing. By addressing key challenges such as drying time, durability, and adaptability, these belts are not only improving operational workflows but also contributing to a more sustainable manufacturing landscape. As industries embrace these advancements, it is clear that polyester drying fabric belts are not merely a trend but a fundamental component of the future of manufacturing.

Environmental Benefits of Using Polyester Materials

Polyester drying fabric belts are becoming increasingly popular in the manufacturing industry due to their numerous benefits, particularly in terms of environmental sustainability. Polyester is a synthetic fiber that is derived from petroleum, making it a versatile and durable material that is ideal for a wide range of applications. When it comes to drying fabric belts, polyester offers several advantages over traditional materials such as cotton or nylon.

One of the key environmental benefits of using polyester drying fabric belts is their longevity. Polyester is a highly durable material that can withstand high temperatures and heavy loads, making it ideal for use in industrial settings. Unlike natural fibers like cotton, polyester does not degrade as quickly and can be used for a longer period of time before needing to be replaced. This means that manufacturers can reduce their overall consumption of materials and lower their environmental impact by using polyester drying fabric belts.

In addition to their durability, polyester drying fabric belts are also more energy-efficient than other materials. Polyester has a lower thermal conductivity than materials like cotton, which means that it requires less energy to heat up and maintain a consistent temperature. This can result in significant cost savings for manufacturers, as well as a reduced carbon footprint. By using polyester drying fabric belts, companies can lower their energy consumption and decrease their reliance on fossil fuels, helping to mitigate the effects of climate change.

Another environmental benefit of using polyester drying fabric belts is their recyclability. Polyester is a thermoplastic material, which means that it can be melted down and reformed into new products. This makes polyester a highly sustainable material that can be reused multiple times, reducing the amount of waste that ends up in landfills. By choosing polyester drying fabric belts, manufacturers can contribute to a circular economy and minimize their impact on the environment.

Furthermore, polyester drying fabric belts are also resistant to mold, mildew, and bacteria, making them a hygienic choice for manufacturing processes. Unlike natural fibers, polyester does not absorb moisture as easily, which helps to prevent the growth of harmful microorganisms. This can improve the overall cleanliness and safety of manufacturing facilities, reducing the risk of contamination and ensuring a higher quality end product.

Overall, the environmental benefits of using polyester drying fabric belts make them a smart choice for manufacturers looking to reduce their impact on the planet. From their durability and energy efficiency to their recyclability and hygienic properties, polyester drying fabric belts offer a range of advantages that can help companies operate more sustainably. By investing in polyester materials, manufacturers can not only improve their bottom line but also contribute to a greener, more environmentally friendly future for the manufacturing industry as a whole.