Why Spiral Dryer Fabric Is Essential for Textile Manufacturing

Enhanced Drying Efficiency

In the realm of textile manufacturing, the efficiency of drying processes plays a pivotal role in determining the overall productivity and quality of the final product. One of the most significant advancements in this area is the introduction of spiral dryer fabric, which has revolutionized the way textiles are dried. This innovative fabric not only enhances drying efficiency but also contributes to improved operational performance in various manufacturing settings.

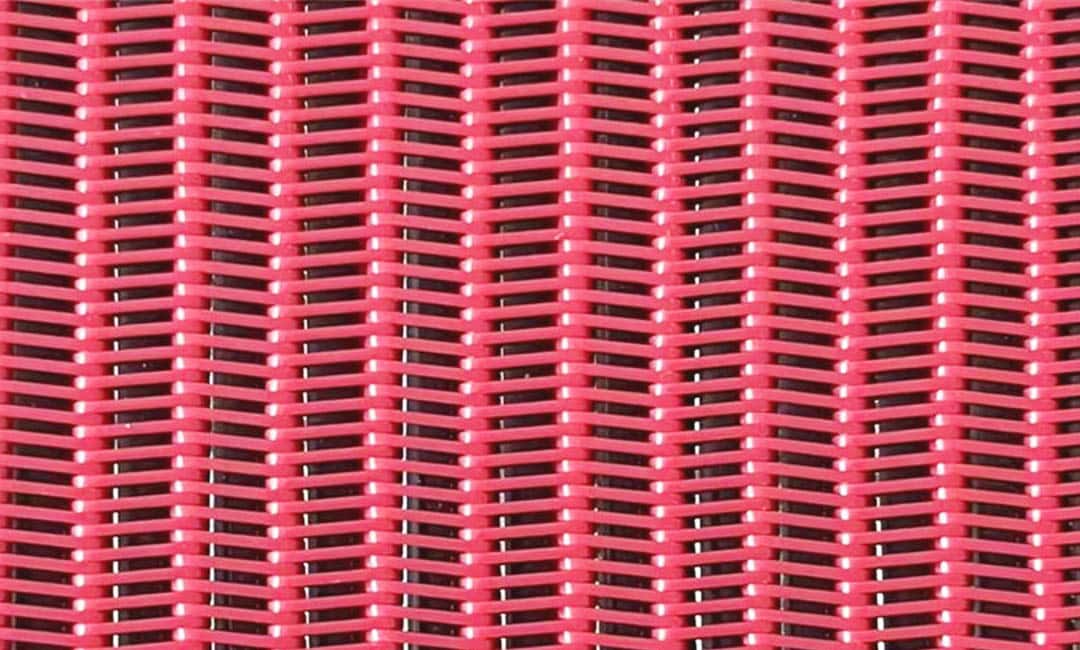

To begin with, the design of spiral dryer fabric is inherently conducive to optimal airflow and moisture removal. Unlike traditional drying methods that often rely on flat surfaces, spiral dryer fabrics are engineered to facilitate a continuous flow of air through the fabric. This unique structure allows for a more uniform distribution of heat and air, which is crucial for effective moisture evaporation. As a result, textiles can be dried more quickly and evenly, reducing the risk of uneven drying that can lead to defects in the final product.

Moreover, the enhanced drying efficiency provided by spiral dryer fabric translates directly into energy savings. In an industry where energy costs can significantly impact the bottom line, the ability to dry textiles more rapidly means that manufacturers can operate at lower energy consumption levels. This not only reduces operational costs but also aligns with the growing emphasis on sustainability within the textile sector. By minimizing energy usage, manufacturers can contribute to a more environmentally friendly production process, which is increasingly important to consumers and regulatory bodies alike.

In addition to energy savings, the use of spiral dryer fabric can lead to increased production capacity. With faster drying times, manufacturers can process larger volumes of textiles in a shorter period. This increased throughput is particularly beneficial in high-demand scenarios, where meeting customer orders promptly is essential for maintaining competitive advantage. Consequently, the integration of spiral dryer fabric into textile manufacturing processes can significantly enhance overall operational efficiency, allowing businesses to respond more effectively to market demands.

Furthermore, the durability and longevity of spiral dryer fabrics contribute to their essential role in textile manufacturing. These fabrics are designed to withstand the rigors of continuous use, which means that they require less frequent replacement compared to traditional drying materials. This durability not only reduces maintenance costs but also minimizes downtime associated with fabric replacement, thereby further enhancing productivity. Manufacturers can rely on spiral dryer fabrics to maintain consistent performance over time, ensuring that their drying processes remain efficient and effective.

In addition to these practical benefits, the use of spiral dryer fabric also supports the production of higher-quality textiles. The uniform drying achieved through this technology helps to preserve the integrity of the fabric, preventing issues such as shrinkage or distortion that can occur with uneven drying methods. As a result, manufacturers can produce textiles that meet stringent quality standards, which is essential for maintaining customer satisfaction and brand reputation.

In conclusion, the importance of spiral dryer fabric in textile manufacturing cannot be overstated. Its ability to enhance drying efficiency, reduce energy consumption, increase production capacity, and improve product quality makes it an indispensable component of modern textile processing. As the industry continues to evolve, the adoption of such innovative technologies will be crucial for manufacturers seeking to optimize their operations and remain competitive in a rapidly changing market.

Improved Fabric Quality

In the realm of textile manufacturing, the quality of the final product is paramount, and one of the critical components that significantly influences this quality is the spiral dryer fabric. This specialized fabric plays a vital role in the drying process of textiles, ensuring that the finished goods meet the high standards expected by consumers and manufacturers alike. The importance of improved fabric quality cannot be overstated, as it directly impacts not only the aesthetic appeal of the textiles but also their durability and performance.

To begin with, spiral dryer fabrics are designed to provide uniform drying across the entire surface of the textile. This uniformity is crucial because uneven drying can lead to variations in color, texture, and overall quality. When textiles are subjected to inconsistent drying conditions, certain areas may retain moisture longer than others, resulting in a range of issues such as mold growth, color bleeding, and even structural weaknesses. By utilizing spiral dryer fabrics, manufacturers can ensure that moisture is removed evenly, thereby enhancing the overall quality of the fabric.

Moreover, the design of spiral dryer fabrics allows for optimal airflow and heat distribution during the drying process. This is particularly important because effective moisture removal is essential for achieving the desired fabric characteristics. For instance, fabrics that are dried too quickly may become brittle, while those that are dried too slowly may not achieve the necessary finish. The ability of spiral dryer fabrics to facilitate controlled drying conditions helps to mitigate these risks, leading to textiles that are not only visually appealing but also possess the desired tactile qualities.

In addition to promoting uniform drying, spiral dryer fabrics contribute to the preservation of the fabric’s integrity. The gentle yet effective drying process minimizes the risk of damage that can occur with harsher drying methods. For example, traditional drying techniques may subject textiles to excessive heat or mechanical stress, which can compromise the fibers and lead to fraying or distortion. In contrast, the use of spiral dryer fabrics allows for a more delicate approach, ensuring that the fabric maintains its original structure and appearance. This preservation of quality is particularly important for high-end textiles, where consumers expect nothing less than perfection.

Furthermore, the longevity of spiral dryer fabrics themselves plays a role in improving fabric quality. These fabrics are engineered to withstand the rigors of the drying process, which means they can maintain their performance over time. As a result, manufacturers can rely on consistent results batch after batch, leading to a more stable production process. This reliability not only enhances the quality of the textiles produced but also contributes to overall operational efficiency, as manufacturers can reduce downtime and waste associated with fabric replacement.

In conclusion, the significance of spiral dryer fabric in textile manufacturing cannot be overlooked, particularly when it comes to improving fabric quality. By ensuring uniform drying, facilitating optimal airflow, preserving fabric integrity, and offering durability, these specialized fabrics play an essential role in producing high-quality textiles. As the textile industry continues to evolve, the reliance on advanced technologies such as spiral dryer fabrics will undoubtedly remain a cornerstone of quality assurance, ultimately benefiting both manufacturers and consumers alike. The commitment to excellence in fabric quality is a testament to the industry’s dedication to meeting the ever-increasing demands of the market.

Cost-Effectiveness in Production

In the realm of textile manufacturing, the efficiency and effectiveness of production processes are paramount. One of the critical components that significantly influences these factors is the spiral dryer fabric. This specialized fabric plays a vital role in the drying phase of textile production, and its cost-effectiveness is a key consideration for manufacturers aiming to optimize their operations. By understanding the various ways in which spiral dryer fabric contributes to cost savings, manufacturers can make informed decisions that enhance their overall productivity and profitability.

To begin with, spiral dryer fabric is designed to facilitate efficient moisture removal from textiles during the drying process. This efficiency is crucial, as the drying stage can often be a bottleneck in production lines. When moisture is removed quickly and uniformly, it not only accelerates the overall drying time but also reduces energy consumption. Consequently, manufacturers can lower their operational costs, as less energy is required to achieve the desired moisture content in the finished products. This reduction in energy usage translates directly into financial savings, making spiral dryer fabric an economically viable choice for textile producers.

Moreover, the durability of spiral dryer fabric further contributes to its cost-effectiveness. Unlike traditional drying methods that may require frequent replacements of materials, spiral dryer fabrics are engineered to withstand the rigors of continuous use. Their robust construction ensures a longer lifespan, which means that manufacturers can minimize the costs associated with fabric replacement and maintenance. This longevity not only reduces direct expenses but also lessens downtime in production, allowing for a more streamlined manufacturing process. As a result, the initial investment in high-quality spiral dryer fabric can yield significant returns over time.

In addition to energy savings and durability, the versatility of spiral dryer fabric enhances its cost-effectiveness. These fabrics can be tailored to meet the specific needs of various textile types, accommodating different weights, thicknesses, and moisture levels. This adaptability allows manufacturers to optimize their drying processes for a wide range of products, thereby increasing their production capabilities without the need for extensive modifications to existing equipment. By utilizing spiral dryer fabric that is compatible with multiple textile applications, manufacturers can achieve greater flexibility in their operations, ultimately leading to improved efficiency and reduced costs.

Furthermore, the use of spiral dryer fabric can also lead to enhanced product quality, which is an essential aspect of cost-effectiveness in textile manufacturing. When moisture is removed uniformly and efficiently, the risk of defects such as shrinkage, distortion, or uneven drying is significantly reduced. High-quality finished products not only meet customer expectations but also minimize the costs associated with returns, rework, or waste. Therefore, investing in spiral dryer fabric not only streamlines production but also ensures that the end products maintain a high standard, further solidifying the financial benefits for manufacturers.

In conclusion, the cost-effectiveness of spiral dryer fabric in textile manufacturing cannot be overstated. By improving energy efficiency, extending durability, offering versatility, and enhancing product quality, this specialized fabric serves as a crucial element in optimizing production processes. As manufacturers continue to seek ways to reduce costs while maintaining high standards of quality, the adoption of spiral dryer fabric emerges as a strategic choice that aligns with their operational goals. Ultimately, the integration of this innovative material into textile production not only fosters economic benefits but also supports the industry’s ongoing evolution towards greater efficiency and sustainability.