Why Spiral Fabric Dryer Belts Are Ideal for Textile and Paper Industries

Increased Efficiency in Drying Process

In the textile and paper industries, the drying process is a critical step in the production of high-quality products. Efficient drying not only ensures that the final product meets the required specifications but also plays a significant role in reducing production costs and increasing overall productivity. One key component that can greatly impact the efficiency of the drying process is the type of conveyor belt used in the dryer.

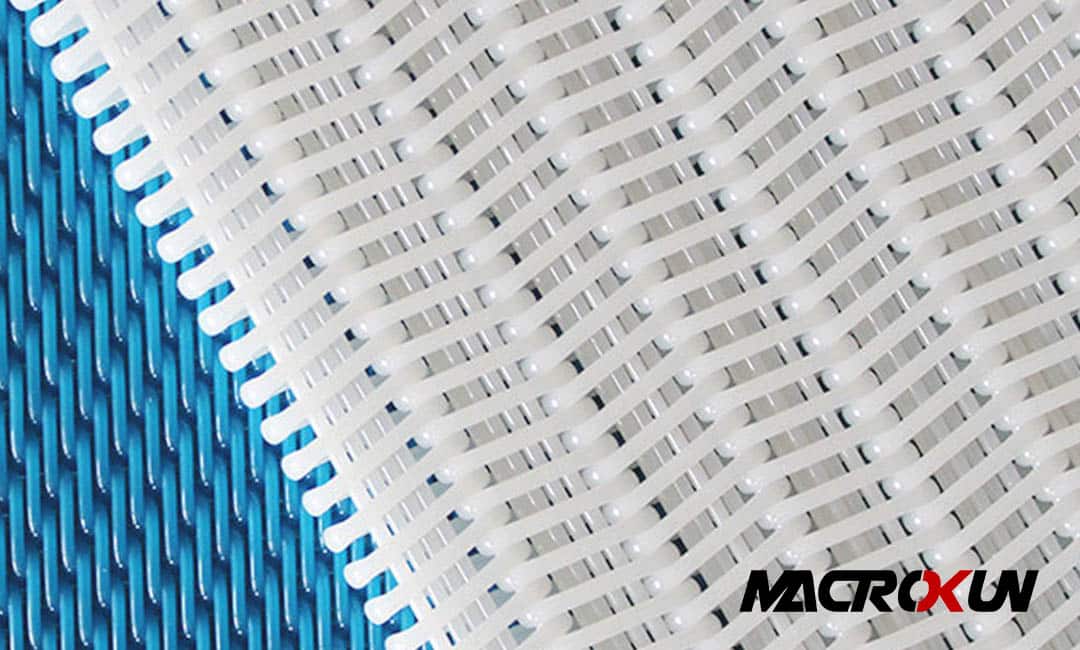

Spiral fabric dryer belts have become increasingly popular in the textile and paper industries due to their unique design and numerous benefits. These belts are made from a continuous loop of spiral wires that are connected by cross rods. This design allows for excellent air circulation and heat transfer, resulting in faster and more uniform drying of the materials being processed.

One of the main advantages of spiral fabric dryer belts is their open mesh construction, which allows for optimal airflow through the belt. This ensures that hot air can easily penetrate the material being dried, leading to faster drying times and more consistent results. Additionally, the open mesh design helps to prevent overheating and uneven drying, which can result in lower-quality products and increased production costs.

Another key benefit of spiral fabric dryer belts is their high strength and durability. These belts are made from high-quality materials that can withstand the high temperatures and heavy loads typically encountered in industrial drying processes. This means that spiral fabric dryer belts are less likely to stretch, warp, or break under pressure, resulting in longer belt life and reduced maintenance costs.

In addition to their superior performance and durability, spiral fabric dryer belts are also easy to clean and maintain. The open mesh design allows for easy access to the belt surface, making it simple to remove any debris or buildup that may accumulate during the drying process. This not only helps to maintain optimal drying efficiency but also ensures that the final product meets the required quality standards.

Overall, spiral fabric dryer belts offer a range of benefits that make them ideal for use in the textile and paper industries. Their open mesh construction allows for excellent airflow and heat transfer, resulting in faster and more uniform drying of materials. Additionally, their high strength and durability ensure long-lasting performance and reduced maintenance costs. With these advantages, it is no wonder that spiral fabric dryer belts have become the preferred choice for many manufacturers looking to increase efficiency in their drying processes.

In conclusion, spiral fabric dryer belts are an ideal choice for the textile and paper industries due to their superior performance, durability, and ease of maintenance. By investing in high-quality spiral fabric dryer belts, manufacturers can improve the efficiency of their drying processes, reduce production costs, and ultimately produce higher-quality products. With these benefits in mind, it is clear that spiral fabric dryer belts are a valuable asset for any manufacturer looking to optimize their drying operations.

Enhanced Durability and Longevity

Spiral fabric dryer belts are an essential component in the textile and paper industries, providing a reliable and efficient means of drying materials during the production process. These belts are designed to withstand high temperatures and heavy loads, making them ideal for use in industrial settings where durability and longevity are paramount.

One of the key advantages of spiral fabric dryer belts is their enhanced durability. Made from high-quality materials such as polyester and polyamide, these belts are able to withstand the rigors of continuous use in demanding industrial environments. The spiral design of the belts allows for excellent air circulation, ensuring that materials are dried quickly and efficiently without the risk of overheating or damage.

In addition to their durability, spiral fabric dryer belts are also known for their longevity. Unlike traditional conveyor belts, which can wear out quickly under heavy use, spiral fabric dryer belts are designed to last for years without needing to be replaced. This not only helps to reduce maintenance costs, but also ensures that production can continue uninterrupted, saving time and money in the long run.

Another benefit of spiral fabric dryer belts is their versatility. These belts can be customized to fit a wide range of applications, making them suitable for use in a variety of industries beyond just textiles and paper. Whether you are drying fabrics, paper products, or even food items, spiral fabric dryer belts can be tailored to meet your specific needs, ensuring optimal performance and efficiency.

Furthermore, spiral fabric dryer belts are easy to install and maintain, making them a cost-effective solution for businesses looking to improve their production processes. With proper care and maintenance, these belts can last for years without needing to be replaced, saving businesses time and money in the long run. Additionally, the spiral design of the belts allows for easy cleaning and maintenance, further reducing downtime and ensuring that production can continue uninterrupted.

In conclusion, spiral fabric dryer belts are an ideal choice for the textile and paper industries due to their enhanced durability, longevity, and versatility. These belts are designed to withstand high temperatures and heavy loads, making them a reliable and efficient solution for drying materials during the production process. With proper care and maintenance, spiral fabric dryer belts can last for years without needing to be replaced, saving businesses time and money in the long run. If you are looking for a cost-effective and reliable solution for drying materials in your industrial setting, consider investing in spiral fabric dryer belts for optimal performance and efficiency.

Improved Product Quality and Consistency

Spiral fabric dryer belts have become a popular choice for the textile and paper industries due to their numerous benefits. One of the key advantages of using spiral fabric dryer belts is the improved product quality and consistency that they offer. These belts are designed to provide a smooth and uniform surface for the drying process, which helps to ensure that the final product is of high quality.

One of the main reasons why spiral fabric dryer belts are ideal for the textile and paper industries is their ability to provide even heat distribution. The spiral design of these belts allows for efficient heat transfer, which helps to ensure that the entire surface of the product is dried evenly. This is crucial for industries that require precise drying conditions to achieve the desired product quality.

In addition to providing even heat distribution, spiral fabric dryer belts also offer excellent air permeability. This allows for efficient air flow through the belt, which helps to speed up the drying process and ensure that the product is dried thoroughly. The improved air permeability of spiral fabric dryer belts also helps to prevent overheating, which can lead to uneven drying and poor product quality.

Another benefit of using spiral fabric dryer belts is their durability and longevity. These belts are made from high-quality materials that are designed to withstand the rigors of industrial drying processes. This means that they can withstand high temperatures, heavy loads, and constant use without experiencing wear and tear. As a result, spiral fabric dryer belts are a cost-effective solution for industries that require reliable and long-lasting equipment.

Furthermore, spiral fabric dryer belts are easy to clean and maintain, which helps to ensure that they remain in optimal condition for extended periods of time. This is important for industries that require consistent product quality and efficiency in their drying processes. By using spiral fabric dryer belts, companies can minimize downtime and maintenance costs, while maximizing productivity and profitability.

Overall, spiral fabric dryer belts are an ideal choice for the textile and paper industries due to their ability to improve product quality and consistency. These belts offer even heat distribution, excellent air permeability, durability, and ease of maintenance, making them a reliable and cost-effective solution for industrial drying processes. By investing in spiral fabric dryer belts, companies can enhance their production processes and achieve superior results in terms of product quality and efficiency.