Why Ultipleat High Flow Filters Are Ideal for High-Capacity Systems

Increased Filtration Efficiency

In the world of industrial filtration, efficiency is key. High-capacity systems require filters that can handle large volumes of liquid while maintaining high levels of filtration efficiency. Ultipleat High Flow Filters are designed to meet these demands, making them ideal for high-capacity systems in a variety of industries.

One of the key benefits of Ultipleat High Flow Filters is their increased filtration efficiency. These filters are designed with a large surface area, allowing for greater contact between the filter media and the liquid being filtered. This increased surface area results in more effective filtration, capturing a higher percentage of contaminants and ensuring cleaner liquid output.

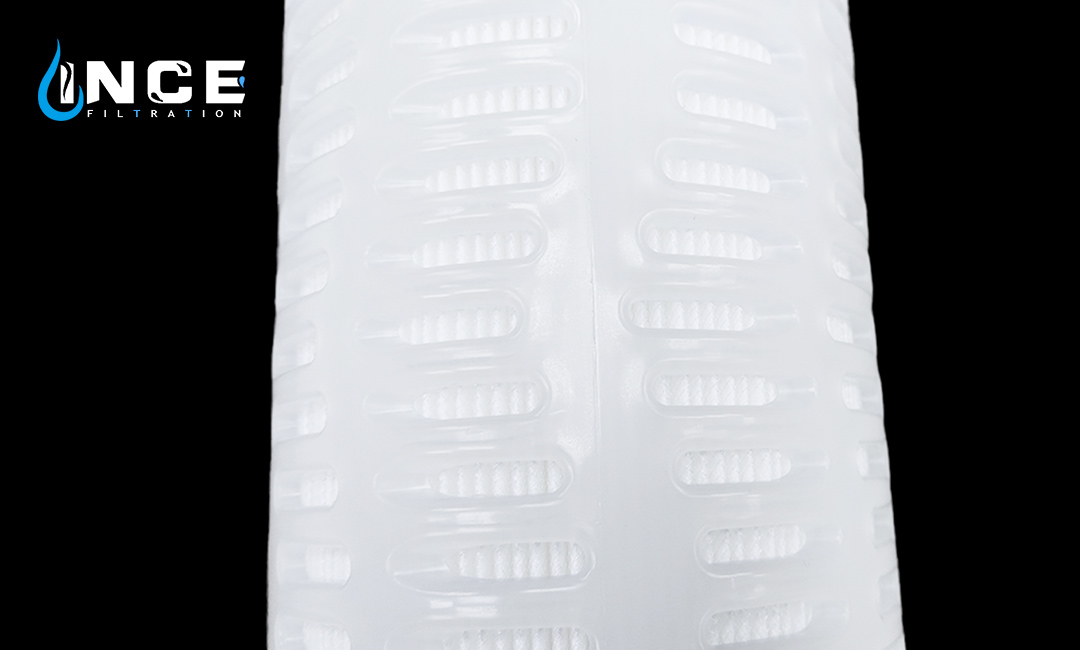

In addition to their large surface area, Ultipleat High Flow Filters are also designed with a graded density structure. This means that the filter media is denser on the outside and becomes progressively less dense towards the center of the filter. This design allows for more efficient filtration, as larger particles are captured on the outer layers while smaller particles are captured deeper within the filter. The result is a more thorough filtration process that removes a wider range of contaminants from the liquid.

Another factor that contributes to the increased filtration efficiency of Ultipleat High Flow Filters is their high flow rates. These filters are designed to handle large volumes of liquid, allowing for faster filtration and higher throughput. This means that high-capacity systems can operate more efficiently with Ultipleat High Flow Filters, reducing downtime and increasing productivity.

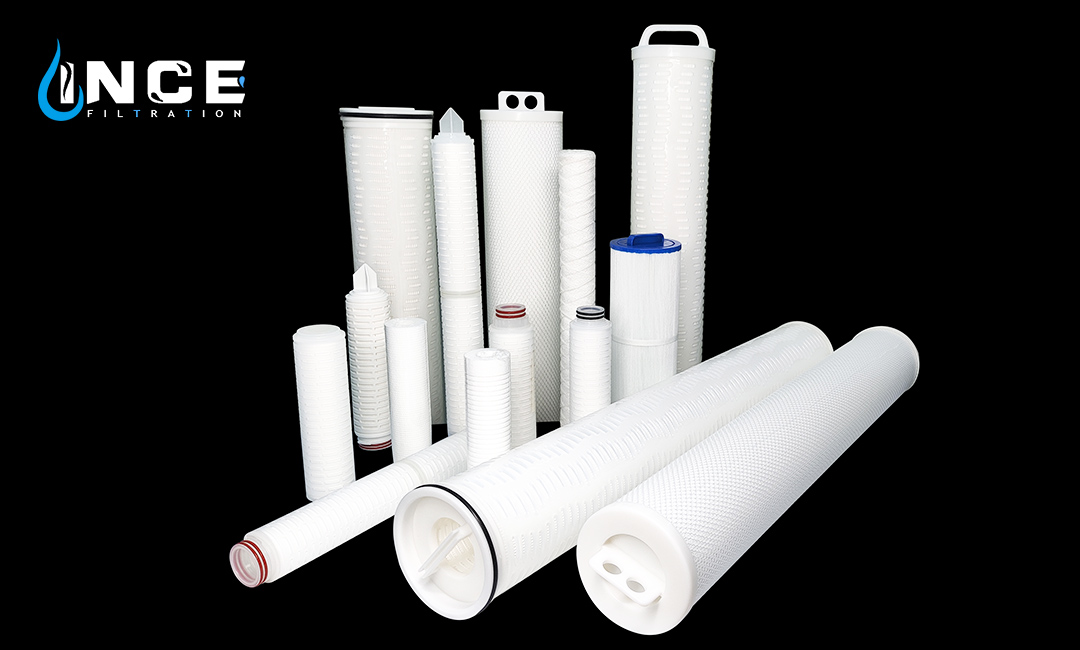

Ultipleat High Flow Filters are also designed for easy maintenance, with a simple and quick replacement process. This means that filters can be changed out without disrupting operations, keeping high-capacity systems running smoothly and efficiently. Additionally, Ultipleat High Flow Filters are compatible with a wide range of liquids and can be customized to meet specific filtration requirements, making them versatile and adaptable to a variety of applications.

In conclusion, Ultipleat High Flow Filters are ideal for high-capacity systems due to their increased filtration efficiency. With a large surface area, graded density structure, high flow rates, and easy maintenance, these filters are designed to handle the demands of industrial filtration with ease. Whether filtering water, chemicals, or other liquids, Ultipleat High Flow Filters provide a reliable and effective solution for high-capacity systems in a variety of industries.

Reduced Maintenance Costs

Reduced Maintenance Costs

When it comes to high-capacity systems, one of the biggest concerns for operators is the cost of maintenance. Traditional filters often require frequent replacements and extensive cleaning, which can quickly add up in terms of both time and money. However, Ultipleat High Flow Filters offer a solution to this problem, as they are specifically designed to reduce maintenance costs.

One of the key features of Ultipleat High Flow Filters is their large surface area. Unlike traditional filters, which have a limited surface area, these filters have a much larger area for filtration. This means that they can capture more contaminants and particles, allowing for longer filter life. With a longer filter life, operators can reduce the frequency of filter replacements, saving both time and money.

In addition to their large surface area, Ultipleat High Flow Filters also have a unique design that allows for easy cleaning. Traditional filters often require extensive cleaning procedures, which can be time-consuming and costly. However, Ultipleat High Flow Filters can be easily cleaned by backwashing, a process that involves reversing the flow of water through the filter. This removes any accumulated particles and contaminants, restoring the filter to its original efficiency. By eliminating the need for complex cleaning procedures, Ultipleat High Flow Filters further reduce maintenance costs.

Furthermore, Ultipleat High Flow Filters are designed to withstand high pressures and flow rates. This means that they can handle the demands of high-capacity systems without compromising their performance. Traditional filters may struggle to maintain their efficiency under high pressures, leading to more frequent replacements and increased maintenance costs. However, Ultipleat High Flow Filters are specifically engineered to handle these conditions, ensuring that they can deliver consistent and reliable filtration over an extended period of time.

Another factor that contributes to the reduced maintenance costs of Ultipleat High Flow Filters is their compatibility with a wide range of fluids. These filters can effectively filter various fluids, including water, chemicals, and oils. This versatility eliminates the need for multiple filter types, simplifying the maintenance process and reducing costs associated with stocking and replacing different filters for different fluids.

In conclusion, Ultipleat High Flow Filters are an ideal choice for high-capacity systems due to their ability to reduce maintenance costs. With their large surface area, easy cleaning process, and ability to withstand high pressures and flow rates, these filters offer a longer filter life and minimize the need for frequent replacements. Additionally, their compatibility with various fluids eliminates the need for multiple filter types, further reducing maintenance costs. By investing in Ultipleat High Flow Filters, operators can not only save money but also ensure the efficient and reliable operation of their high-capacity systems.

Longer Service Life

In the realm of filtration technology, the longevity and efficiency of filter systems are paramount, particularly in high-capacity applications. Ultipleat High Flow Filters stand out as a superior choice for such systems, primarily due to their extended service life. This characteristic not only enhances operational efficiency but also contributes to significant cost savings over time. The design and engineering of these filters are specifically tailored to meet the demands of high-flow environments, ensuring that they can handle increased volumes without compromising performance.

One of the key factors contributing to the longer service life of Ultipleat High Flow Filters is their unique pleated design. This design maximizes the surface area available for filtration, allowing for a greater volume of fluid to pass through while maintaining optimal flow rates. As a result, the filters can capture a higher quantity of contaminants before reaching their saturation point. This increased capacity means that the filters do not require frequent replacements, which is a common issue with traditional filter designs that often become clogged quickly under high-flow conditions.

Moreover, the materials used in the construction of Ultipleat High Flow Filters are engineered to withstand the rigors of demanding applications. These filters are typically made from high-quality synthetic media that exhibit excellent chemical compatibility and resistance to degradation. This durability ensures that the filters maintain their structural integrity over time, even when exposed to harsh operating conditions. Consequently, users can rely on these filters to perform consistently, reducing the likelihood of unexpected failures that can disrupt operations and lead to costly downtime.

In addition to their robust construction, Ultipleat High Flow Filters are designed to facilitate easy maintenance and replacement. The filters are often equipped with features that allow for quick and straightforward installation, which minimizes the time and labor required for service. This ease of maintenance is particularly beneficial in high-capacity systems where operational efficiency is critical. By reducing the frequency and complexity of filter changes, organizations can focus on their core activities rather than being bogged down by maintenance tasks.

Furthermore, the longer service life of Ultipleat High Flow Filters translates into environmental benefits. With fewer filters needing to be disposed of, there is a reduction in waste generated from filter replacements. This aspect aligns with the growing emphasis on sustainability in industrial practices, as companies seek to minimize their environmental footprint. By choosing filters that last longer, organizations not only save on costs but also contribute to more sustainable operations.

In conclusion, the extended service life of Ultipleat High Flow Filters makes them an ideal choice for high-capacity systems. Their innovative pleated design, combined with durable materials and ease of maintenance, ensures that they can handle the demands of high-flow applications effectively. As industries continue to prioritize efficiency and sustainability, the adoption of such advanced filtration solutions will likely become increasingly prevalent. Ultimately, investing in Ultipleat High Flow Filters not only enhances operational performance but also supports a more sustainable approach to industrial filtration. By recognizing the advantages of these filters, organizations can make informed decisions that benefit both their operations and the environment.

Enhanced System Performance

In the realm of filtration technology, the Ultipleat High Flow Filters stand out as a pivotal solution for high-capacity systems, particularly due to their ability to enhance overall system performance. These filters are designed to accommodate large volumes of fluid while maintaining optimal flow rates, which is essential in various industrial applications. The unique construction of Ultipleat filters, characterized by their pleated design, significantly increases the surface area available for filtration. This feature not only allows for a higher dirt-holding capacity but also ensures that the filters can operate efficiently over extended periods without frequent replacements.

Moreover, the efficiency of Ultipleat High Flow Filters is further augmented by their ability to minimize pressure drop across the filter media. A lower pressure drop translates to reduced energy consumption, which is a critical factor in high-capacity systems where operational costs can escalate quickly. By maintaining a consistent flow rate while minimizing energy expenditure, these filters contribute to a more sustainable and cost-effective filtration process. This efficiency is particularly beneficial in applications such as water treatment, chemical processing, and food and beverage production, where maintaining product quality and system reliability is paramount.

In addition to their energy efficiency, Ultipleat High Flow Filters are engineered to provide superior contaminant removal capabilities. The advanced materials used in their construction allow for the effective capture of a wide range of particulate matter, including fine particles that may otherwise compromise system integrity. This capability not only protects downstream equipment but also enhances the overall quality of the end product. As a result, industries that rely on high-capacity filtration systems can achieve greater consistency and reliability in their operations, ultimately leading to improved customer satisfaction.

Furthermore, the design of Ultipleat filters facilitates easy installation and maintenance, which is another critical aspect of enhanced system performance. The filters are typically available in various configurations, allowing for seamless integration into existing systems. This adaptability ensures that operators can quickly replace or service filters without significant downtime, thereby maintaining continuous operation. The reduced maintenance frequency associated with these filters also contributes to lower operational costs, as fewer resources are required for filter changes and system checks.

Transitioning from the technical advantages, it is essential to consider the broader implications of utilizing Ultipleat High Flow Filters in high-capacity systems. The enhanced performance not only leads to operational efficiencies but also supports compliance with stringent regulatory standards. Industries are increasingly held accountable for their environmental impact, and the ability to maintain high-quality output while minimizing waste is crucial. By employing advanced filtration solutions like Ultipleat filters, companies can demonstrate their commitment to sustainability and responsible resource management.

In conclusion, the Ultipleat High Flow Filters represent a significant advancement in filtration technology, particularly for high-capacity systems. Their ability to enhance system performance through increased dirt-holding capacity, reduced pressure drop, superior contaminant removal, and ease of maintenance makes them an ideal choice for various industrial applications. As industries continue to seek ways to improve efficiency and sustainability, the adoption of such innovative filtration solutions will undoubtedly play a vital role in shaping the future of operational excellence. By investing in Ultipleat High Flow Filters, organizations can not only optimize their processes but also position themselves as leaders in their respective fields, committed to quality and environmental stewardship.